Brick sleeve type chimney structure with thermal insulation and anti-corrosion layer

The technology of thermal insulation and anti-corrosion layer and brick sleeve is applied in the field of brick sleeve chimney, which can solve the problems of large direct and indirect losses and damage to the chimney, and achieve the effect of economical cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

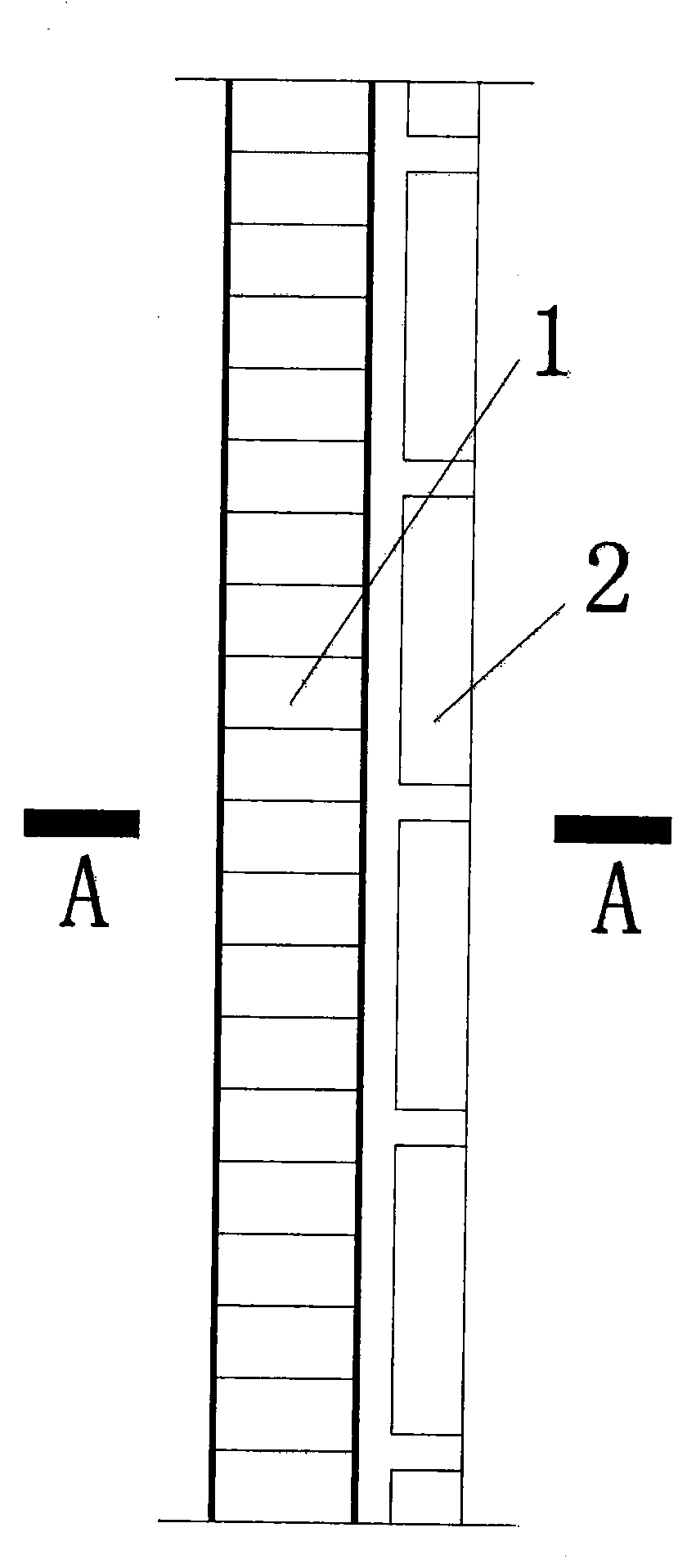

[0023] Such as figure 1 As shown, it is a partial cross-sectional view of a brick sleeve chimney structure containing an insulation and anticorrosion layer. The brick sleeve chimney structure containing an insulation and anticorrosion layer includes a brick sleeve 1 and an insulation and anticorrosion layer. The insulation and anticorrosion layer It consists of an undercoat, an adhesive and a glass brick 2, the undercoat is coated on the inner wall of the brick sleeve, and the glass brick 2 is attached to the undercoat through the adhesive.

[0024] Described undercoat is selected as high adhesion undercoat (provided by Shanghai Dehao Chemical Co., Ltd. ); the adhesive is acid-resistant elastic adhesive (provided by Shanghai Dehao Chemical Co., Ltd. ); the glass bricks are made of light-weight thermal insulation glass foam bricks.

[0025] The manufacturing process of the single-tube concrete chimney structure containing thermal insulation and anti-corrosion layer is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com