Olive cuttage seedling cultivating cuttage bed and cuttage seedling cultivating method

A technology for growing seedlings by cuttings and olives, which is applied in the field of cuttings and seedlings of olives, which can solve the problems of complex management and high cost of seedlings, and achieve the effect of good root development and high survival rate of transplanting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

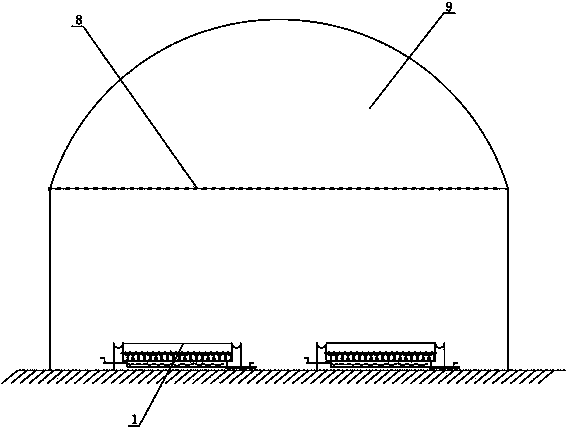

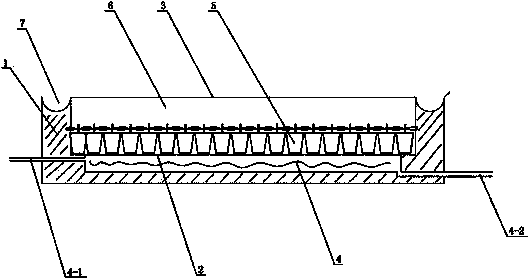

[0022] Embodiment 1, as figure 1 , 2 As shown, in May 2014, a large-scale cutting seedling repeat experiment was carried out in the plastic greenhouse 9 of Haikou Forest Farm, Kunming City. A raised bed was used as a transplanting bed. The height of the raised bed was 0.3m, and the width of the bed was 1.2m. The U-shaped tank bed 1 is made of bricks, which can retain water for a long time. The bottom of the water storage tank 4 is slightly higher than the ground, which is convenient for installing the water outlet pipe 4-2 and the water inlet pipe 4-1. The depth of the water storage tank 4 is about 6cm. shape seedling-raising container support 2, place seedling-raising container 5 above, lay plastic film support 3 apart from the place of 5~10cm above the seedling-raising container mouth, lay plastic film above, the place of 2m above U-shaped sink type groove bed 1 builds shade net 8 (70 % sunshade net), cutting seedling raising steps:

[0023] Step 1, preparation of cutting...

Embodiment 2

[0031] Example 2. In June 2014, a large-scale cutting seedling repeat experiment was carried out in the plastic greenhouse of Haikou Forest Farm, Kunming City. The design of the low bed was adopted, and the structure was the same as that of the high bed. The difference was that the slotting bed was built below the ground and the edge of the water storage tank was slightly higher. On the ground, so that the plastic film is compacted, the cutting step is identical with embodiment 1.

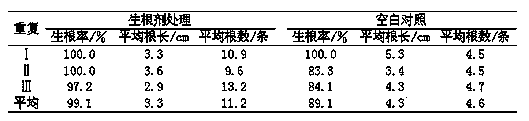

[0032] Cutting results were grouped and counted, the results are shown in Table 1:

[0033] Table 1 Rooting results of cuttings

[0034]

[0035] It can be seen from the table that the rooting rate of cuttings with this technology can reach 100% at 50 days, with an average of 99.1%. The rooting rate without any rooting agent treatment can also be as high as 100%, with an average of 89.1%. In terms of rooting quality, the number of adventitious roots can be significantly increased after treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com