Method for extracting linseed oil with supercritical CO2

A linseed oil, supercritical technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the limited problems, and achieve the effects of mature technology, high yield and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

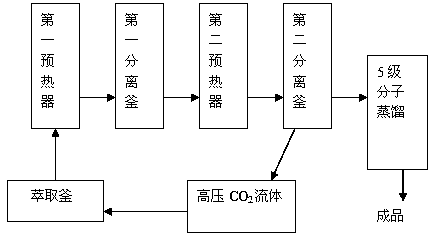

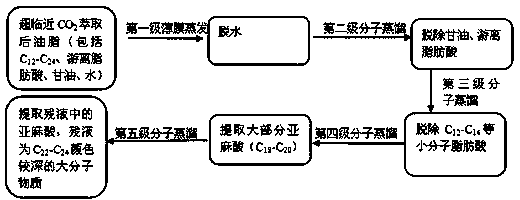

[0027] Such as figure 1 , figure 2 Shown, the supercritical CO of the linseed oil provided by the present invention 2 The extraction method comprises preheating, extraction, first separation, second separation, and molecular distillation processes, specifically comprising the following steps:

[0028] (1) Select clean linseeds without shriveled or impurities, and grind them into 40-60 mesh;

[0029] (2) Put the crushed flaxseed in step (1) in the extraction kettle for supercritical CO 2 Extraction, the specific extraction process is:

[0030] First, preheat the extraction kettle to 40~45°C, then place the material in step (1) in the extraction kettle, and adjust the high-pressure CO into the extraction kettle. 2 Fluid pressure to 28~32MPa, stable for 2 hours;

[0031] Second, high pressure CO 2 The fluid carries the dissolved substances in the extraction kettle through the first preheater and enters the first separation kettle. The temperature of the first preheater is ...

Embodiment 2

[0045] The steps for preparing linseed oil in this embodiment are the same as in Example 1, only the clean linseed oil raw material is adjusted to 0.85Kg, and the 40-mesh pulverization process is performed.

[0046] During the extraction process, the temperature in the extraction kettle was preheated to 45°C, and the high-pressure CO in the extraction kettle 2 The fluid pressure is 30MPa, stable for 2 hours; the high-pressure CO with the extract in the first separation tank 2 The fluid pressure is 10MPa, the temperature of the first preheater is 50°C; the high-pressure CO with the extract in the second separation tank 2 The fluid pressure is 6MPa, and the temperature of the second preheater is 40°C.

[0047] Supercritical CO 2 After extraction, the finished product of linseed oil is obtained after further 5-stage molecular distillation.

[0048] This embodiment finally obtains 0.305Kg of linseed oil finished product, and the extraction rate is 37.6%. The extracted linseed oil...

Embodiment 3

[0050] The steps for preparing linseed oil in this embodiment are the same as in Example 1, only the clean linseed oil raw material is adjusted to 0.86Kg, and the 60-mesh pulverization process is performed.

[0051] During the extraction process, the temperature in the extraction kettle was preheated to 45°C, and the high-pressure CO in the extraction kettle 2 The fluid pressure is 32MPa, stable for 2 hours; the high-pressure CO with the extract in the first separation tank 2 The fluid pressure is 10MPa, the temperature of the first preheater is 50°C; the high-pressure CO with the extract in the second separation tank 2 The fluid pressure is 6MPa, and the temperature of the second preheater is 35°C.

[0052] Supercritical CO 2 After extraction, the finished product of linseed oil is obtained after further 5-stage molecular distillation.

[0053] This embodiment finally obtains 0.3Kg of linseed oil finished product, and the extraction rate is 37%. The extracted linseed oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com