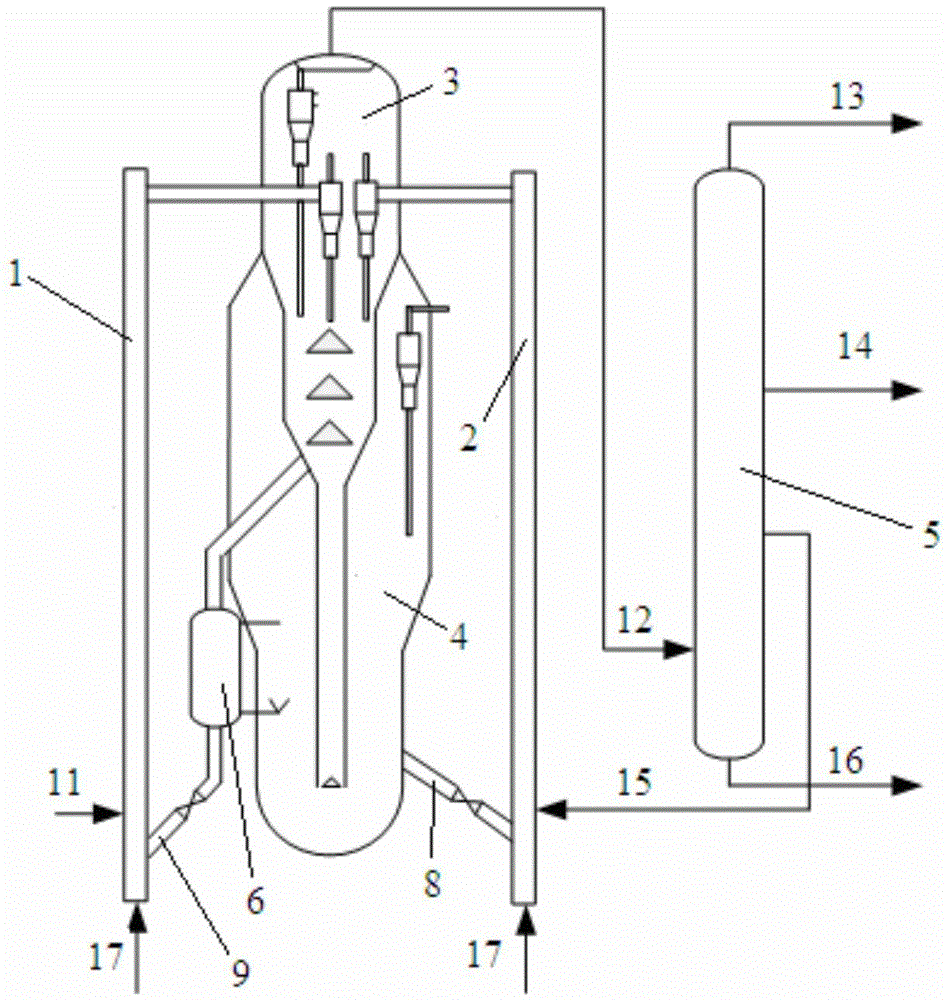

A device and method for fluidized deacidification catalytic cracking of high-acid crude oil

A high-acid crude oil, catalytic cracking technology, used in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of large activity drop, loss of straight-run diesel fraction, no special requirements, etc., to reduce rapid deactivation, strengthen catalytic cracking, The effect of increasing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

