Electromechanical-hydraulic composite brake device of hub motor type heavy-duty vehicle

A compound braking and wheel hub motor technology, applied in the direction of mechanical braking transmission, braking transmission, liquid resistance brakes, etc., can solve the problems of slow braking torque not independently adjustable, difficult assembly, large volume, etc., to achieve Compact structure, good heat dissipation effect, and the effect of eliminating air loss and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

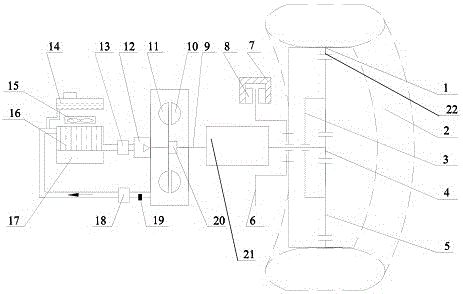

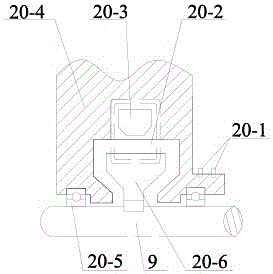

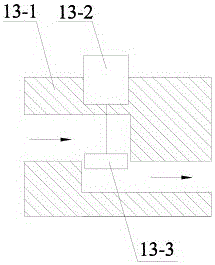

[0025] Such as Figure 1~4 As shown, an electromechanical-hydraulic composite brake device of hub motor type heavy-duty vehicle includes a planetary gear train, a friction brake, a motor 21 and a hydraulic retarder, and the planetary gear train includes a planetary carrier 3, a sun gear 4, and a ring gear 22 and a plurality of planetary gears 5, the planetary gears 5 are arranged between the sun gear 4 and the ring gear 22, and mesh with the sun gear 4 and the ring gear 22 respectively, the ring gear 22 is fixedly connected with the hub 1, and the planetary gears 5 are also installed on On the planet carrier 3, the planet carrier 3 is fixed, and the friction brake includes a brake caliper body 7, a friction block group 8 and a brake disc 6, the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com