A functional fresh rice flour packaging bag

A technology for packaging bags and fresh rice noodles, applied in the directions of packaging, transportation and packaging, special packaging objects, etc., can solve the problems of difficult control of moisture content, high cost consumption, improper operation, etc., and achieves protection of toughness and elasticity. The cost of working hours and the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the following examples in conjunction with the accompanying drawings.

[0012] Example.

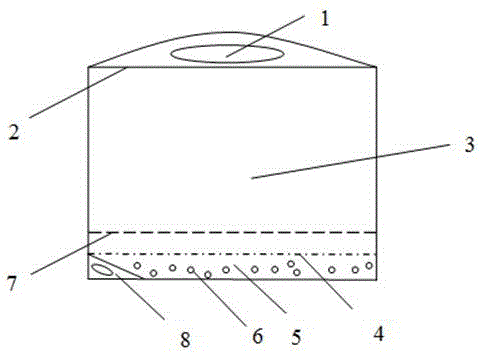

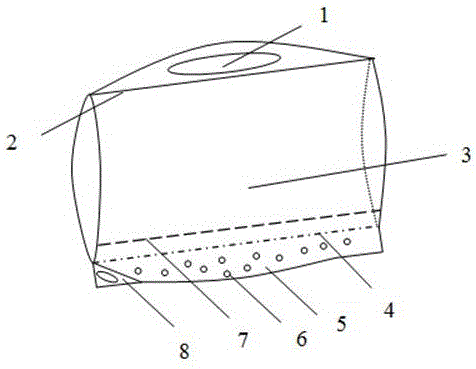

[0013] Such as figure 1 As shown, a functional fresh rice noodle packaging bag is composed of a packaging bag carrying hole 1, a packaging bag upper seal 2, a packaging bag body 3, a breakpoint line 4, a bottom water control area 5, a hole 6, and a pre-drawn vacuum edge sealing line 7 And the bottom carries hole 8 to form. The upper part of the packaging bag body 3 is provided with a packaging bag upper seal 2, and the packaging bag upper seal 2 is provided with a packaging bag carrying hole 1; the lower part of the packaging bag body 3 is provided with a bottom water control area 5, and several holes are arranged on the bottom water control area 5 6. The bottom water control area 5 is connected with the packaging bag body 3 by a breakpoint line 4, and there is a pre-drawn vacuum sealing line 7 above the breakpoint line 4; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com