Drying box for drying electronic transformer body

An electronic transformer, drying box technology, applied in drying, furnace type, drying of solid materials, etc., to achieve the effect of simple structure, improved drying effect, and uniform drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

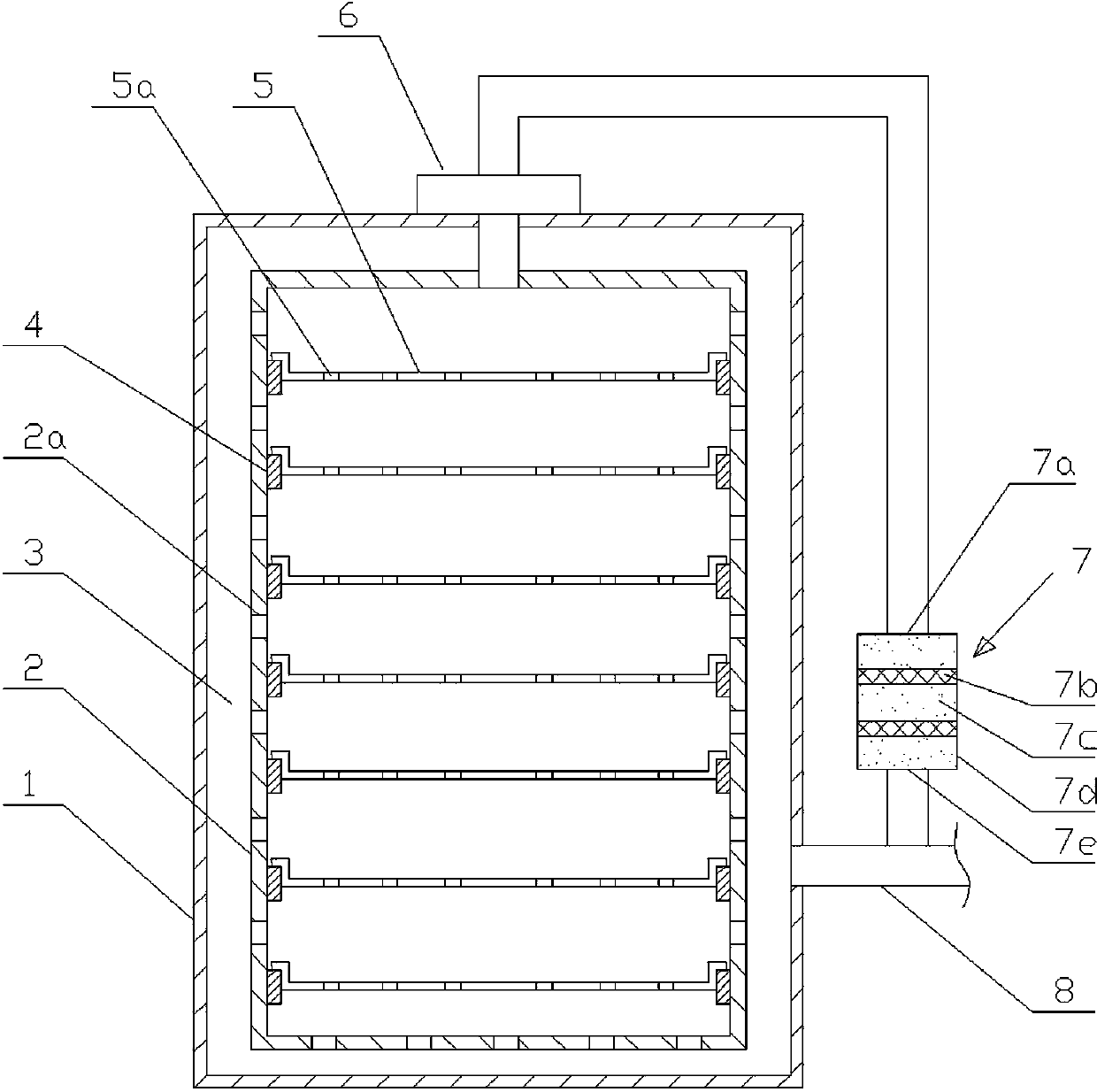

[0016] Such as figure 1 As shown, a drying box for drying the body of an electronic transformer provided by the present invention includes a box shell 1 and a box inner wall 2, and an air duct 3 communicating with an air intake pipe 8 is provided between the shell and the inner wall , a heating device is arranged in the air duct, and a group of ventilation holes 2a communicating with the air duct 3 are evenly distributed on the inner wall 2 of the box, and a set of supporting plates 4 are respectively provided on the corresponding sides of the inner wall, and there are sliding holes between the corresponding supporting plates 4 Cooperating storage trays 5, each storage tray 5 bottom is provided with a group of through holes 5a, the outer side of the box shell 1 is provided with an exhaust device 6, one end of the exhaust device communicates with the inner wall 2 of the cabinet through a pipeline, and the other end is connected with a drying device. Filtration device 7, describ...

