Steel wire rod or bar steel with excellent cold forgeability

A technology of steel wire rod and cold forgeability, applied in the field of steel wire rod or bar steel, which can solve the problems of steel cracking, mold cracking, deformation resistance and high deformation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

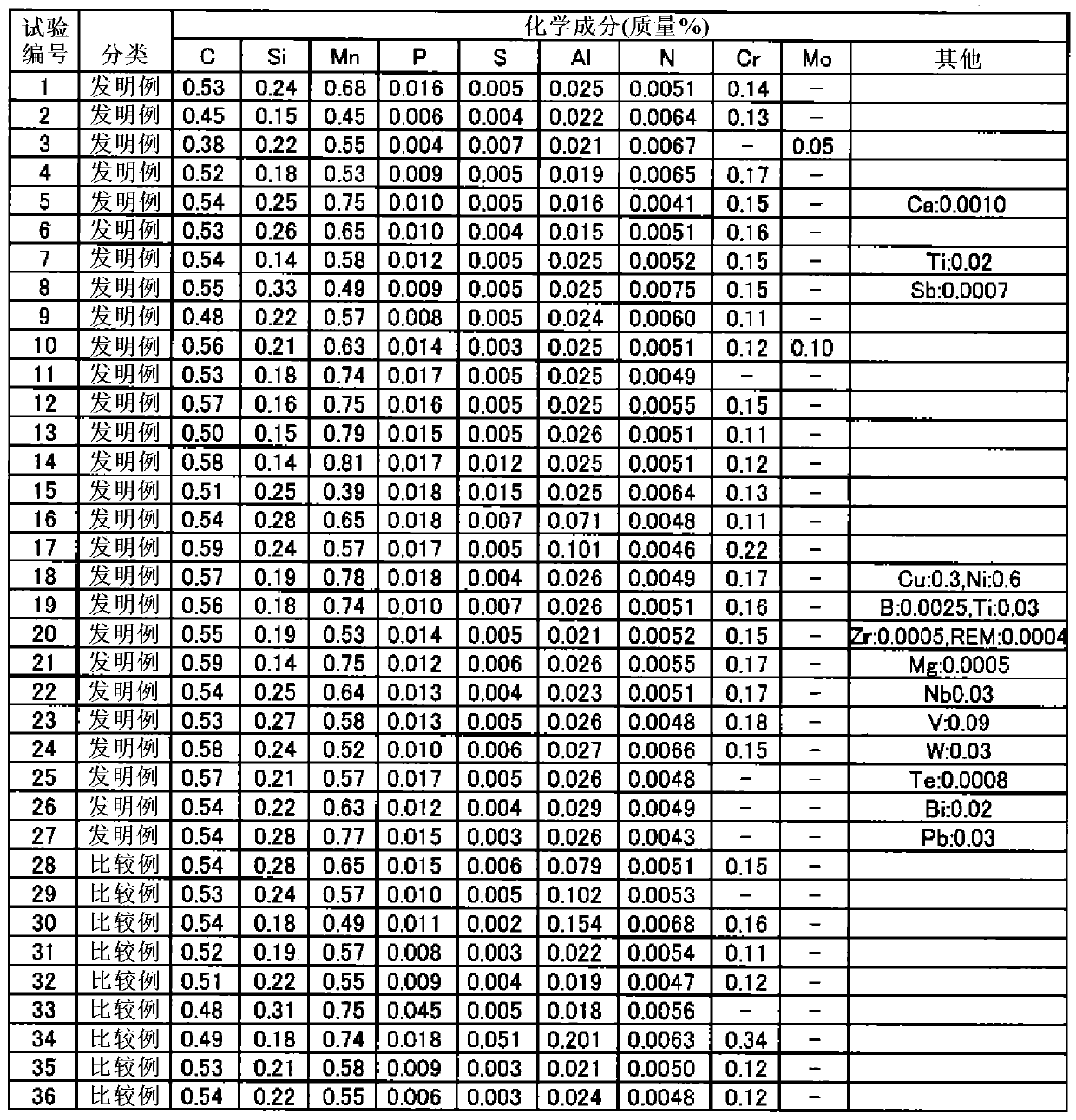

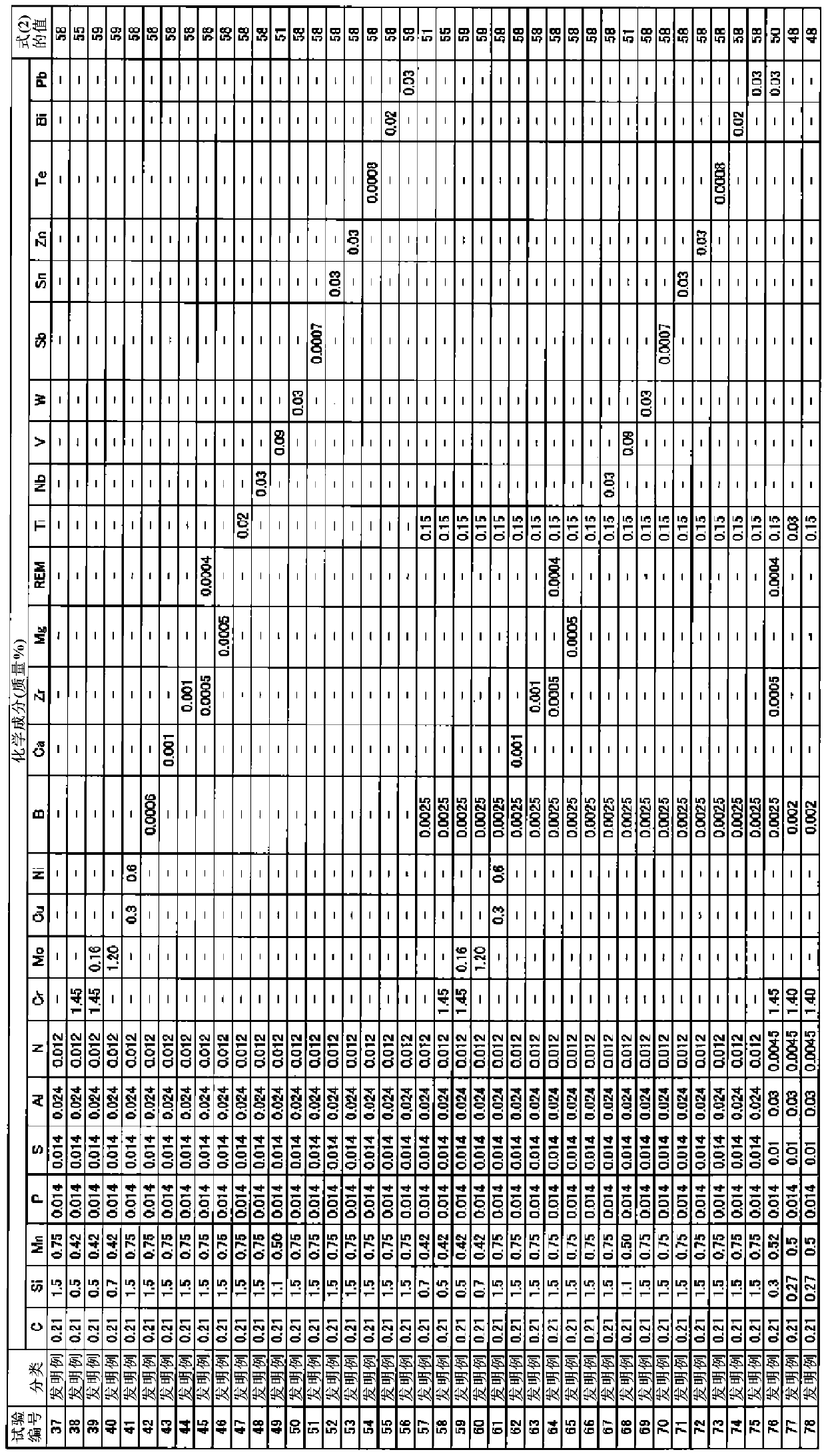

[0108] Hereinafter, the present invention will be specifically described based on examples. It should be noted that these examples are for illustrating the present invention, but do not limit the scope of the present invention.

