Wire wrapping device facilitating wire wheel wire wrapping quality

A wire winding device and wire wheel technology, applied in the field of electronic product production equipment, can solve the problems of large equipment investment, manpower, energy consumption, large volume of wire winder, and many control points, etc., and achieve simple structure, good wiring quality, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

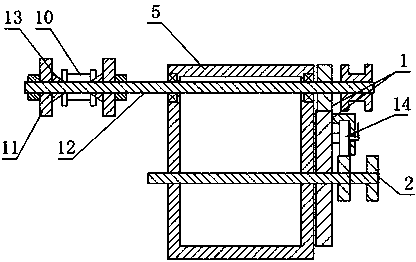

[0027] Such as Figure 1 to Figure 2 As shown, the winding device that is beneficial to the winding quality of the wire wheel includes a frame 5, a wire wheel fixing mechanism, a fixing mechanism braking mechanism, a metering part 14 and a wire guide mechanism;

[0028] The wire wheel fixing mechanism comprises a wire wheel rod 12 arranged on the frame 5 and two positioning cones 13 and two wire wheel ribs 11 arranged on the wire wheel rod 12, and the wire wheel ribs 11 are arranged on the wire wheel rod 12 The axial position of the shaft is adjustable, the positioning cone 13 is a truncated conical shape with a central hole, and the positioning cone 13 is set on the wire wheel rod 12 between the wire wheel ribs 11, the two positioning cones 13 The small diameter end is opposite;

[0029] The braking mechanism of the fixing mechanism includes a driving wheel shaft 2 and a transmission tooth 1, and the transmission tooth 1 includes two mutually meshing gears, and the two gears...

Embodiment 2

[0036]The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 2 As shown, in order to make the present invention applicable to spools within a certain size range, and to cause less damage to the end face of the spool during installation and disassembly of the spool, the spool rib 11 includes clearance fits with the spool rod 12 respectively. Bezel and nut for threaded connection.

Embodiment 3

[0038] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 2 As shown, since the lead wires used for IC components generally have a smaller wire diameter and less coil resistance, in order to increase the working capacity of the present invention, the gear transmission between the driving wheel shaft 2 and the wire wheel rod 12 is a speed-up transmission.

[0039] For the benefit of the winding quality of the wire wheel, it is necessary to ensure the relative position of the wire wheel rod 12 and the guide wheel 10 in the present invention. For the convenience of manufacturing and assembly costs of the present invention, the guide disc shaft 4, guide shaft 3 and wire wheel The rod 12 is connected with the frame 5 through a bearing seat arranged on the frame 5 , and the driving wheel shaft 2 and the frame 5 form clearance fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com