A high temperature gas wet dust removal device

A high-temperature gas, wet dust removal technology, applied in the field of iron and steel metallurgy, can solve the problems of automatic separation of dust precipitation, automatic adjustment of water level, complicated operation, etc., and achieve the effect of automatic separation of dust precipitation, compact structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

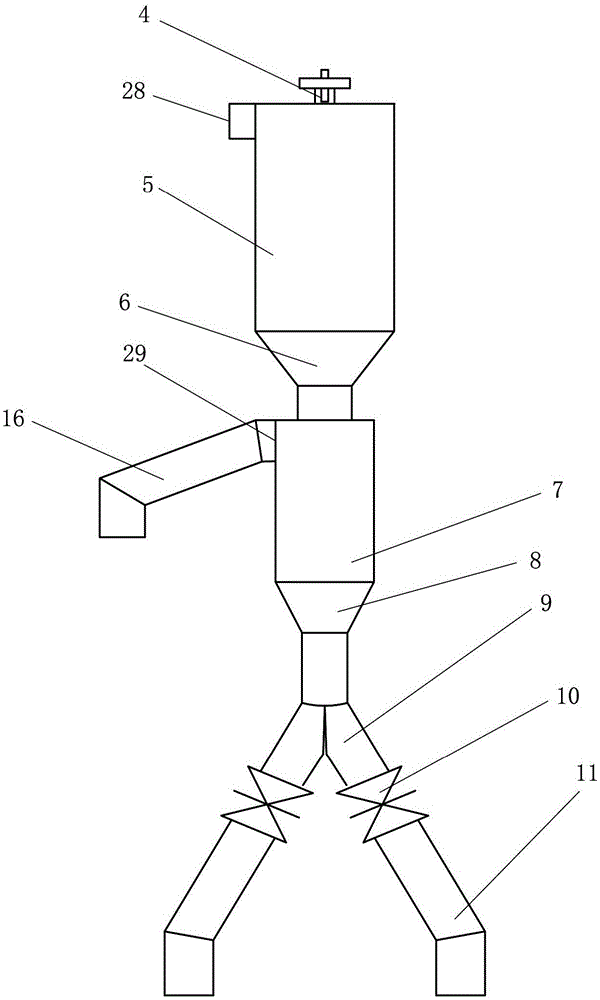

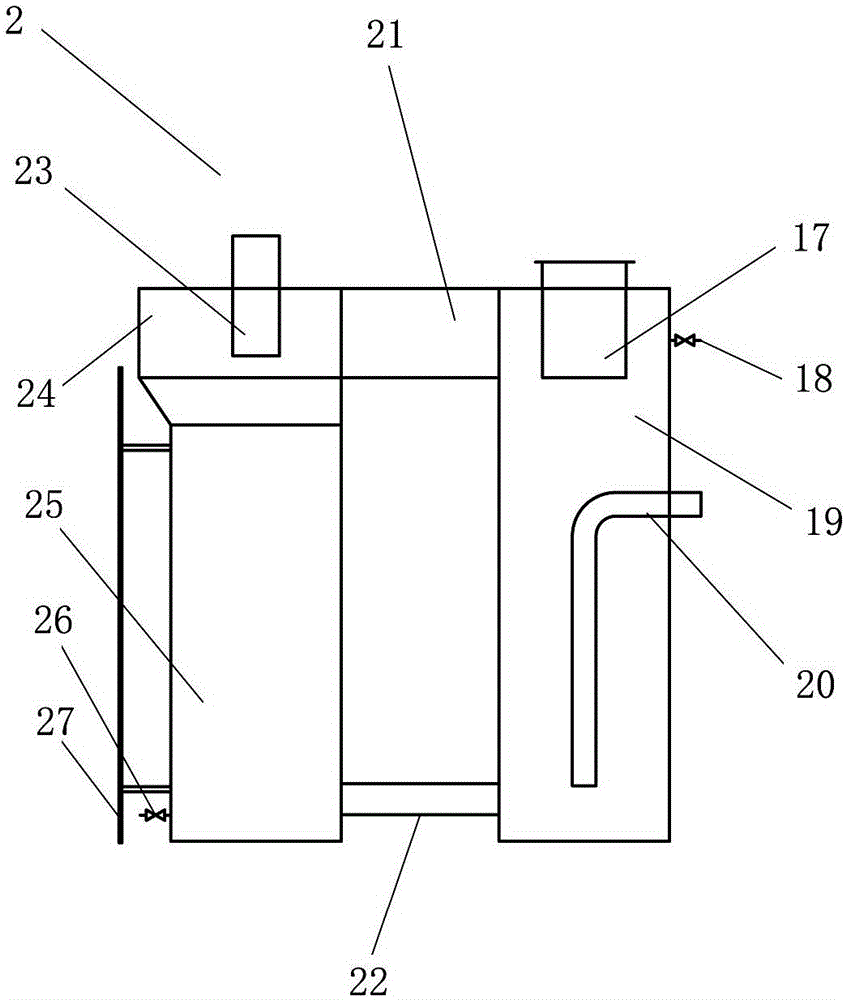

[0016] like Figure 1 to Figure 5 As shown, a high-temperature gas wet dedusting device includes a spray tower 1, an automatic drainage demister 2, and a clarification tank 3. Among them, the spray tower 1 includes a nozzle 4, a cylinder 5, a first conical cylinder 6, an enlarged cylinder 7, a second conical cylinder 8, a tee 9, a valve 10, a connecting pipe 11, an air outlet pipe 16, a dust-containing High temperature gas inlet 28, gas outlet 29 containing water mist. The upper part of the spray tower is a cylinder 5, the opening of the lower end of the cylinder 5 communicates with the first conical cylinder 6 arranged below it, the first conical cylinder 6 communicates with the enlarged cylinder 7, and the dust-laden high-temperature gas inlet 28 Set on the upper side wall of the cylinder 5; the opening of the lower end of the enl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com