A prefabricated monolithic concrete shear wall panel with openings at the bottom and multiple connecting beams

A concrete shear wall and prefabricated concrete technology, which is applied to walls, building components, and earthquake resistance, can solve problems such as the large number of steel joints, the difficulty of post-earthquake repair, and the difficulty in ensuring quality, so as to achieve high construction efficiency and reduce hidden dangers in connection , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

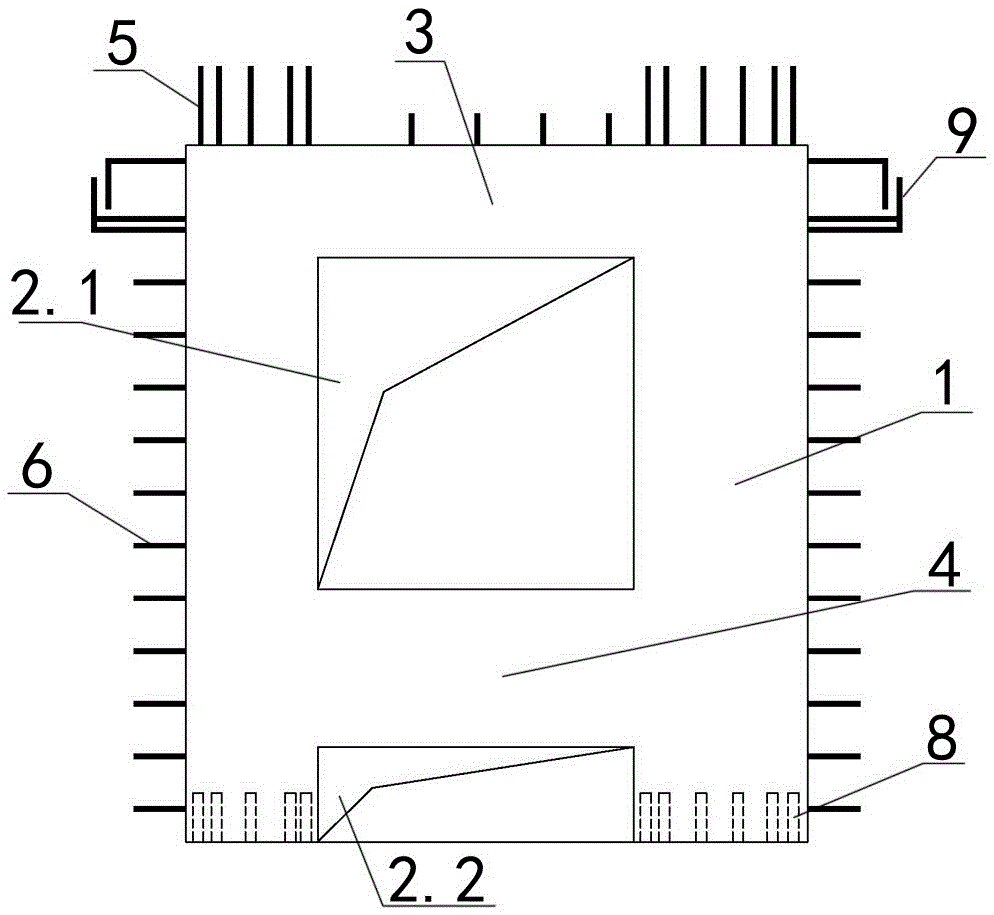

[0045] Embodiment one: see figure 1 as shown,

[0046] A new type of prefabricated integral concrete shear wall panel with holes at the bottom and multi-connected beams, including the lateral connecting reinforcement 6 of the precast concrete shear wall panel, the top connecting reinforcement 5, and the bottom installation corresponding to the top connecting reinforcement 5 The sleeve 8, at least one row of window openings 2.1 in the middle of the wall panel, and the two sides of the window opening 2.1 respectively form the wall limb 1 of the shear wall panel, the upper side of the window opening 2.1, and the two adjacent wall limbs 1 The top end is connected to form a common connecting beam 3, which also includes:

[0047] The lower end of the wall panel is provided with a structural opening 2.2 corresponding to the window opening 2.1, and an energy-dissipating connecting beam A4 is formed between the structural opening 2.2 and the window opening 2.1.

[0048] The window op...

