A kind of liquefaction device and liquefaction method for preparing starch sugar

A technology for liquefaction device and starch sugar, which is applied in the directions of biochemical cleaning device, biochemical equipment and method, biological material sampling method, etc., can solve the problems of insufficient protein flocculation, inability to remove, and quality reduction of starch sugar products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Transport the starch milk with a temperature of 35°C, a pH value of 5.8, and a mass concentration of 33% to the liquefaction injector, and hydrolyze it at 116°C and 0.28MPa for 2 minutes to obtain hydrolyzed starch milk;

[0052] Transfer the hydrolyzed starch milk to the flash tank, then add Novozymes 2X high-temperature-resistant amylase at 0.28kg per ton of dry starch, and flash at 101kPa and 98°C for 5min to obtain the flashed starch milk;

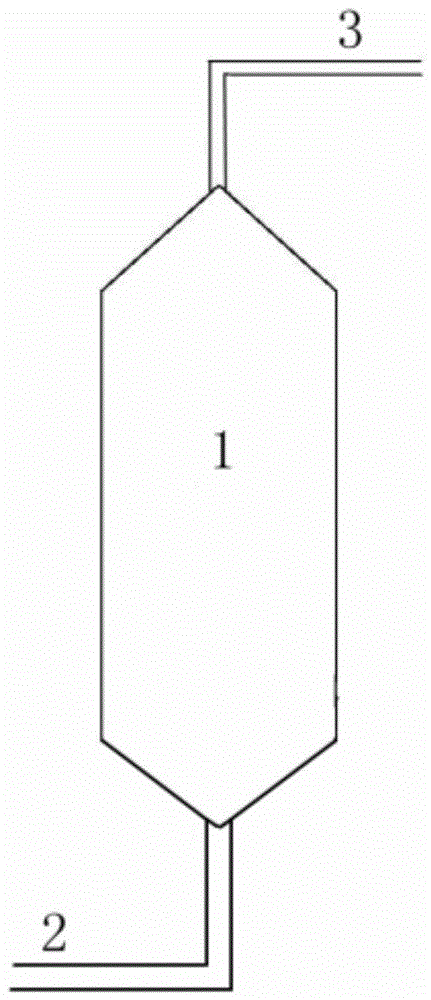

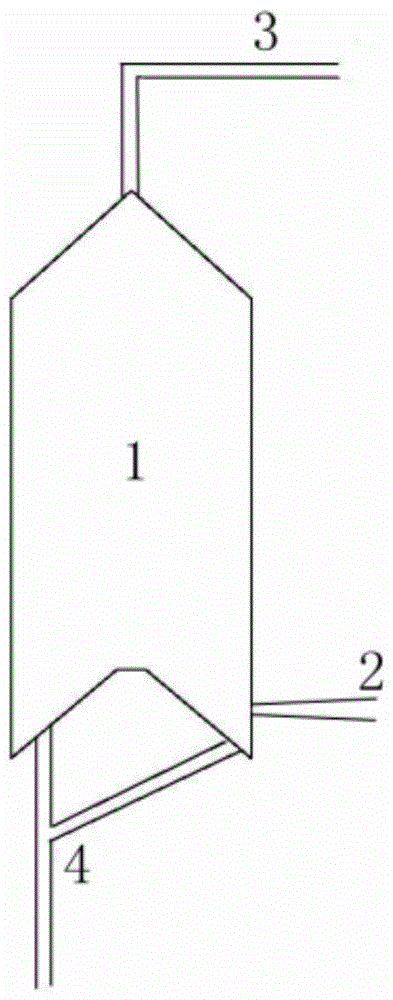

[0053] The flashed starch milk is transported to the liquefaction device described in the above technical solution. The liquefaction device is used in series with four liquefaction columns, and liquefied at 95°C for 100 minutes to obtain starch liquefaction liquid.

[0054] The present invention titrates the obtained starch liquefaction liquid, and tests its titration speed. The results are shown in Table 1. Table 1 shows the liquefaction effect data of the starch liquefaction liquid obtained in Examples 1-3 and Comparative Examp...

Embodiment 2

[0063] Transport the starch milk with a temperature of 40°C, a pH value of 6.0, and a mass concentration of 31% to the liquefaction injector, and hydrolyze it at 118°C and 0.3 MPa for 3 minutes to obtain hydrolyzed starch milk;

[0064] Transfer the hydrolyzed starch milk to the flash tank, then add Novozymes 2X high-temperature-resistant amylase at 0.26kg per ton of dry starch, and flash at 101kPa and 95°C for 5 minutes to obtain the flashed starch milk;

[0065] The flashed starch milk is transported to the liquefaction device described in the above technical solution. The liquefaction device is used in series with 6 liquefaction columns and liquefied at 98°C for 90 minutes to obtain starch liquefaction liquid.

[0066] The present invention titrates the obtained starch liquefaction liquid, and tests its titration speed, and the results are shown in Table 1.

[0067] In the present invention, the iodine reagent is added dropwise into the starch liquefaction liquid obtained i...

Embodiment 3

[0075] Transport the starch milk with a temperature of 45°C, a pH value of 6.0, and a mass concentration of 32% to the liquefaction injector, and hydrolyze it at 116°C and 0.3 MPa for 3 minutes to obtain hydrolyzed starch milk;

[0076] Transfer the hydrolyzed starch milk to the flash tank, then add Novozymes 2X high-temperature-resistant amylase at 0.27kg per kg of dry starch, and flash at 98kPa and 95°C for 5min to obtain the flashed starch milk;

[0077] The flashed starch milk is transported to the liquefaction device described in the above technical solution. The liquefaction device is used in series with five liquefaction columns, and is liquefied at 98° C. for 120 minutes to obtain starch liquefaction liquid.

[0078] The present invention titrates the obtained starch liquefaction liquid, and tests its titration speed, and the results are shown in Table 1.

[0079] In the present invention, the iodine reagent is added dropwise into the starch liquefaction liquid obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com