Method for predicting aging failure rule and service life of polymer material under multiple environmental factors

A polymer material and prediction method technology, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve problems such as insufficient reliability of life prediction, change of aging mechanism, linear deviation of Arrhenius curve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

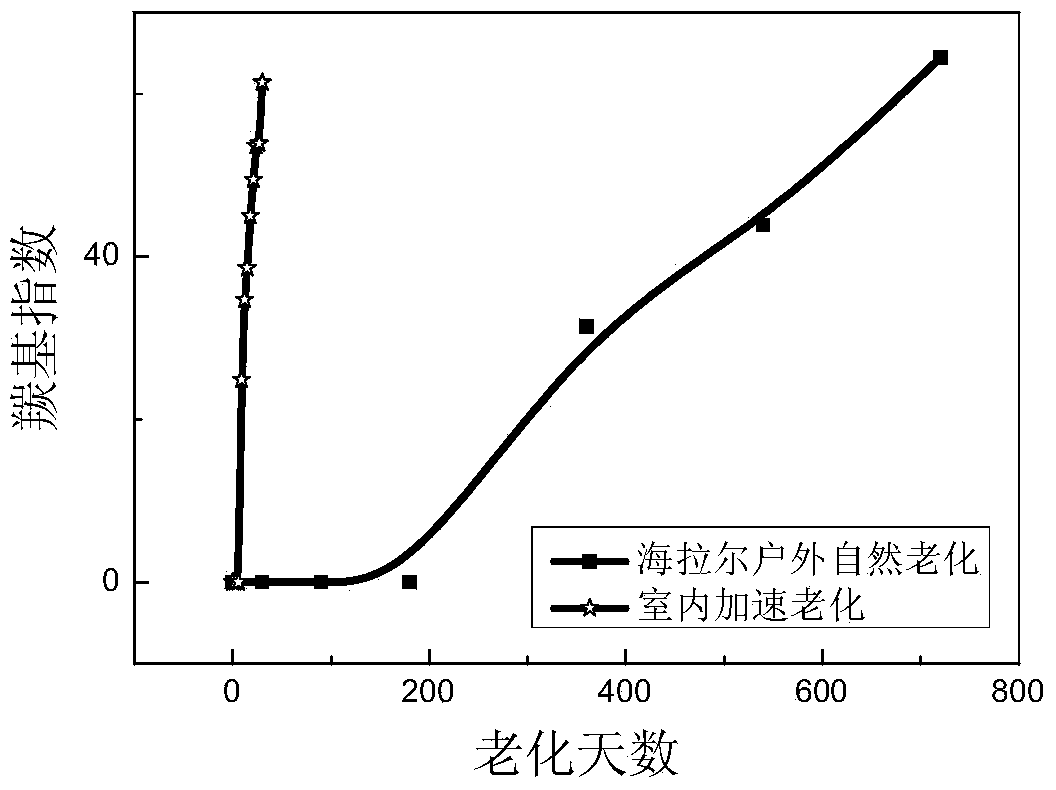

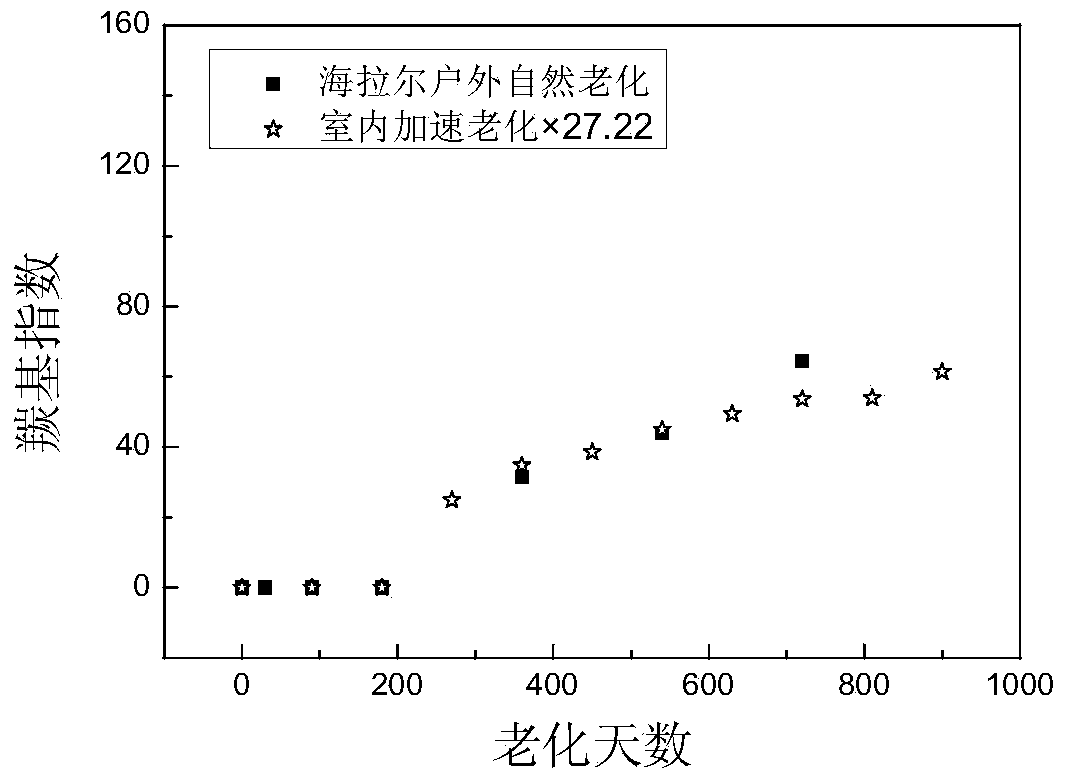

[0054] Example 1 Prediction method of outdoor aging failure law of polymer material Hailaer under the condition of multiple environmental factors

[0055] Polypropylene (T30s, Dushanzi Petrochemical) was used as the polymer material, and then a dumbbell-shaped specimen conforming to the ASTM tensile test standard was further prepared by injection molding.

