Yttrium-based superconducting tape with uniform contact resistance and its preparation method and device

A technology of superconducting tape and contact resistance, which is applied in the manufacture/processing of superconductor devices, superconductor parts and other directions, and achieves the effects of good uniformity, good ductility, and stable and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

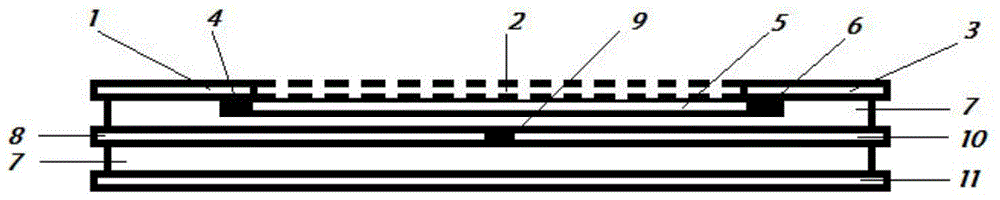

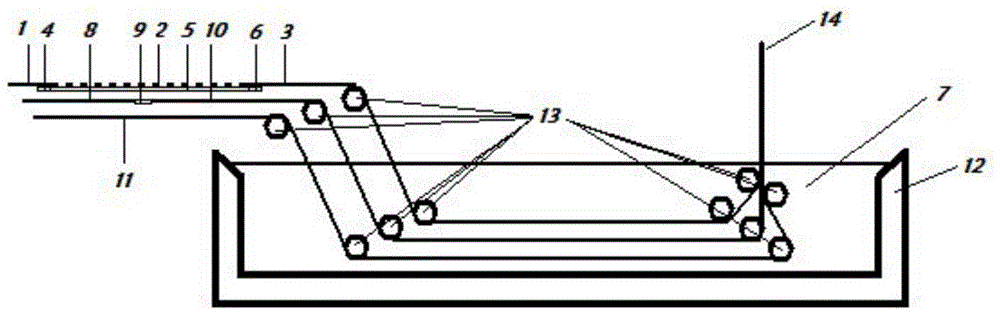

[0047] Such as figure 1 As shown, the present embodiment provides a yttrium-based superconducting strip with a uniform distribution of contact resistance, including a metal upper cladding layer, a superconducting strip central layer, a metal lower cladding layer, and an electrically connected welding metal layer. The central layer of the superconducting strip is arranged between the upper cladding layer of the metal and the lower cladding layer of the metal, between the upper cladding l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap