A dual-parameter tool position optimization method for five-axis side milling of non-developable ruled surfaces

A ruled surface and tool position optimization technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems that the scale factor cannot be adjusted adaptively, it is difficult to determine the scale factor, and the efficiency is low, so as to optimize the tool position trajectory, The effect of correct and effective methods and advanced methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

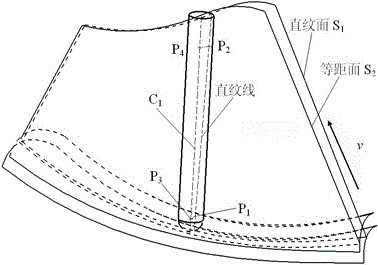

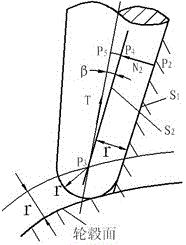

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below by taking a centrifugal impeller blade as an example in conjunction with the accompanying drawings.

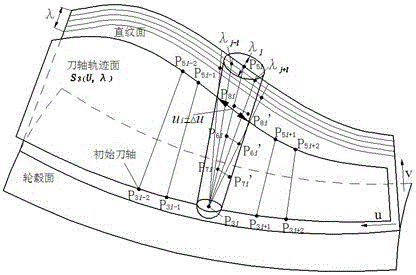

[0059] The present invention provides a non-developable ruled surface five-axis side milling dual-parameter tool position optimization method, which mainly includes the following steps:

[0060] 1) Discretize the ruled surface and establish the initial position of the cone cutter;

[0061] 2) Establish the initial direction error of the tool axis;

[0062] 3) Two-parameter tool position optimization to establish the optimal tool axis trajectory.

[0063] The discretization of the ruled surface includes the following steps:

[0064] 1) The u-direction of the non-developable ruled surface to be processed is divided into n processing tool positions;

[0065] 2) The v-direction parameter of the surface is divided into m eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com