Intelligent tool capable of being flexibly expanded and dynamically configured

A dynamic configuration and intelligent technology, applied in measurement devices, instruments, electronic circuit testing, etc., can solve the problems of high manual participation, inconsistent operation methods, mental fatigue of testers, etc., and achieve good compatibility, good compatibility and adaptability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

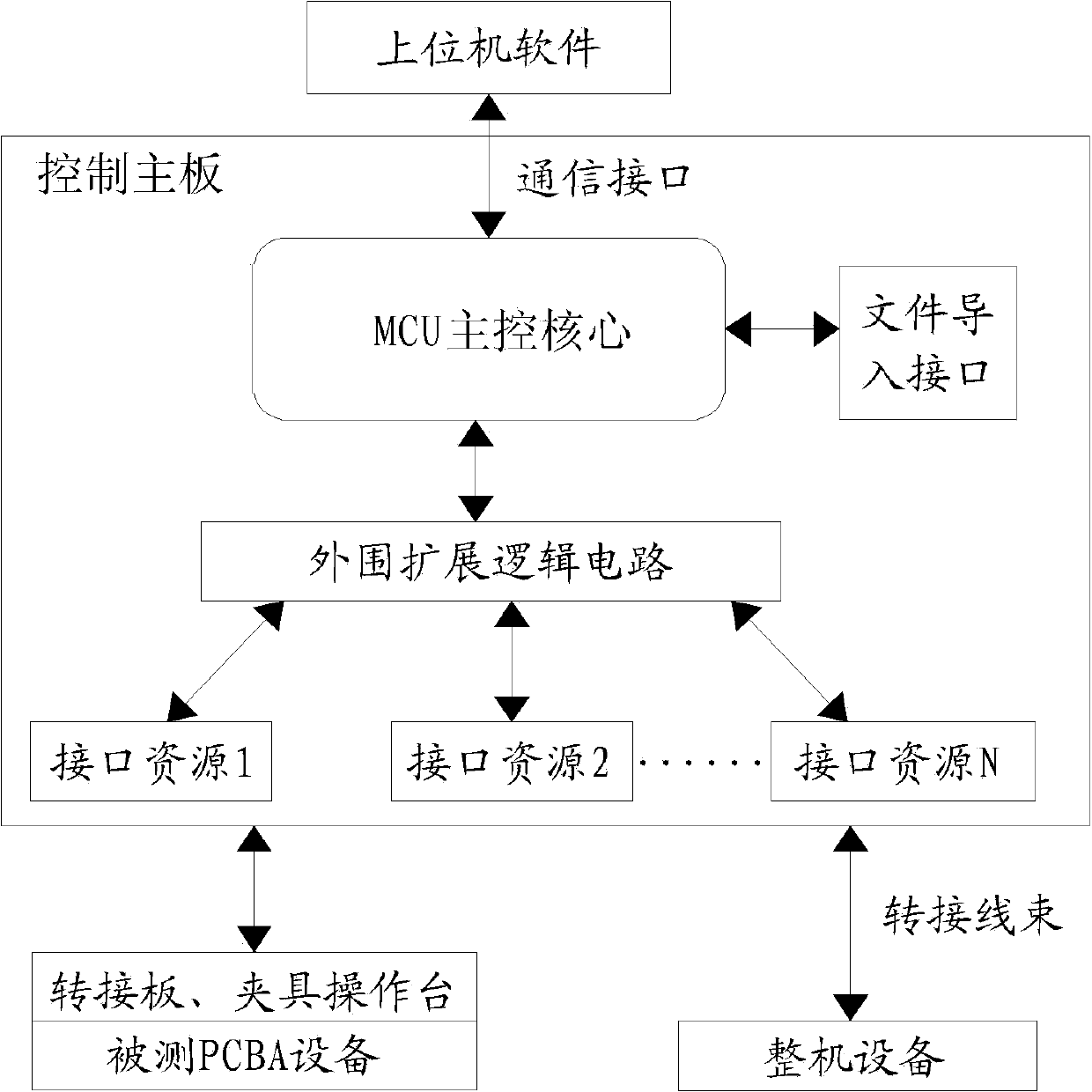