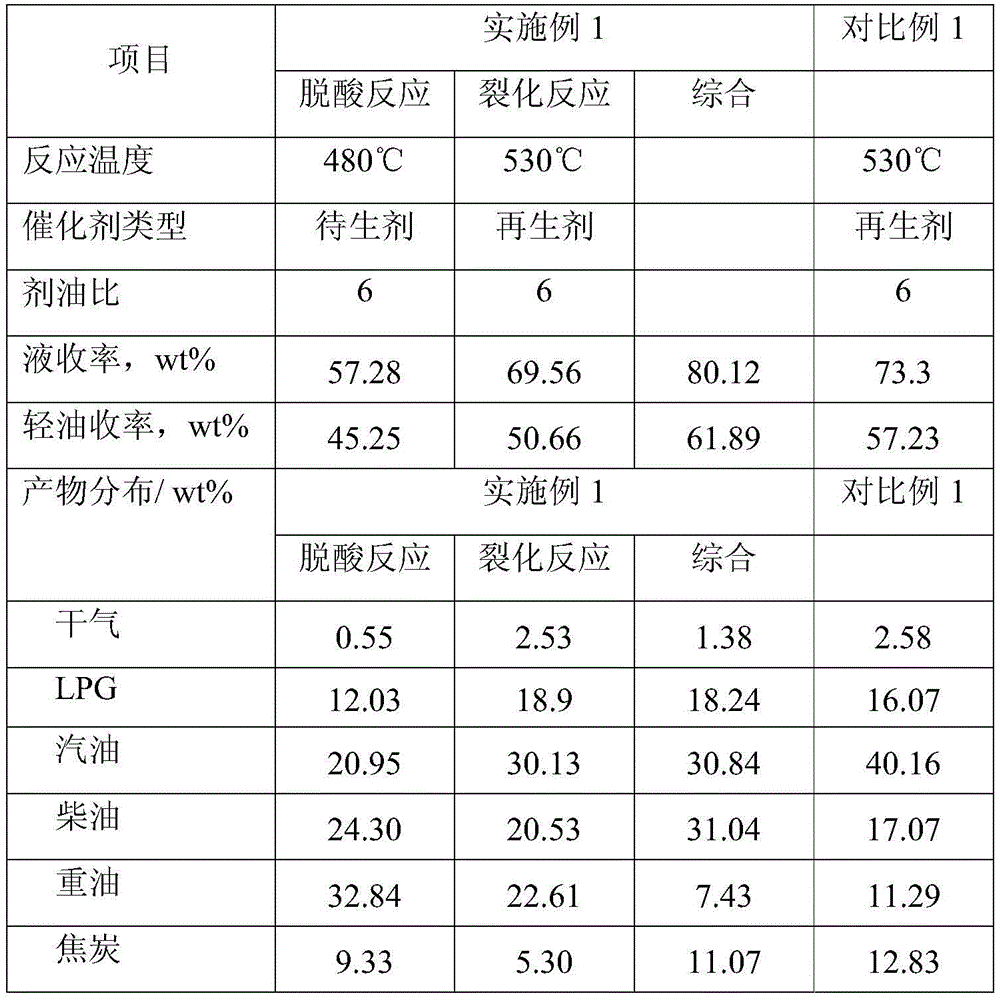

[0051] In the following examples, the above-mentioned device and method of the present invention are used to perform deacidification and catalytic cracking of high-acid crude oil.

[0052] Example 1 uses Sudandar high-acid crude oil as raw material, and LVR-60R balancer as catalyst. Dargao acid crude oil enters the first riser reactor to react with the raw catalyst for deacidification and carbon removal. The reaction temperature is 480°C, the carbon content of the raw catalyst is 1.43wt%, and the temperature is 530°C. After separation, the liquid products after the reaction are separated into gasoline and diesel oil, and the fraction above 350°C (heavy oil) enters the second riser reactor to react with the catalyst from the catalyst regenerator, the reaction temperature is 530°C, and the carbon content of the regenerant is 0.06wt %.

[0053] See Table 1 and Table 2 for the properties of the raw material high-acid crude oil and the catalyst in this example. See Table 3 for ot...

Embodiment 2

[0062] In the following examples, the above-mentioned device and method of the present invention are used to perform deacidification and catalytic cracking of high-acid crude oil.

[0063] In this example, Sudandar high-acid crude oil is used as the raw material, and the LVR-60R balancer is used as the catalyst. Dargao acid crude oil enters the first riser reactor to react with the raw catalyst for deacidification and carbon removal. The reaction temperature is 480°C, and the carbon content of the raw catalyst is 1.25wt%. After separation, the liquid products after the reaction are separated into gasoline and diesel oil, and the fraction above 350°C (heavy oil) enters the second riser reactor to react with the catalyst from the catalyst regenerator. The reaction temperature is 560°C, and the carbon content of the regenerated catalyst is 0.06wt %.

[0064] See Table 1 and Table 2 for the properties of the raw material high-acid crude oil and the catalyst in this example.

Embodiment 3

[0066] In the following examples, the above-mentioned device and method of the present invention are used to perform deacidification and catalytic cracking of high-acid crude oil.

[0067] In this example, Sudandar high-acid crude oil is used as the raw material, and the LVR-60R balancer is used as the catalyst. Dargao acid crude oil enters the first riser reactor to react with the raw catalyst for deacidification and carbon removal. The reaction temperature is 430°C, and the carbon content of the raw catalyst is 1.43wt%. After separation, the liquid products after the reaction are separated into gasoline and diesel oil, and the fraction above 350°C (heavy oil) enters the second riser reactor to react with the catalyst from the catalyst regenerator. The reaction temperature is 550°C, and the carbon content of the regenerated catalyst is 0.06wt %.

[0068] See Table 1 and Table 2 for the properties of the raw material high-acid crude oil and the catalyst in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com