Pipe flange protection cover

A technology of pipes and shields, applied in the field of protective shields, can solve the problems of low size adaptability, high production costs, and increased transportation costs, and achieve the effects of reducing production costs, reducing transportation costs, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

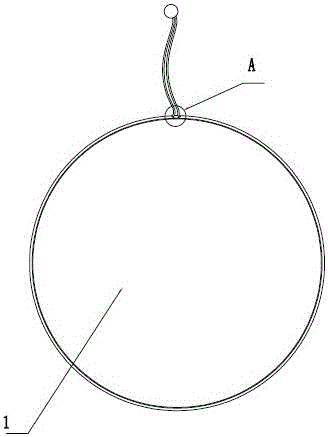

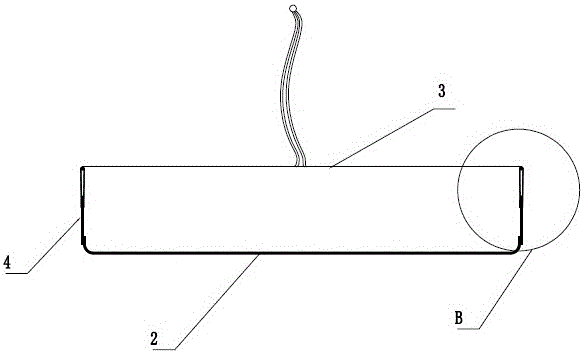

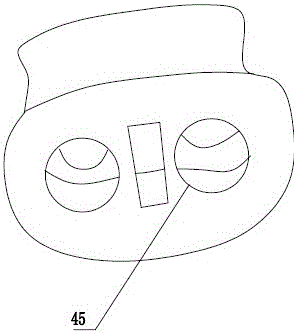

[0021] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 combine Figure 2 to Figure 5 As shown, a pipe flange protection cover includes a cover body 1, the cover body 1 includes a side wall 4 and a bottom surface 2, the inner side of the bottom surface 2 is used to cover the pipe opening, and the side wall 4 includes a lower end 48 and an upper end 49, the lower end 48 is connected to the bottom surface 2, the lower end 48 and the bottom surface 2 are made of polypropylene non-woven fabric or composite leather, and the upper end 49 is made of a soft material and surrounded to form an open end 3; An adjusting member 42 for adjusting the diameter of the opening end 3 is provided on the side wall 4 . The adjustment piece here can be a Velcro that cooperates with each other, or a button, etc., subject to the adjustable diameter of the opening end 3, or even a zipper, the bottom surface is covered on the nozzle, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com