Integrated aerobic granular sludge compound purifier and method for treating sewage

A technology of aerobic granular sludge and purifier, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of low biomass, low treatment efficiency and small population. and other problems to achieve high biological activity, improve work efficiency, and increase the speed of biochemical reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

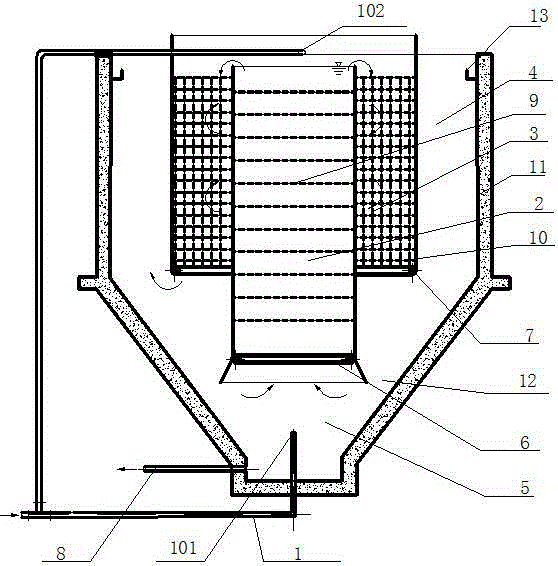

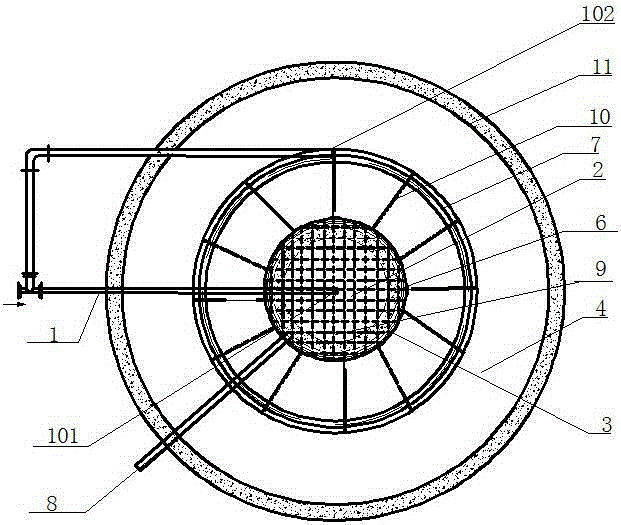

[0024] Examples of purifiers are figure 1 and figure 2 Shown: an integrated aerobic granular sludge composite purifier, including a water inlet pipe 1, a sludge discharge pipe 8, the composite purifier also includes a casing 11, and the casing 11 is provided with a central reaction cylinder 2, a descending The swirl ring 3, the shell 11, the central reaction cylinder 2 and the descending swirl ring 3 are all circular and have the same geometric center. The horizontal screen plate 9 of the reaction cylinder is arranged horizontally, the first annular microporous aeration tube 6 is arranged on the lower edge of the central reaction cylinder 2, and a plurality of swirl rings vertically arranged in the radial direction are arranged in the descending swirl ring 3 The vertical mesh plate 10, the second annular microporous aeration pipe 7 is arranged on the lower edge of the descending swirl ring 3, the side wall sedimentation water outlet area 4 is arranged between the descending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com