An ultra-thin mesh self-oscillating heat pipe cooling film and its processing method

A processing method and heat dissipation film technology, which are applied in the field of ultra-thin mesh self-oscillating heat pipe heat dissipation film and its processing, can solve the problems of heat pipes that cannot be made too thin, easy to be damaged by stamping, and cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

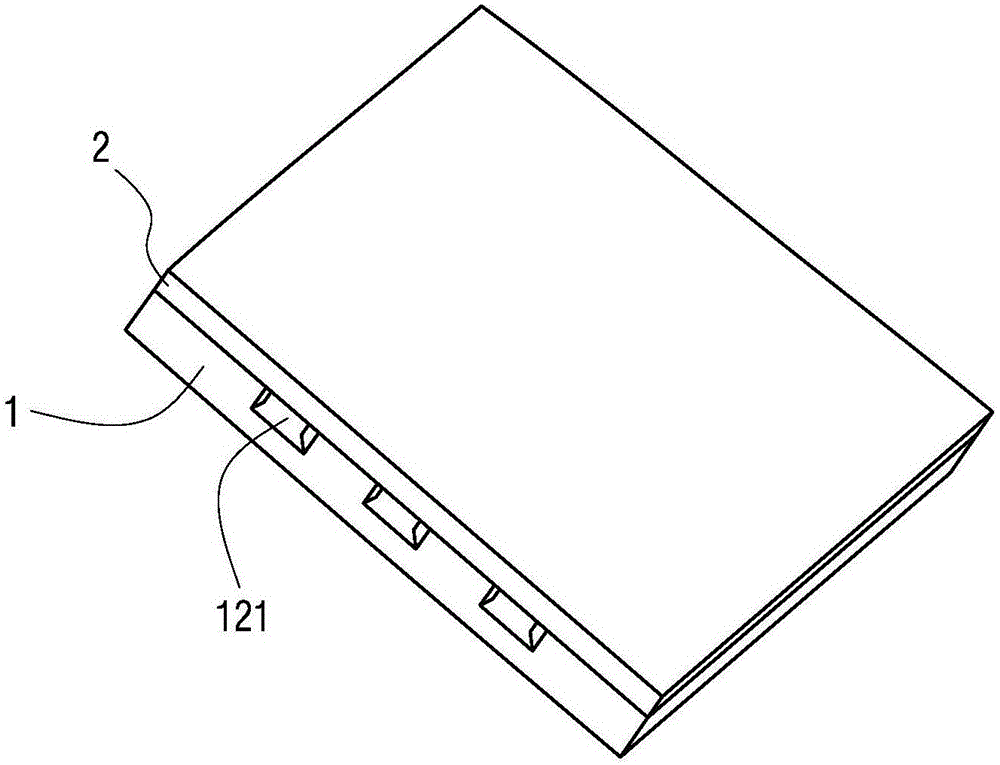

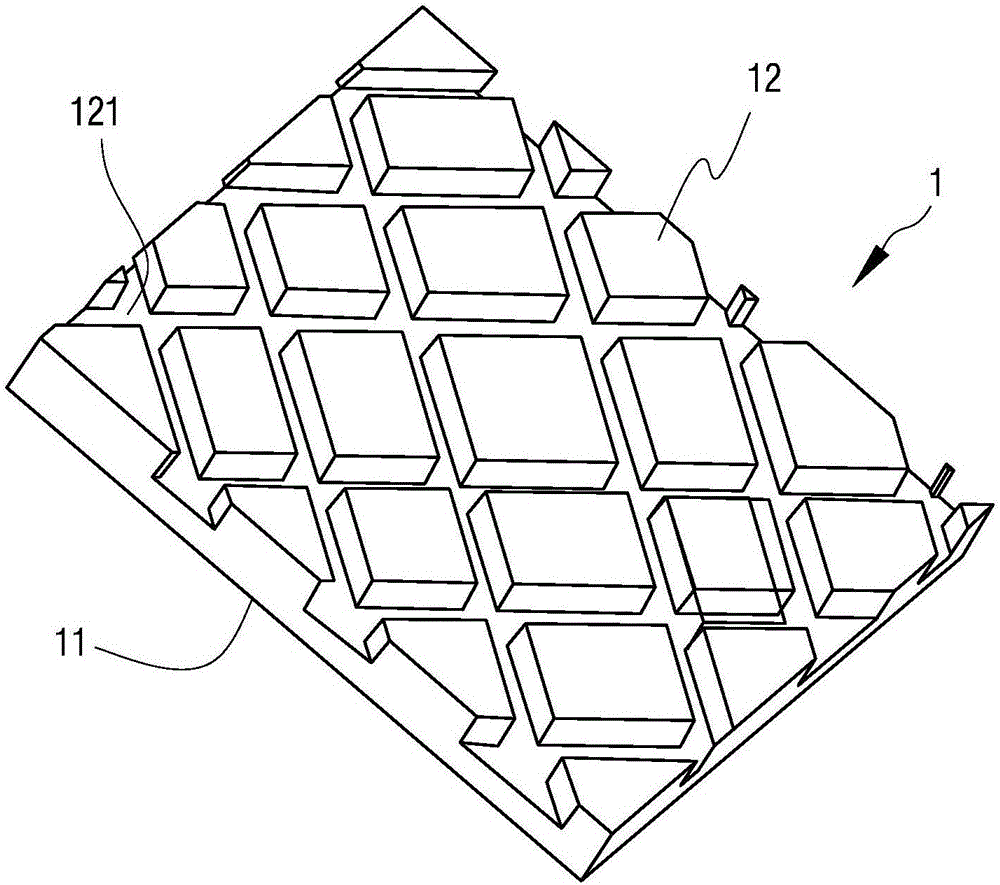

[0016] figure 1 Shown is a schematic structural view of an ultra-thin reticulated self-oscillating heat pipe heat dissipation film according to the present invention. Heat dissipation film, the heat dissipation film of this ultra-thin structure can be used for heat dissipation of small devices such as mobile phones. The existing heat dissipation film structure can only be as thin as 0.45mm, and most of them use a single channel for heat dissipation, mainly for a single specific heat source to dissipate heat, so it is impossible to make an ultra-thin heat dissipation film with a large area.

[0017] As shown in the figure, the heat dissipating film is formed by stacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com