Device and process for preparing chalcogenide infrared glass material and method of device

An infrared glass and chalcogenide technology, applied in glass furnace equipment, glass manufacturing equipment, glass production, etc., can solve the problems of glass liquid surface disturbance, increase the damage rate of optical components, reduce the imaging quality of optical systems, etc., and achieve reduction Streaks, effects that improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

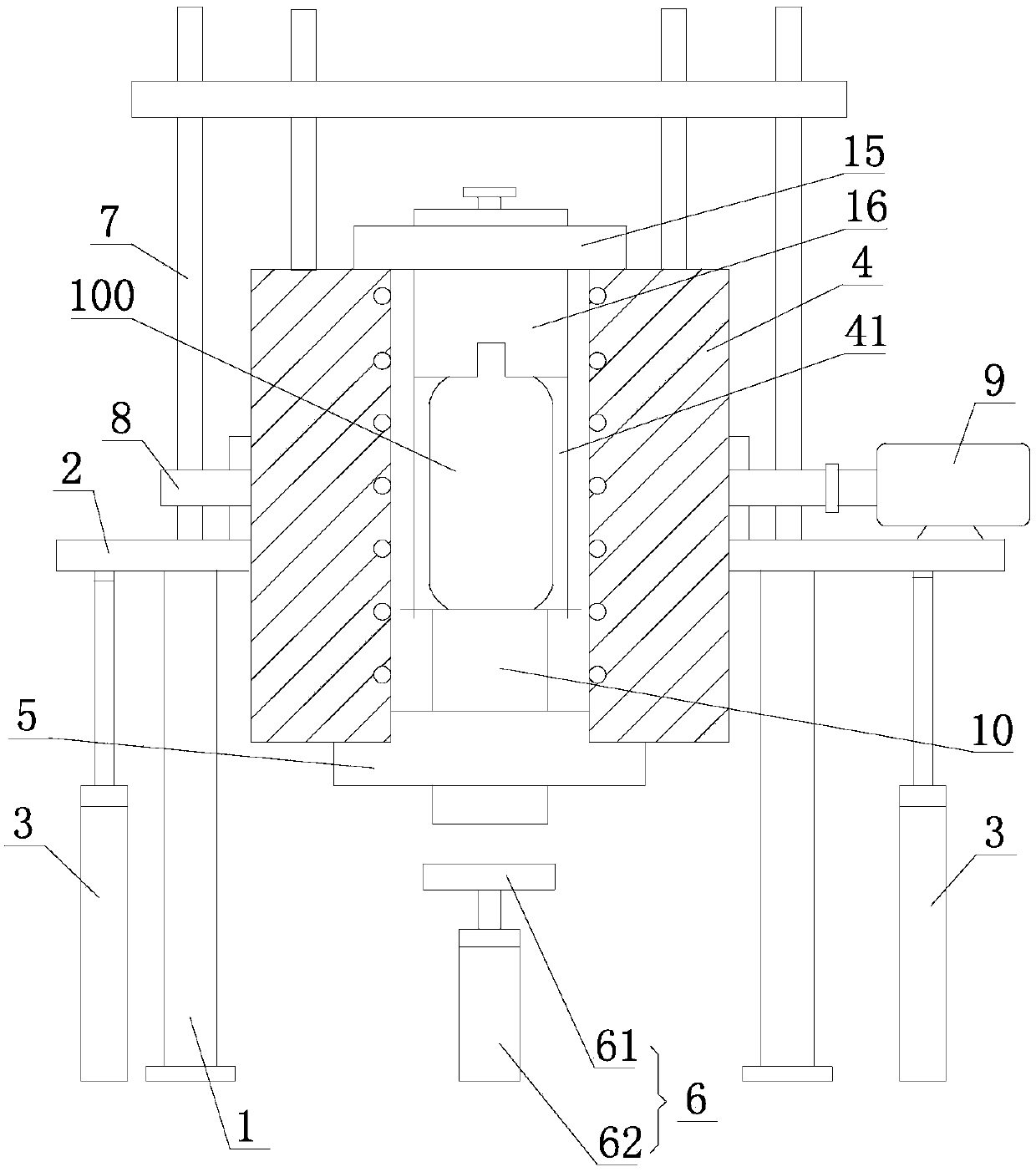

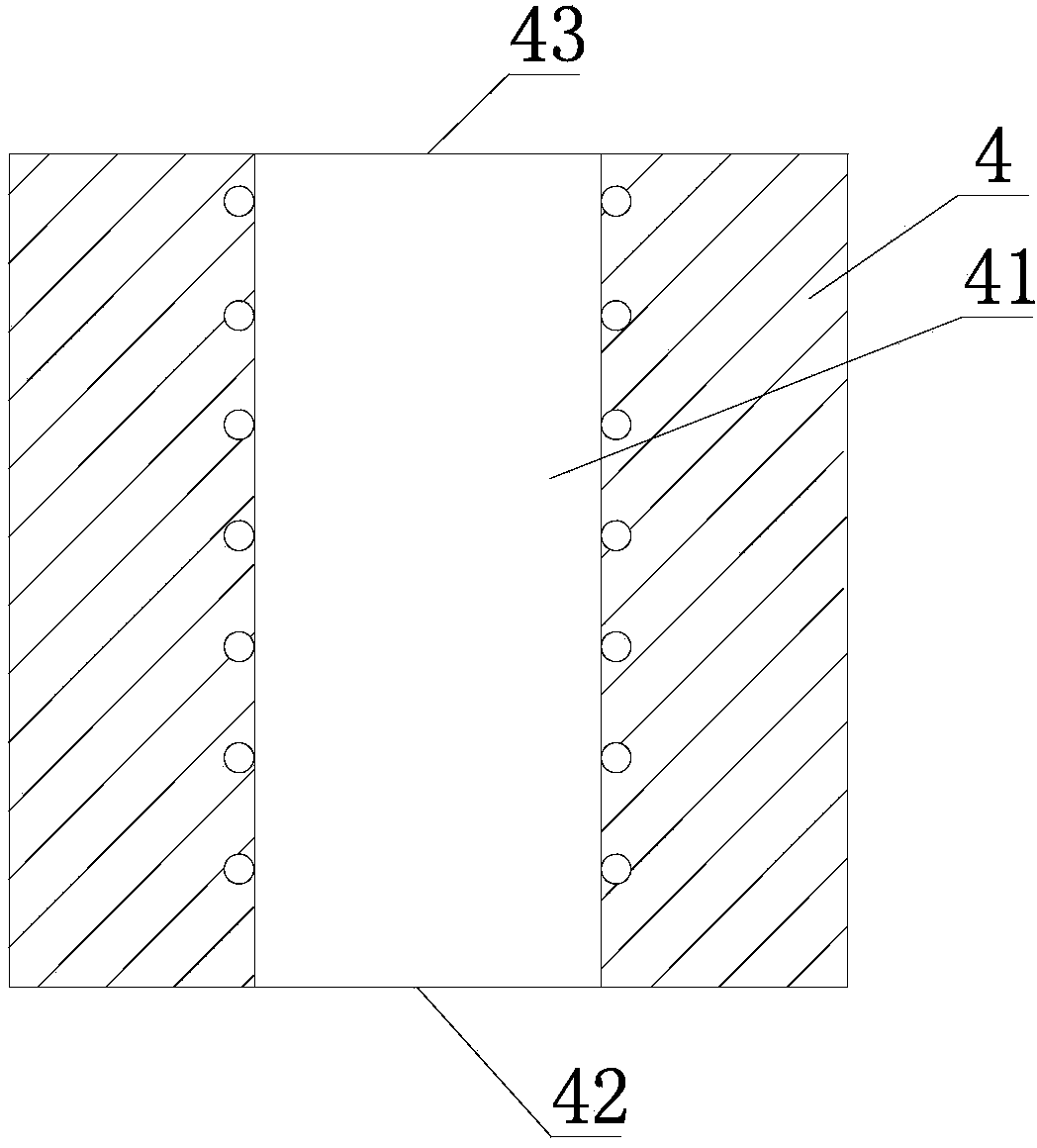

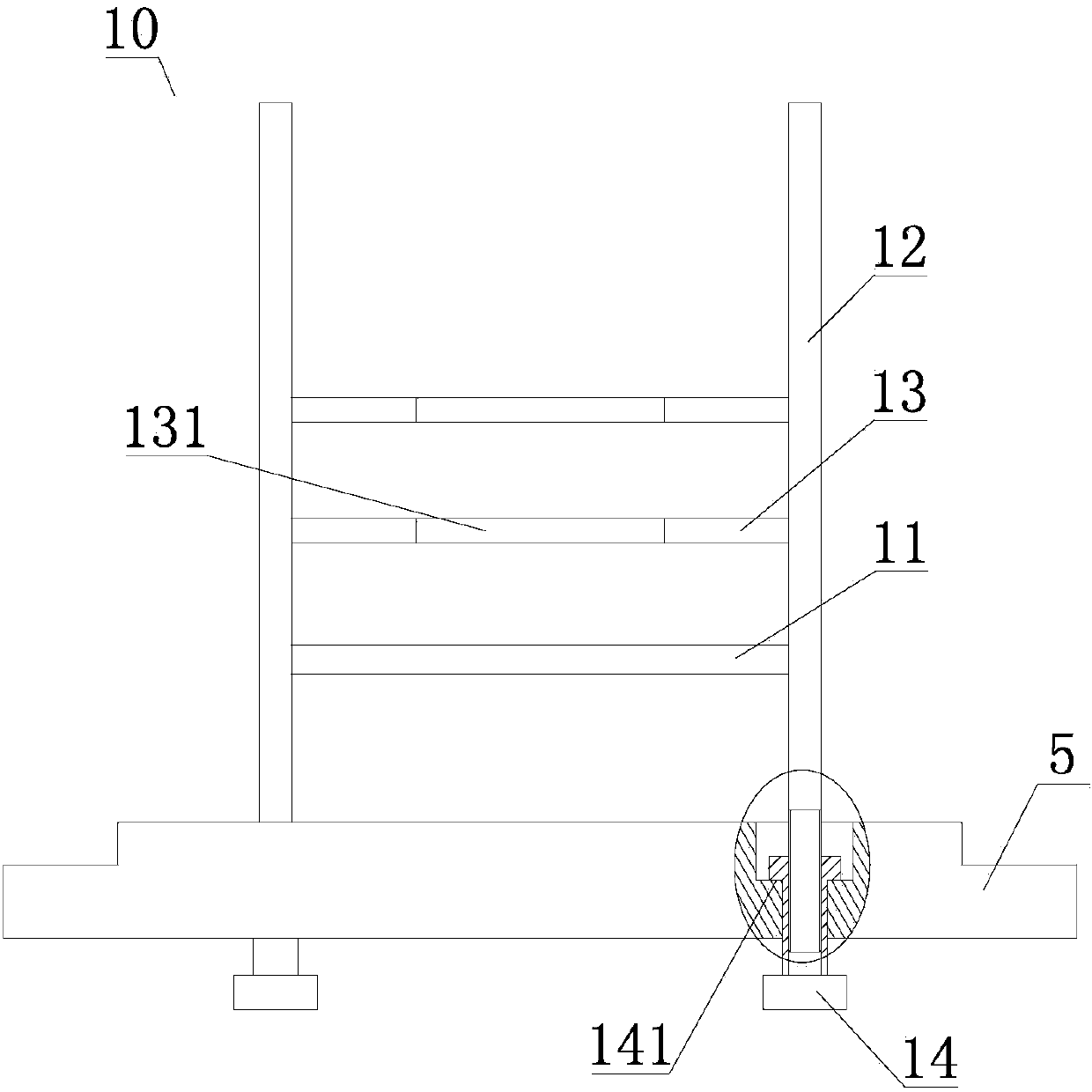

[0051] Such as figure 1 As shown, a device for preparing chalcogenide infrared glass materials proposed by an embodiment of the present invention includes a frame 1, a workbench 2, a first lifting drive device 3, a melting furnace 4, a lower furnace door 5 and a positioning device 6 .

[0052] The workbench 2 is installed on the frame 1, and the workbench 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com