Embodiment 2

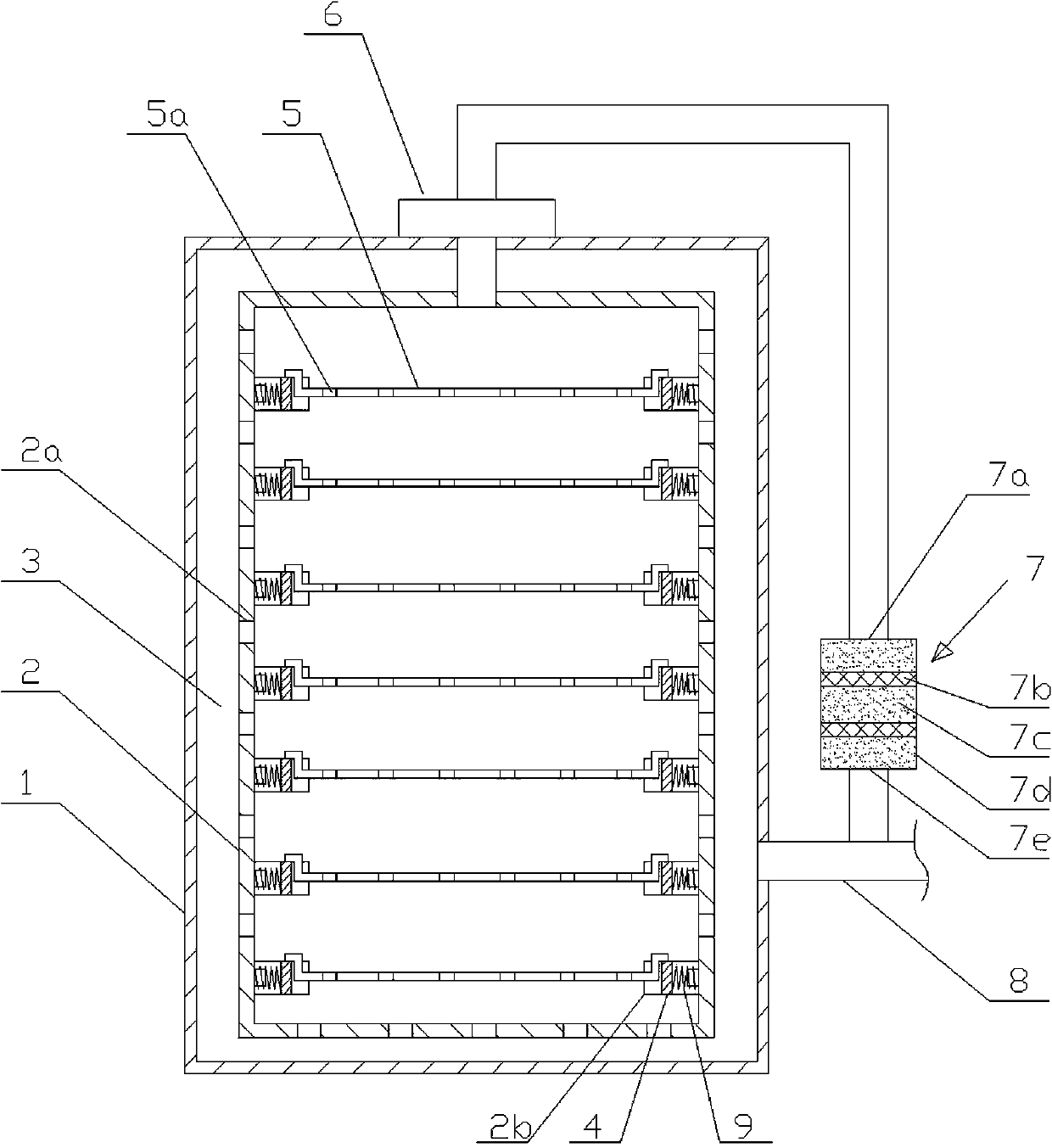

[0018] Such as figure 2 As shown, a drying box for drying the body of an electronic transformer provided by the present invention includes a box shell 1 and a box inner wall 2, and an air duct 3 communicating with an air intake pipe 8 is provided between the shell and the inner wall , a heating device is provided in the air duct, and a group of ventilation holes 2a communicating with the air duct 3 are evenly distributed on the inner wall 2 of the box. A set of supporting plates 4 are respectively arranged on the corresponding sides of the inner wall, and the corresponding box at both ends of each supporting plate 4 The internal wall 2 is provided with a chute 2b, and the supporting plate 4 is slidably matched with the chute 2b along the horizontal direction. The symmetrical position on one side of each supporting plate 4 is respectively provided with a spring 9, one end of the spring 9 is connected with the supporting plate 4, and the other One end is connected and matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com