A kind of flame retardant for natural fiber and its preparation method and application

A natural fiber and flame retardant technology, which is applied in the field of natural fiber flame retardants and their preparation, can solve the problems of being unable to connect to natural fibers, reducing flame retardants, and being unable to be used as fabric flame retardants, so as to achieve easy operation and implementation, improving the flame retardant effect, and facilitating large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a four-necked flask, 2-sulfonic acid group-4-β-sulfate ethyl sulfonyl aniline (sulfonated para-ester) and dimethylformamide (DMF) were mixed at a mass ratio of 1:10 at room temperature at 25 Fully dissolved at ℃, adding formic acid as a catalyst.

[0029] Raise the temperature to 80°C, then drop γ-glycidyl etheroxypropyltrimethoxysilane (KH-560) with a molar ratio of 2.1 times the sulfonated para-ester into the four-necked flask at a rate of 1 drop / second, and continuously Stir. After the dropwise addition, nitrogen gas was introduced, and the reaction was continued at 80° C. for 3 h under mechanical stirring, and then the temperature was lowered to stop the reaction. After the reaction is over, the mixed liquid is distilled out of the organic solvent DMF under reduced pressure, and a viscous light yellow liquid is obtained after distillation, which is a flame retardant for natural fibers.

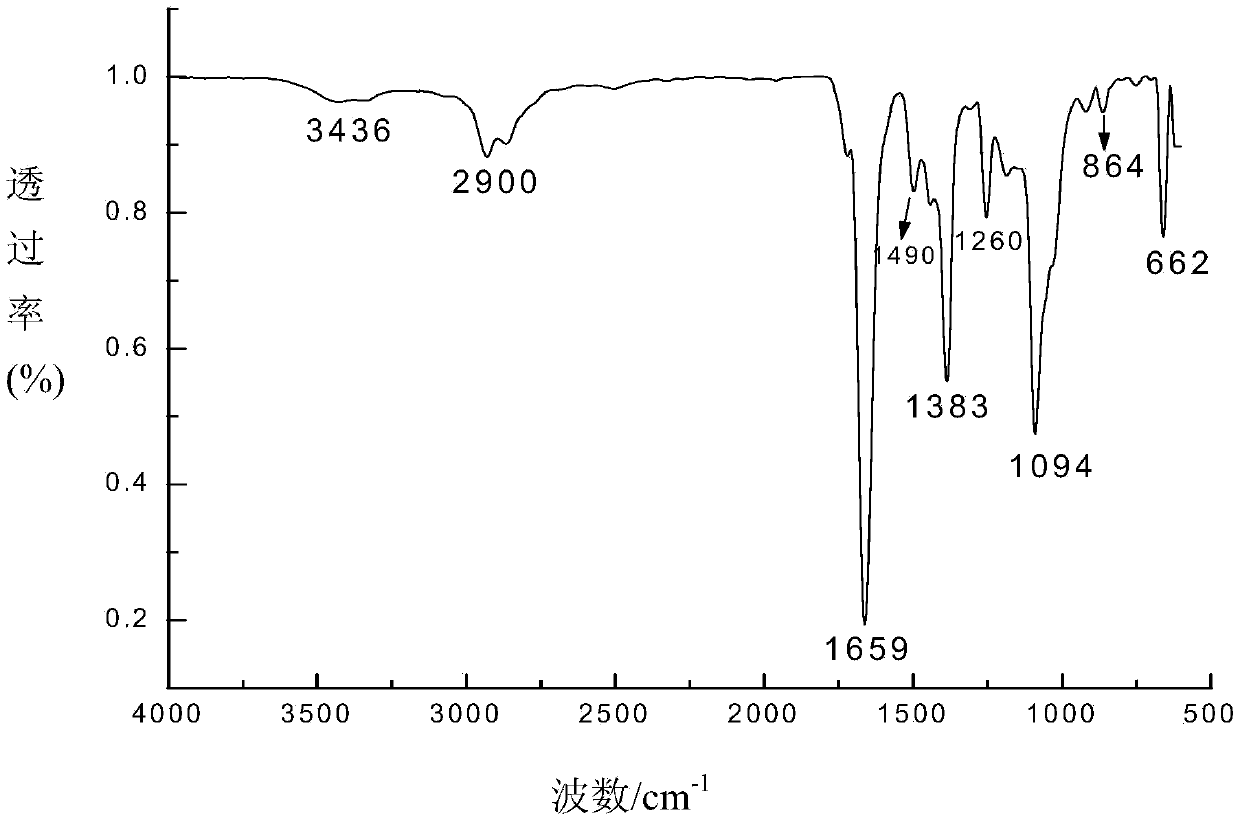

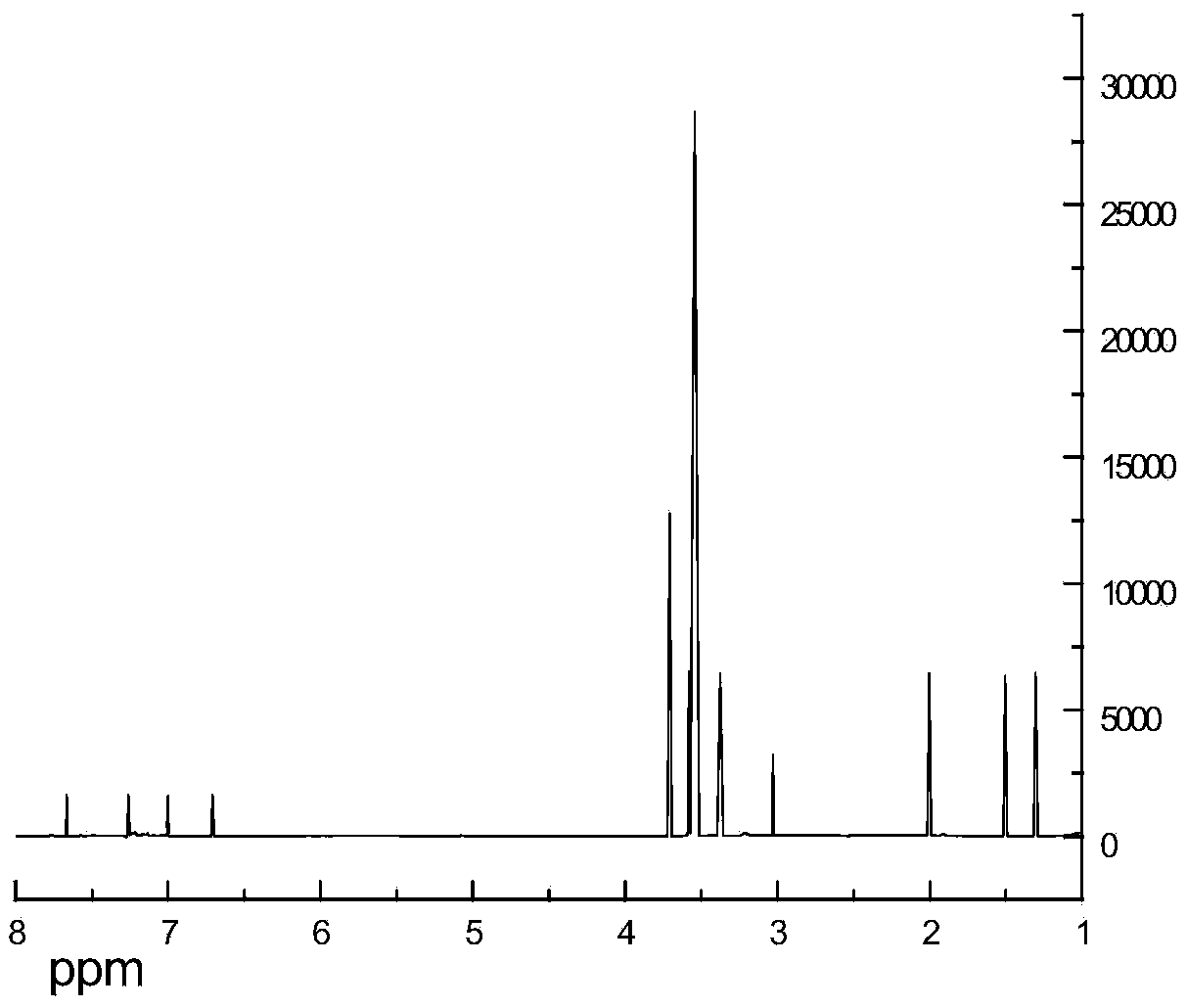

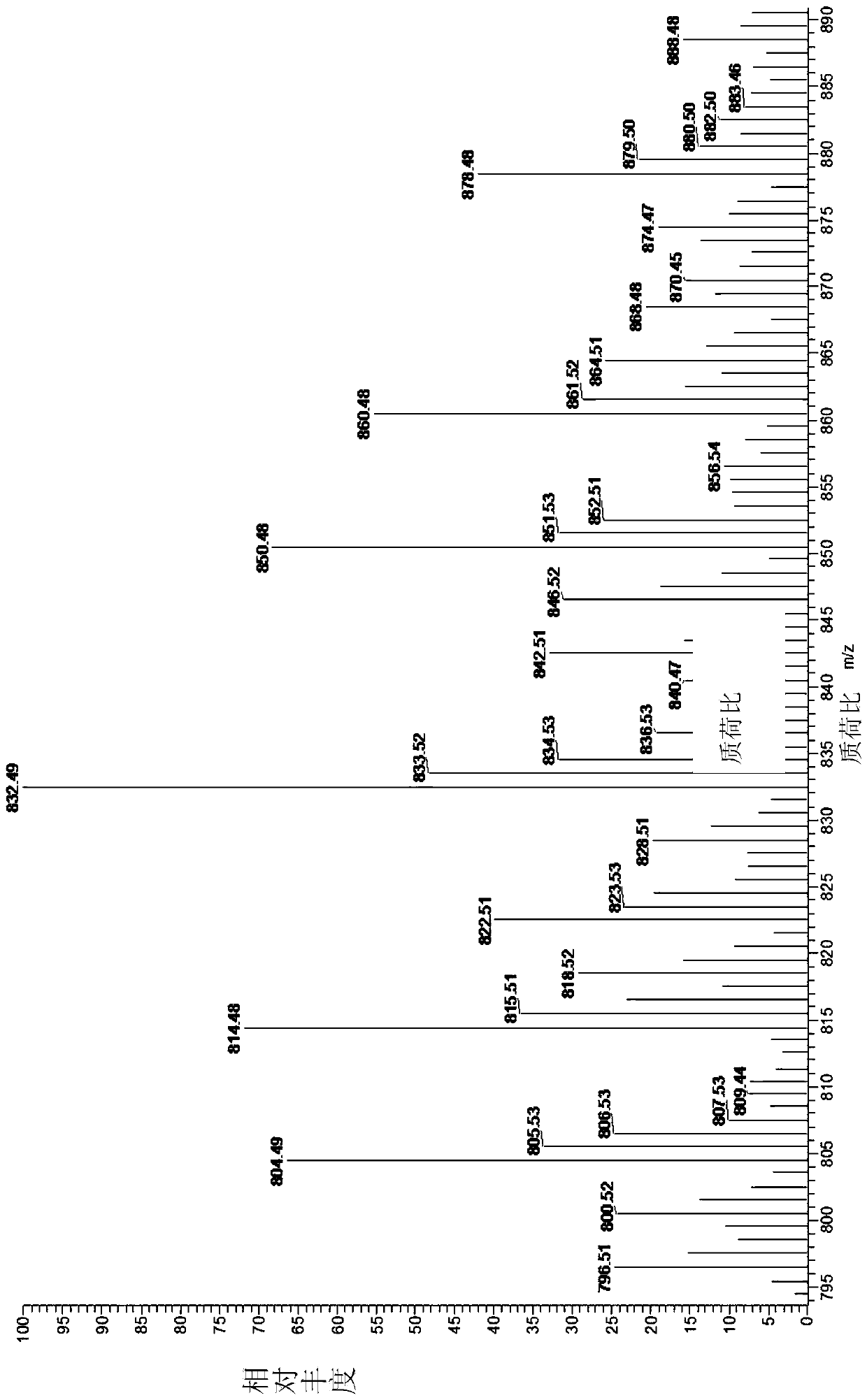

[0030] After the viscous light yellow liquid is tested by an infrared inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com