Dry-type transformer cooling device with intelligent frequency conversion function and application method

A dry-type transformer and cooling device technology, which is used in transformer/inductor cooling, temperature control by electric means, etc., can solve the problems of overload and low resistance to short-circuit current, dry-type transformer burnout, short insulation life and other problems. Improve overload and short-circuit current resistance, improve refrigeration efficiency, and avoid the effect of emergency stop and emergency opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

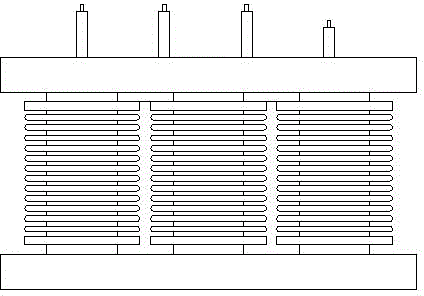

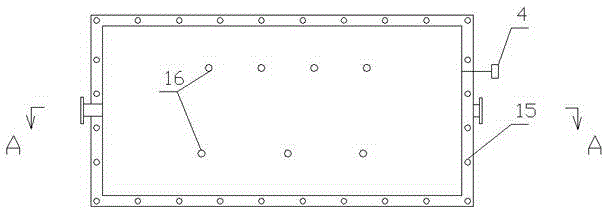

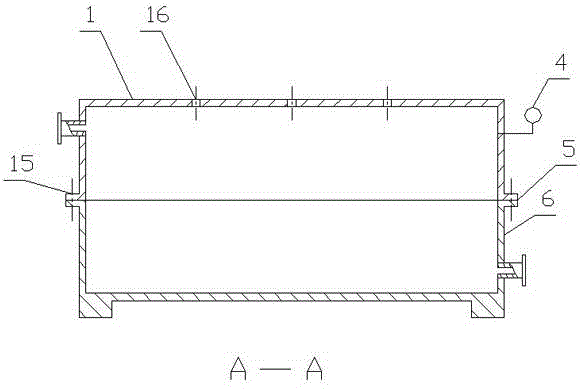

[0021] Such as Figure 1~8 As shown, a dry-type transformer cooling device with intelligent frequency conversion function includes a frequency conversion refrigeration compressor capable of automatically controlling the frequency to control the working output, a cooling chamber, a refrigeration system, and a control module. It is characterized in that: the cooling chamber is divided into It is an upper shell and a lower shell. There are round holes on the top of the upper shell for the high-voltage and low-voltage bushings of the dry-type transformer to pass through. The part of the bushing passing through the round hole is tightly sealed by a sealing ring. In the cavity of the cooling chamber, there is a refrigerant medium circulating in the cooling chamber, and the refrigeration system performs a refrigeration cycle on the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com