Tobacco stem fluidized bed boiler

A technology for fluidized bed boilers and tobacco stems, which is applied in the boiler field and can solve the problems of easy coking and blockage of tobacco stems, insufficient combustion, and large power consumption, and achieve the effects of reducing air pollution, sufficient combustion, and ensuring oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

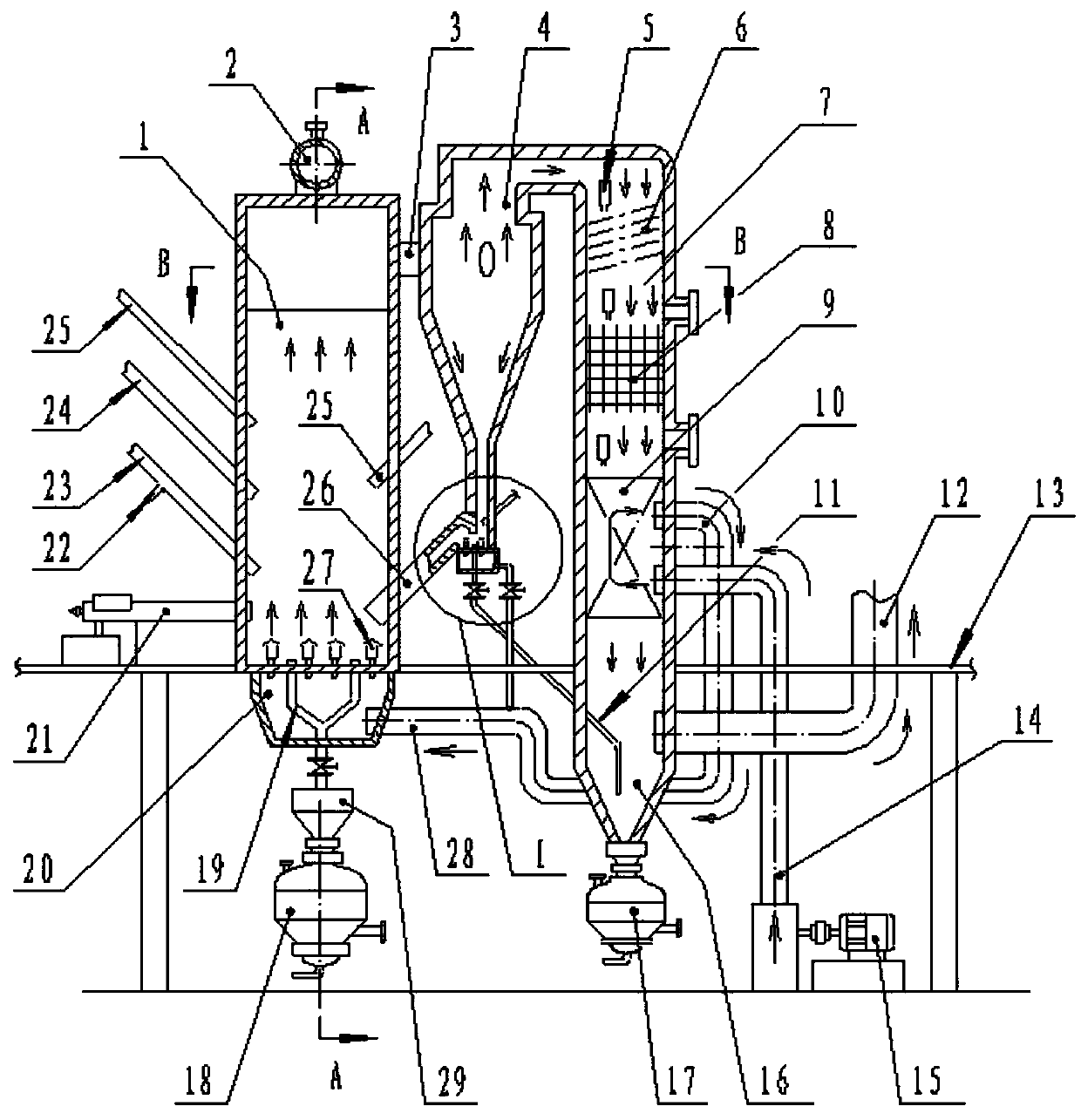

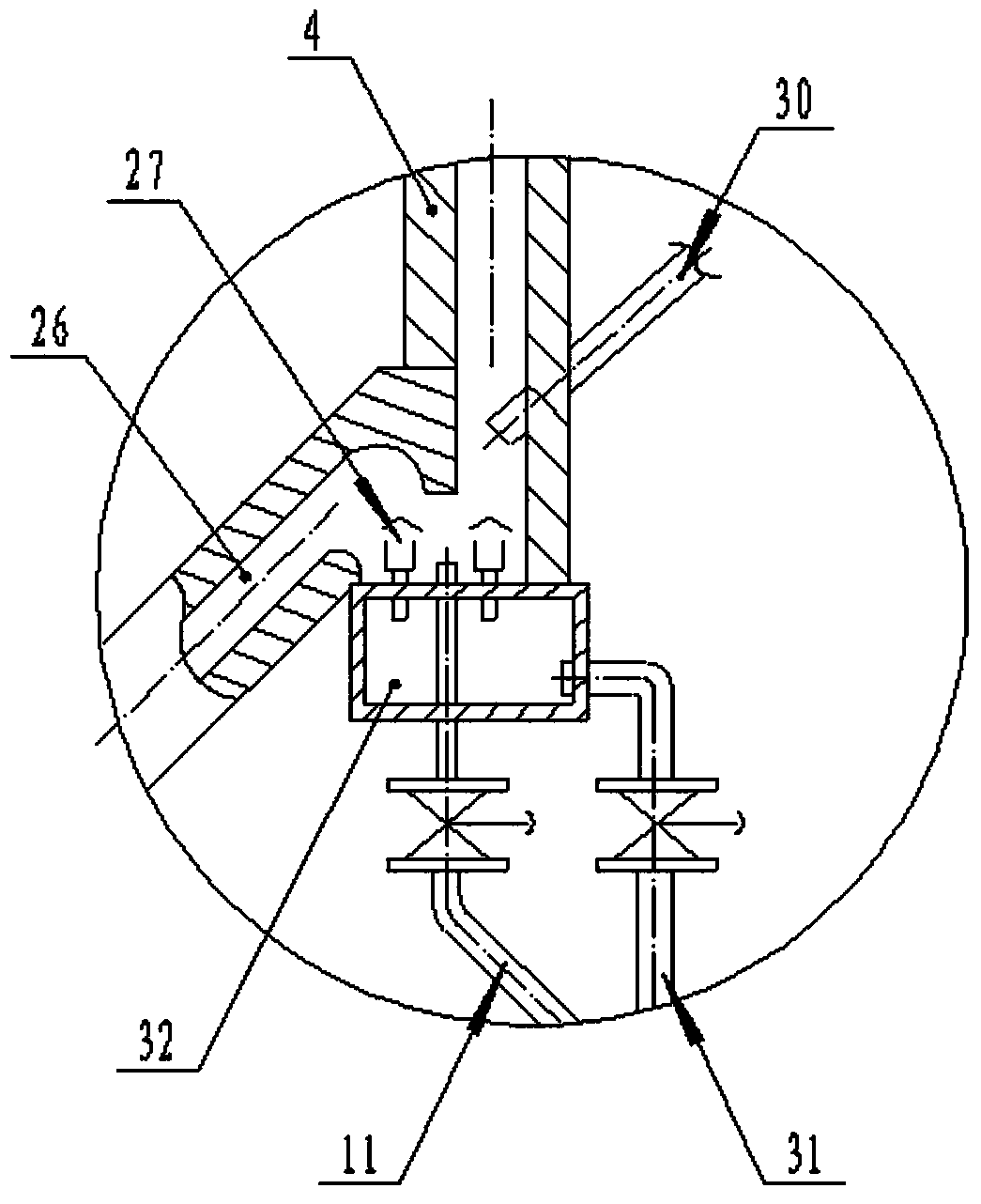