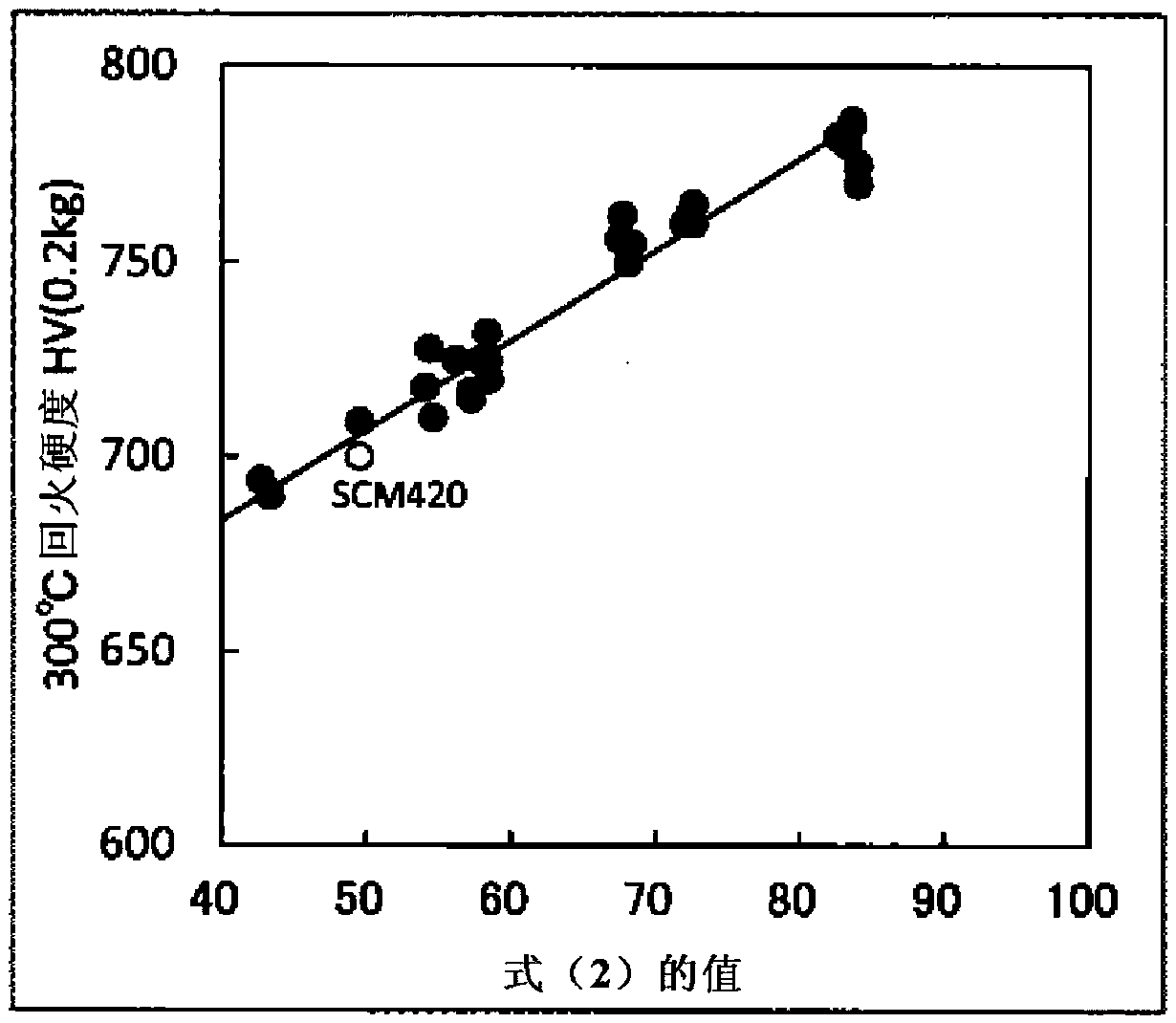

[0109] According to the conditions of Table 3 and Table 4, a 162 mm square billet having the chemical composition shown in Table 1 and Table 2 was rolled. In all examples except Test No. 17, test pieces were taken from rolled steel bars, and the microstructure, hardness distribution, and surface roughness after pickling were investigated. However, for Test No. 17, a steel bar of φ44 was produced by turning the outer periphery of one side by 0.5 mm after rolling, and a test piece was taken from the steel bar, and the microstructure, hardness distribution, and surface roughness were investigated.

[0110] Next, after rolling (Test No. 17 was after cutting), the steel bar that had been temporarily cooled to room temperature was heated and kept in the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com