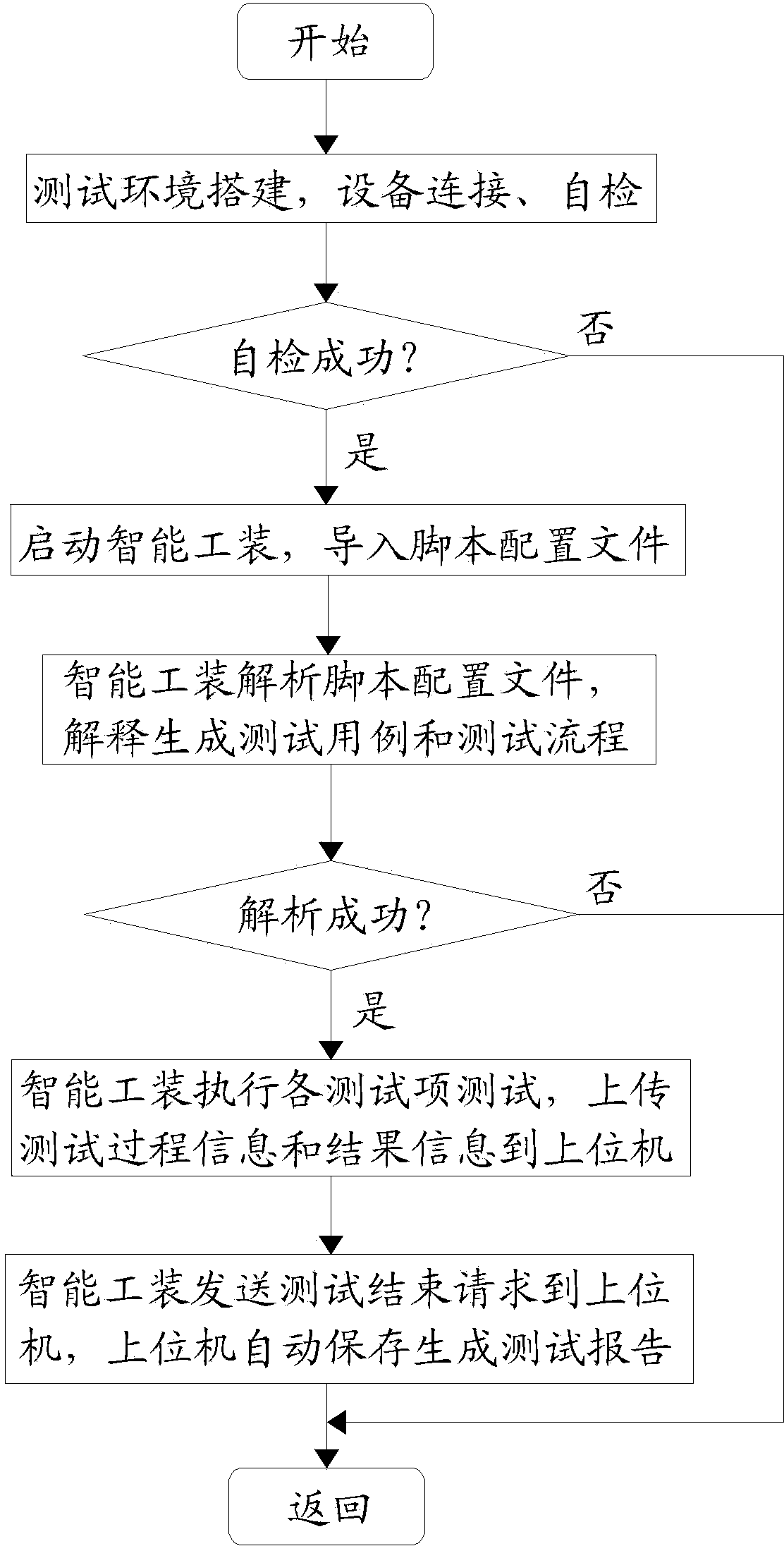

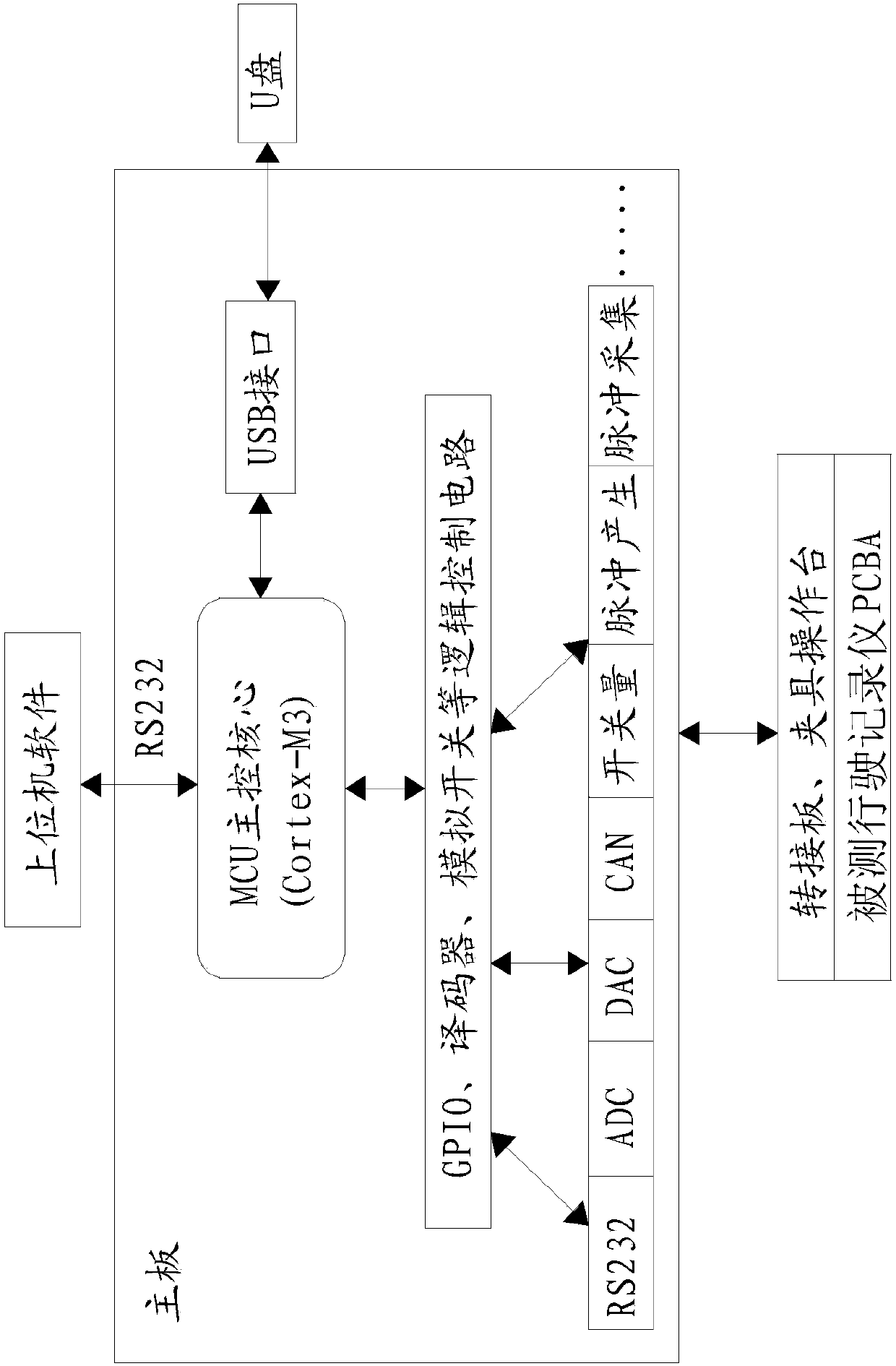

[0034] The invention proposes an intelligent tool that can be flexibly expanded and dynamically configured. The hardware part of the intelligent tool is an intelligent and automatic test platform, which is highly practical, stable and reliable. The present invention adopts the design concept with test items as the object, and realizes the flexible allocation of test cases and the dynamic combination of test processes through script configuration files, so that the intelligent tooling can be compatible and adapted to different types of tested equipment or tests of different processes, reducing the frequency of tooling modification and maintenance workload, and improve the compatibility and applicability of smart tooling. The design idea of the present invention is to abandon the previous design idea of testing equipment as the object, adopt the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com