Mine working face top board and bottom board mining breaking fracture development dynamic monitoring method

A technology of dynamic monitoring and mining damage, applied in geophysical measurement, instruments, etc., can solve the problem of unable to dynamically present mining fracture development form, mining fracture shape, dynamic evolution cannot be realized, and hinder thick coal seam water conduction fracture zone Detection and other problems, to achieve the effect of convenient underground construction, solving limitations, and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

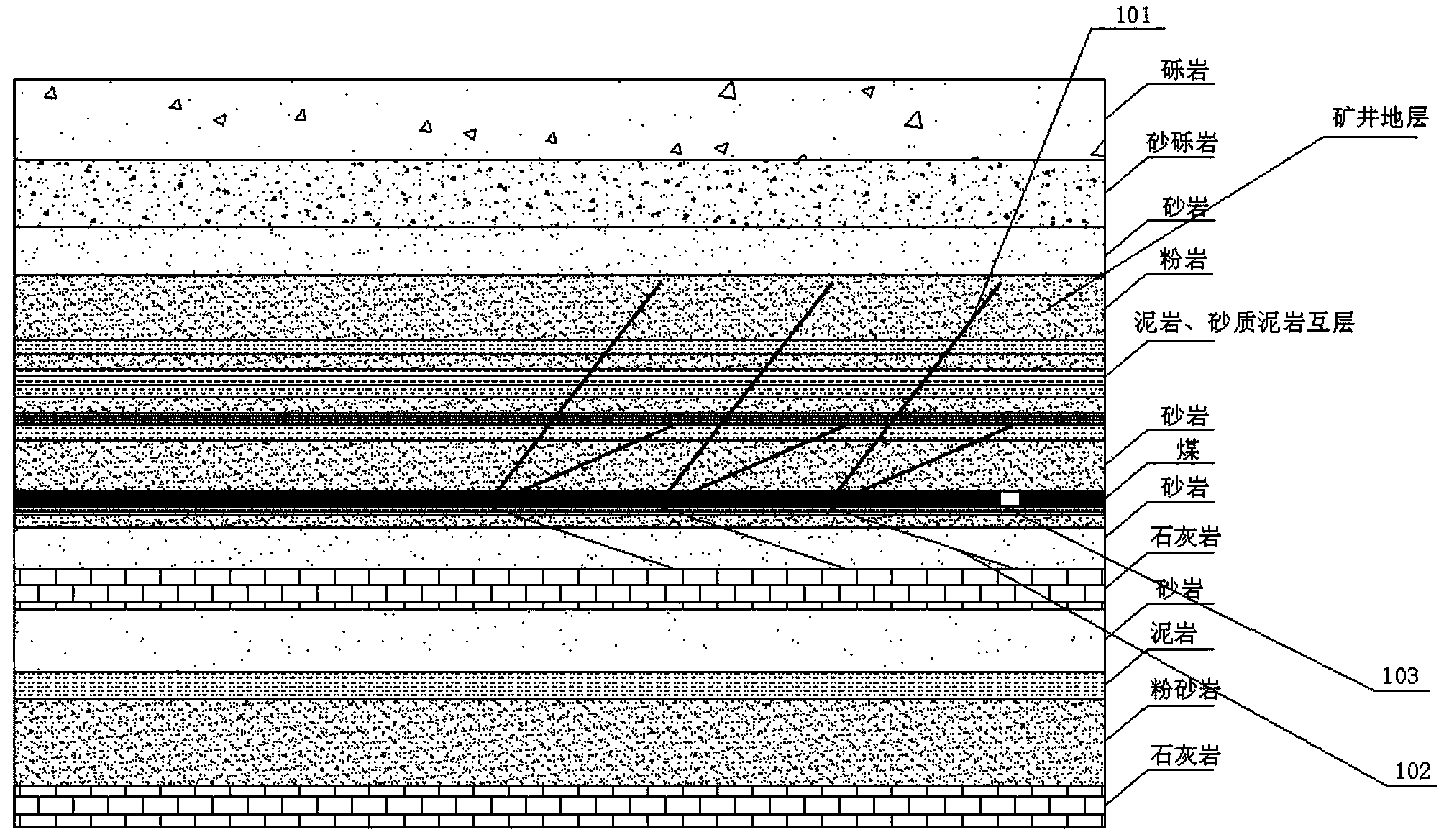

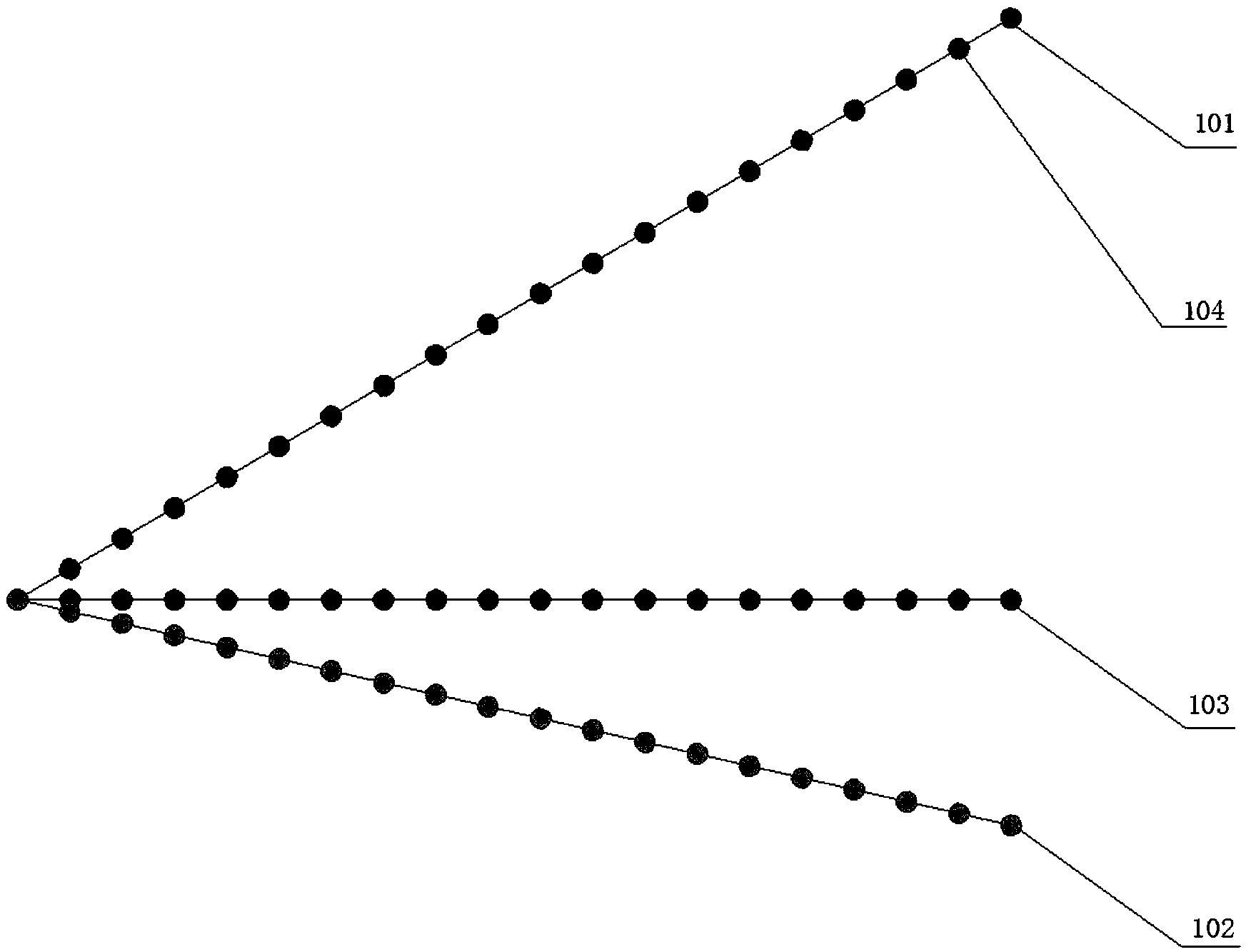

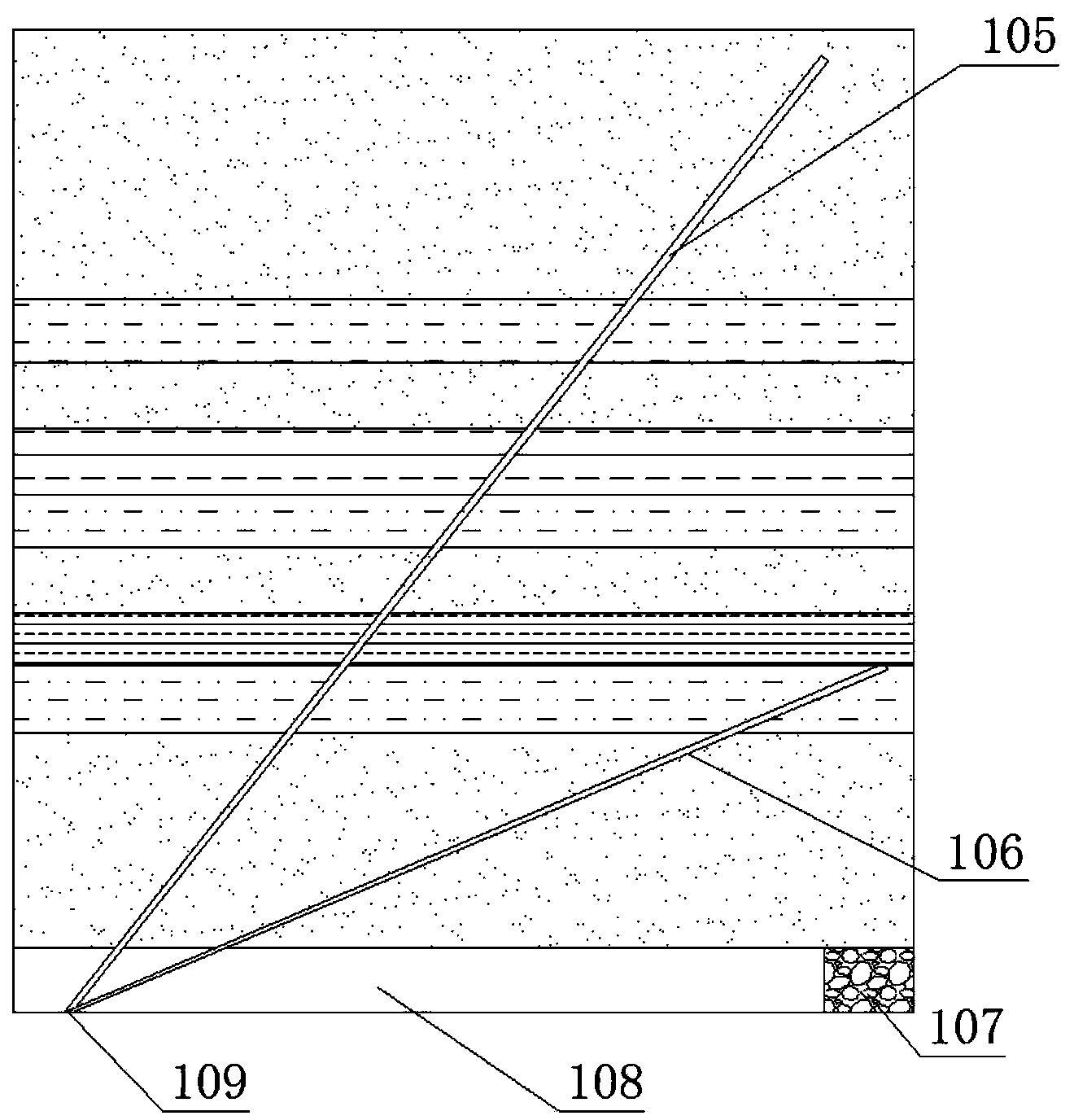

[0024] This embodiment mainly includes numerical simulation of mining surrounding rock in a mine working face, design and construction of drilling holes for dynamic monitoring of mining cracks in the roof and floor of a mine working face, dynamic acquisition of electrical data of monitoring holes, establishment of geophysical models, and forward and inverse data analysis. Five steps for analysis of cracks in the roof and floor of coal mining face:

[0025] (1) Numerical simulation of surrounding rock in mining face

[0026] As the current working faces are all mining technologies such as large mining thickness, large span, and fully mechanized caving technology, the past mining crack development mechanism cannot estimate the development range of mining cracks and the elastoplastic area of mining surrounding rock. Therefore, the use of mine Triaxial rock mechanics tests are carried out for cores of previous exploration holes, and numerical simulation calculations are carried out b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com