Novel medicinal plastic bottle material and preparation method thereof

A plastic bottle, a new type of technology, applied in the field of special materials for the new type of medicinal plastic bottle body and its preparation, can solve the problems of increasing production costs, increasing the probability of pollution, etc., to reduce the cost of raw materials, facilitate market promotion, and reduce the amount of residue indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

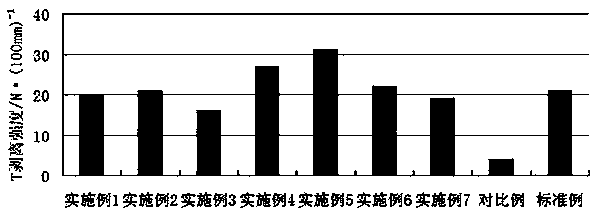

Examples

Embodiment 1

[0024] The preparation method of novel medicinal plastic bottle material of the present invention comprises the steps:

[0025] (1) At an ambient temperature of 20±5°C, weigh 25Kg of high-density polyethylene, 0.125Kg of titanium dioxide, 1Kg of modified nano-magnesium hydroxide and 0.075Kg of zinc stearate, and mix the above raw materials evenly;

[0026] (2) Put the mixture obtained in step (1) into the automatic injection blow molding machine through the feeding machine. After preheating, the raw material is melted in the barrel screw of the injection part, and then passed through the hot runner with high pressure. Inject into the mold cavity to become a parison; at the same time, use high-temperature heat transfer oil to adjust the temperature of the mold; the feeding section of the barrel is 140°C, the middle section of the barrel is 180°C, the front section of the barrel is 195°C, and the hot runner is 210°C; cycle The temperature distribution of the parison controlled b...

Embodiment 2

[0028] The preparation method of novel medicinal plastic bottle material of the present invention comprises the steps:

[0029] (1) At an ambient temperature of 20±5°C, weigh 25Kg of high-density polyethylene, 0.125Kg of titanium dioxide, 0.125Kg of modified nano-magnesium hydroxide and 0.075Kg of zinc stearate, and mix the above raw materials evenly;

[0030] (2) Put the mixture obtained in step (1) into the automatic injection blow molding machine through the feeding machine. After preheating, the raw material is melted in the barrel screw of the injection part, and then passed through the hot runner with high pressure. Inject into the mold cavity to become a parison; at the same time, use high-temperature heat-conducting oil to adjust the temperature of the mold; the feeding section of the barrel is 180°C, the middle section of the barrel is 195°C, the front section of the barrel is 210°C, and the hot runner is 240°C; cycle The temperature distribution of the parison contro...

Embodiment 3

[0032] The preparation method of novel medicinal plastic bottle material of the present invention comprises the steps:

[0033] (1) At an ambient temperature of 20±5°C, weigh 25Kg of high-density polyethylene, 0.125Kg of titanium dioxide, 0.5Kg of modified nano-magnesium hydroxide and 0.075Kg of zinc stearate, and mix the above raw materials evenly;

[0034] (2) Put the mixture obtained in step (1) into the automatic injection blow molding machine through the feeding machine. After preheating, the raw material is melted in the barrel screw of the injection part, and then passed through the hot runner with high pressure. Inject into the mold cavity to become a parison; at the same time, use high-temperature heat-conducting oil to adjust the temperature of the mold; the feeding section of the barrel is 160°C, the middle section of the barrel is 187.5°C, the front section of the barrel is 202.5°C, and the hot runner is 225°C; cycle The temperature distribution of the parison cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com