Novel total-reverse-flow rotary non-mixing heat exchanger

A flow channel converter and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, moving tube heat exchangers, etc., can solve the problem of increasing fluid turbulence in the shell side of tube-and-tube heat exchangers, etc. problem, to achieve the effect of fluid temperature homogenization, increase the average temperature difference of heat transfer, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

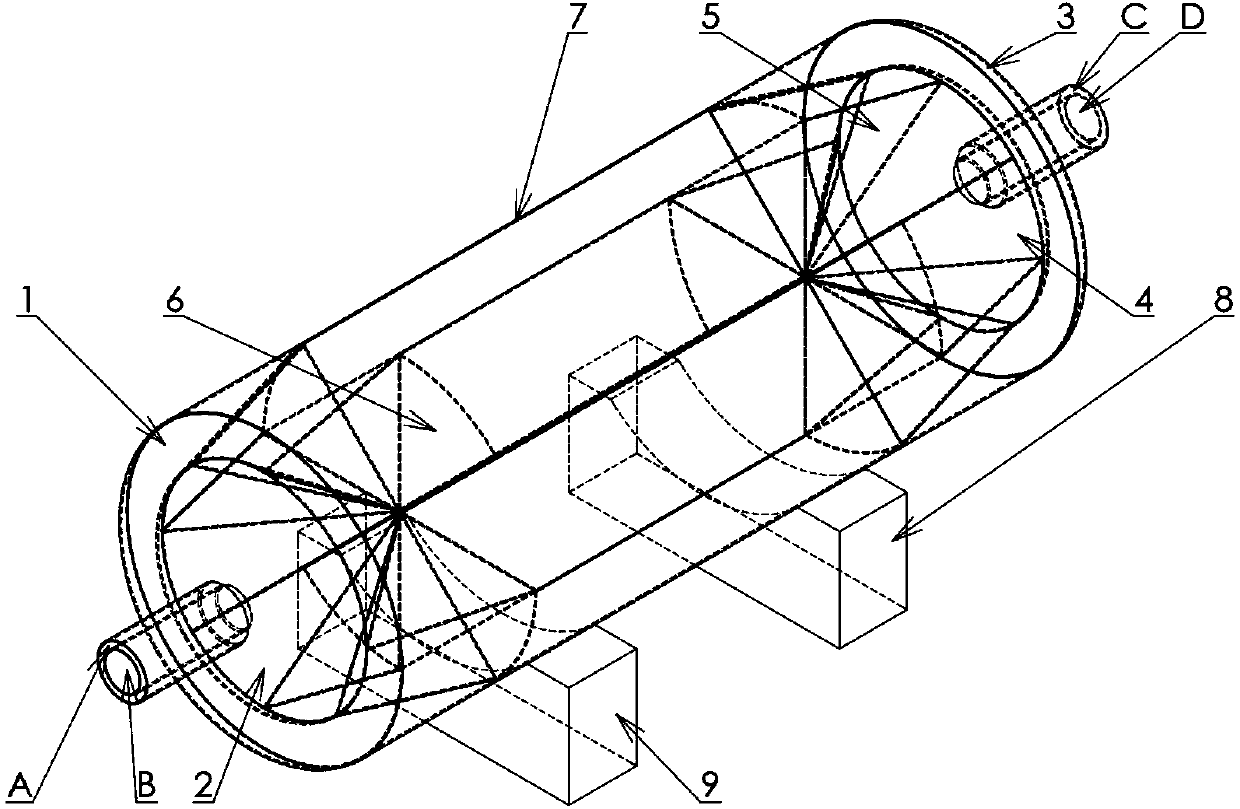

[0032] The main body length of the fully countercurrent rotating non-mixing heat exchanger is 1m, and the diameter is 0.4m, of which the length of the heat exchanger cylinder partition is 0.8 meters, the flow channel exchanger length is 0.1 meters, and the heat exchanger cylinder partition The number of plates and partitions for each runner converter is 8, and the number of outer baffles and inner baffles for each runner converter is 4. The original thickness is 1mm and the material is stainless steel. The cross-sectional diameter on the left side of the runner converter is 0.3m. The experimental medium is air, the flow rate of cold air is 11.3 cubic meters per second, the inlet temperature is 300K, the flow rate of hot air is 11.3 cubic meters per second, and the inlet temperature is 800K. Use Fluent fluid mechanics calculation software to simulate heat transfer calculation. The heat transfer effect obtained is compared with the tube heat exchanger under the same heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com