Measuring device and measuring method for axial-distribution data of section of rusted steel bar

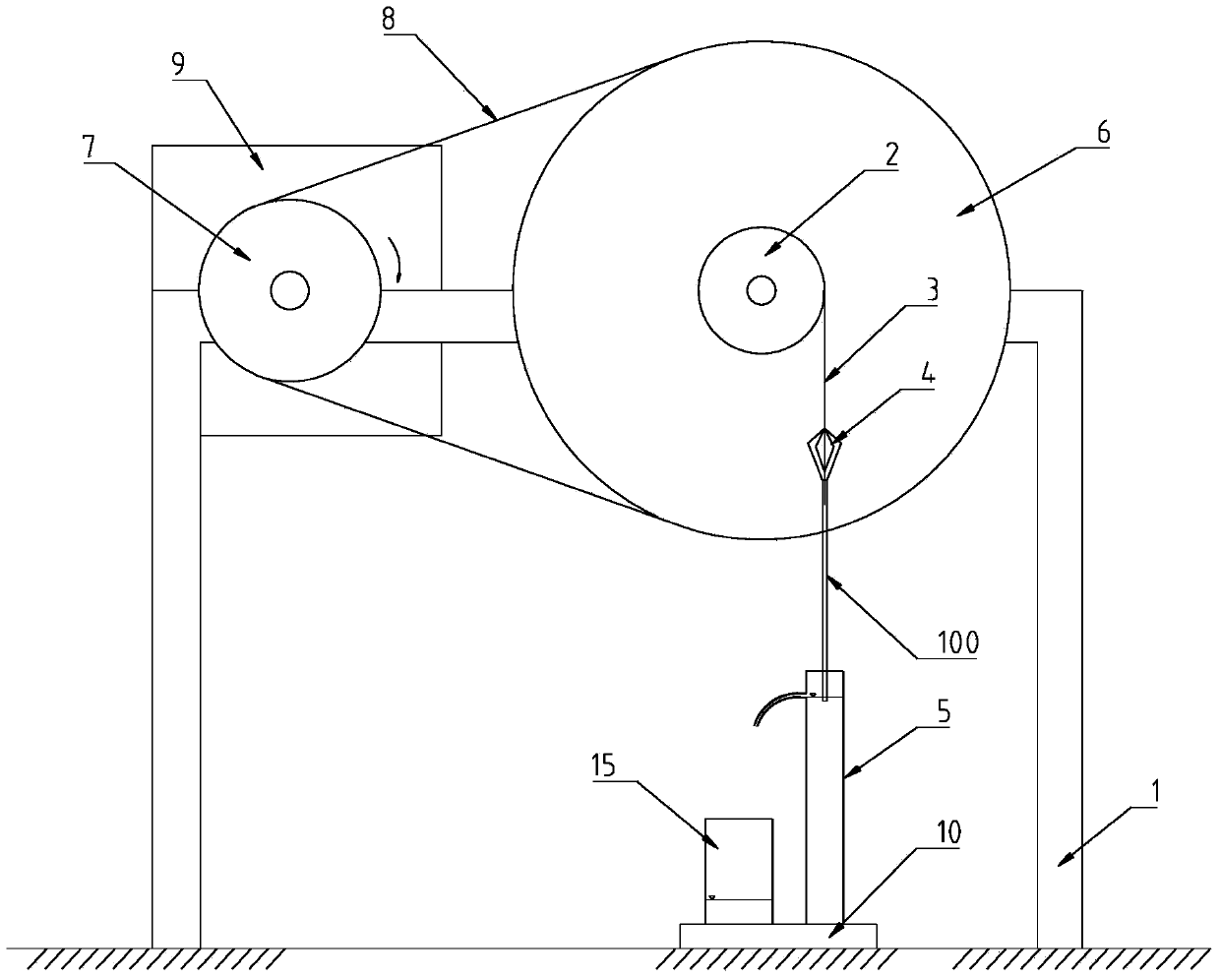

A measuring device and a technology for axial distribution are applied in the field of measuring devices for the axial distribution data of corroded steel bar sections, which can solve the problems of test cost and threshold increase, and achieve the effects of high detection efficiency, simple test equipment and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