[0056] Use the xenon lamp aging test box (CI 3000+, Atlas) to prepare the dumbbell-shaped sample. The temperature of the test box is 55±0.5°C, the temperature of the blackboard is 70±0.5°C, the relative humidity is 65±5%, and the irradiance is 0.55 W / m 2 / nm (at 340nm), 102min drying plus 18min deionized water spray cycle conditions for accelerated aging test (GB / T 16422.2-1999 / ISO4892-2:1994).

[0057] The outdoor aging experiment in Hailaer was carried out on polypropylene tensile splines. The polypropylene tensile splines were placed on an aging exposure frame facing south at a 45° angle, and the two ends of the splines...

Embodiment 2

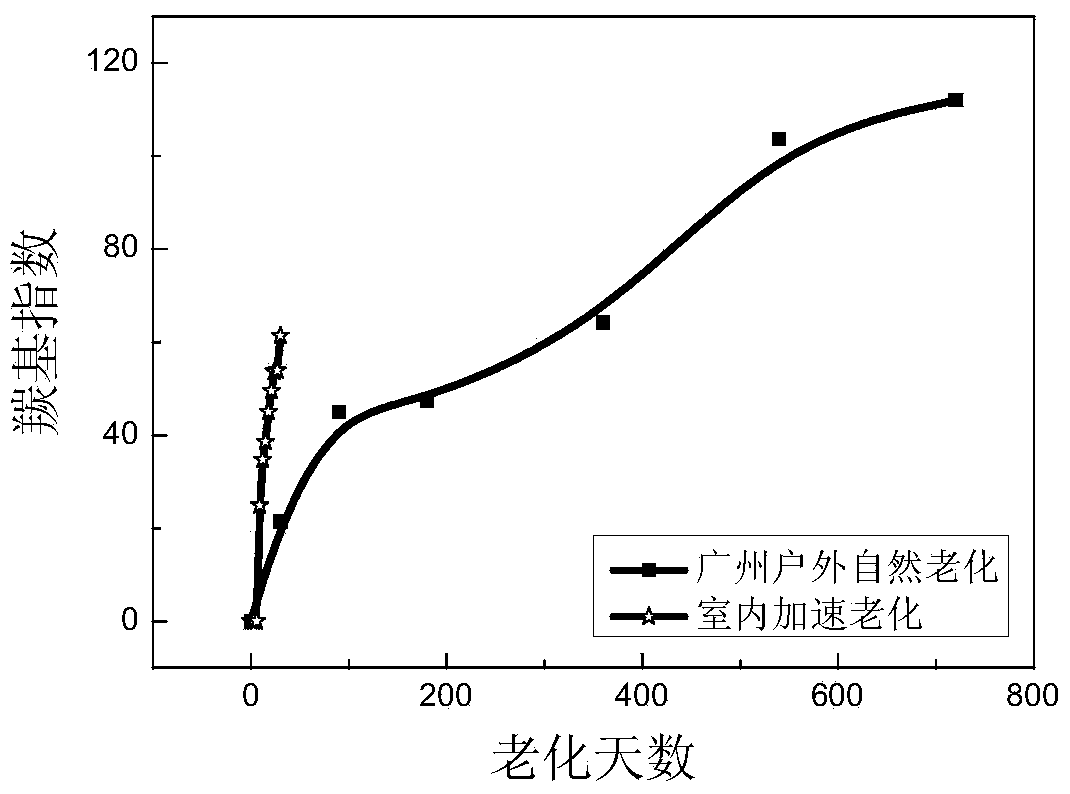

[0062] Example 2 Prediction method of polymer material Guangzhou outdoor aging failure law under multiple environmental factors

[0063] Polypropylene (T30s, Dushanzi Petrochemical) was used as the polymer material, and then a dumbbell-shaped specimen conforming to the ASTM tensile test standard was further prepared by injection molding.

[0064] Use the xenon lamp aging test box (CI 3000+, Atlas) to prepare the dumbbell-shaped sample. The temperature of the test box is 55±0.5°C, the temperature of the blackboard is 70±0.5°C, the relative humidity is 65±5%, and the irradiance is 0.55 W / m 2 / nm (at 340nm), 102min drying plus 18min deionized water spray cycle conditions for accelerated aging test (GB / T 16422.2-1999 / ISO4892-2:1994).

[0065] An outdoor aging experiment was carried out in Guangzhou on polypropylene tensile splines. The polypropylene tensile splines were placed on an aging exposure frame facing south at a 45° angle, and the two ends of the splines were clamped by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com