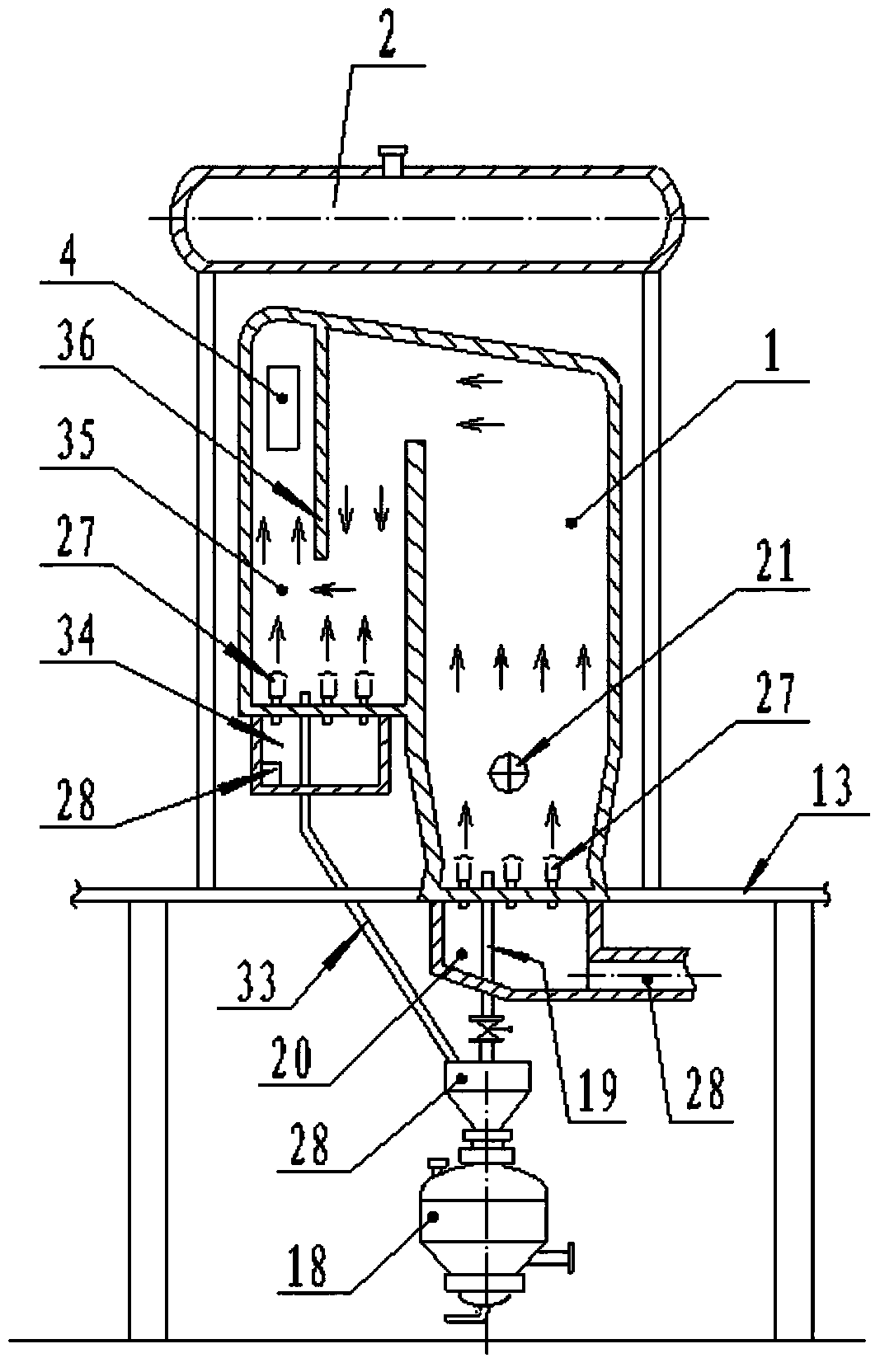

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0020] Such as Figure 1~4 Shown: body of heater is fixed on the support 13, and the top of this body of heater is fixed with the drum 2 that collects steam; A secondary combustion chamber 35 communicated with the top of the main combustion chamber constitutes, and a dividing plate 36 is arranged on the top of the secondary combustion chamber. Above-mentioned two combustion chamber bottoms are fixed with some wind caps 27, and the below of above-mentioned two combustion chambers has the main isobaric air chamber 20 and the auxiliary equal pressure air chamber 34 that communicate with it correspondingly by respective air caps 27 respectively, and these two equal pressure air chambers respectively It communicates with the air inlet pipe 28. There is a first dense phase tank 18 below the furnace body, and the first dense phase tank communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com