Embodiment 2

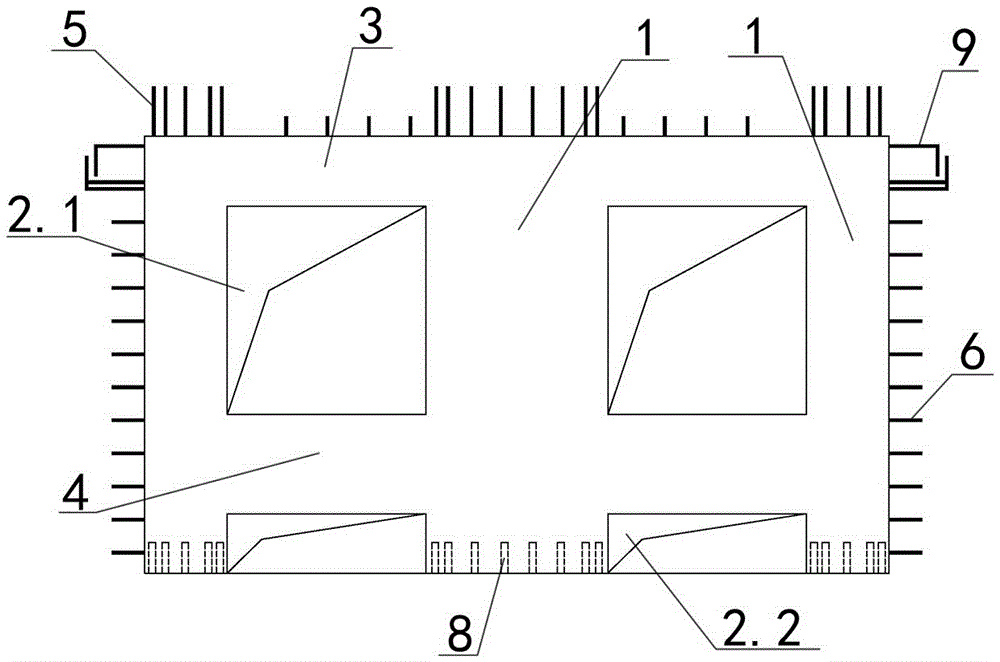

[0051] Embodiment two: see figure 2 As shown, the difference from the first embodiment is that the prefabricated concrete shear wall panel is a three-leg shear wall, and there are two rows of window openings 2.1 and structural openings 2.2.

Embodiment 3

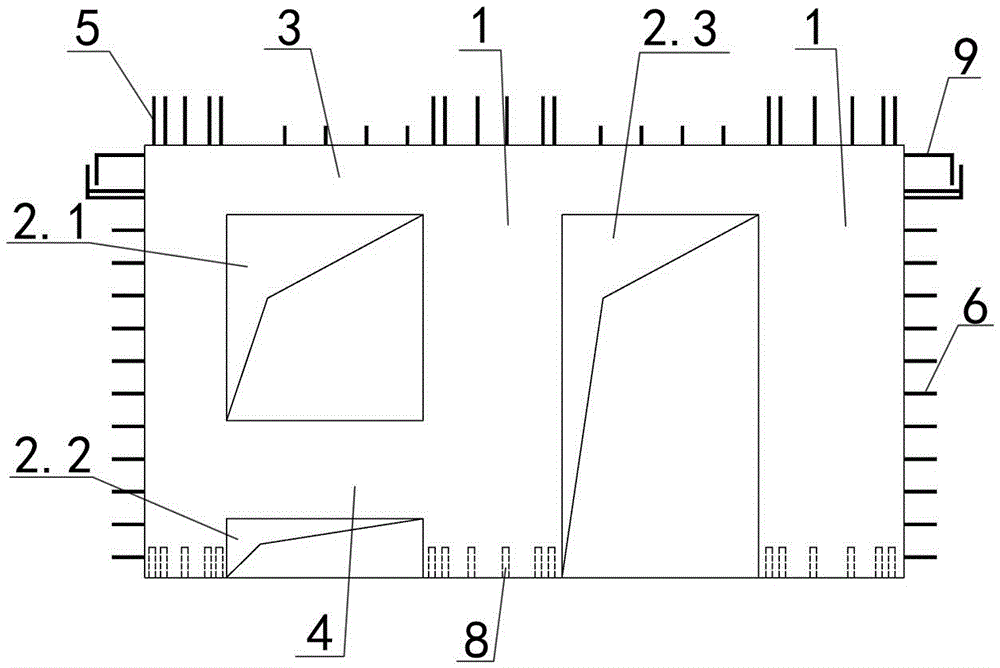

[0052] Embodiment three: see image 3 As shown, the difference from Example 1 is that the precast concrete shear wall panel is a three-leg shear wall, and there is a door opening 2.3 on the wall foot 1, and the upper side of the door opening 2.3 is also a common connecting beam 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com