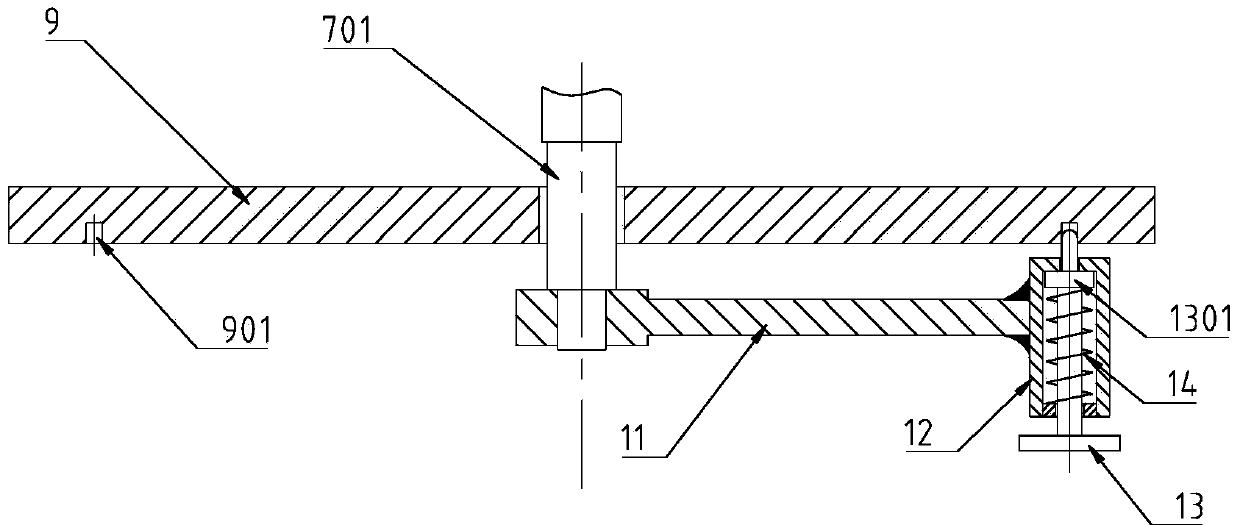

[0076] The difference between implementation example 2 and implementation example 1 is that gears are directly used for transmission. Compared with example 1, chain transmission is directly used. The gear meshing transmission has the characteristics of high transmission efficiency, low noise, and small footprint. However, the direct use of gear meshing transmission has relatively high requirements for lubricity.

[0077] The measuring device of embodiment 3 of the present invention corroded steel bar section axial distribution data is as Figure 4 As shown, Embodiment 3 adopts a two-stage gear reduction mechanism. Compared with Embodiment 2, the second small gear 20 and the second large gear 21 are added, the structure is more compact, the transmission ratio is larger, and the measurement accuracy is higher.

Embodiment 4

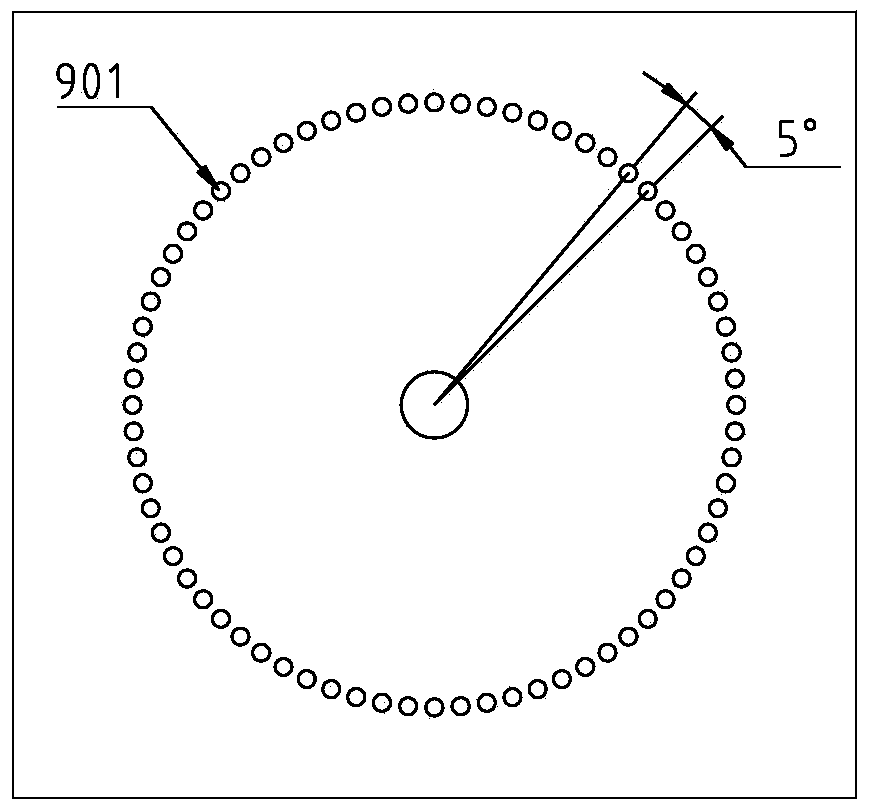

[0080] The reduction mechanism of embodiment 4 is a worm gear reducer. Compared with embodiments 1-3, the reduction ratio of the worm gear reducer is large, the volume is small, and it can be self-locking; because the reduction ratio of the worm gear reducer is large, the index The distance between the disc indexing holes or the ratchet teeth can be increased, which is convenient for control and operation during testing.

[0081] The measuring device for the cross-section axial distribution data of corroded steel bars according to the present invention is simple in operation, low in test threshold and cost, high in detection efficiency and high in detection accuracy, and can accurately obtain data on the axial distribution of corroded steel bar cross-sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com