Internal combustion engine

A technology for internal combustion engines and compressors, which is applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., and can solve problems such as backflow of mixed gas from cross-cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

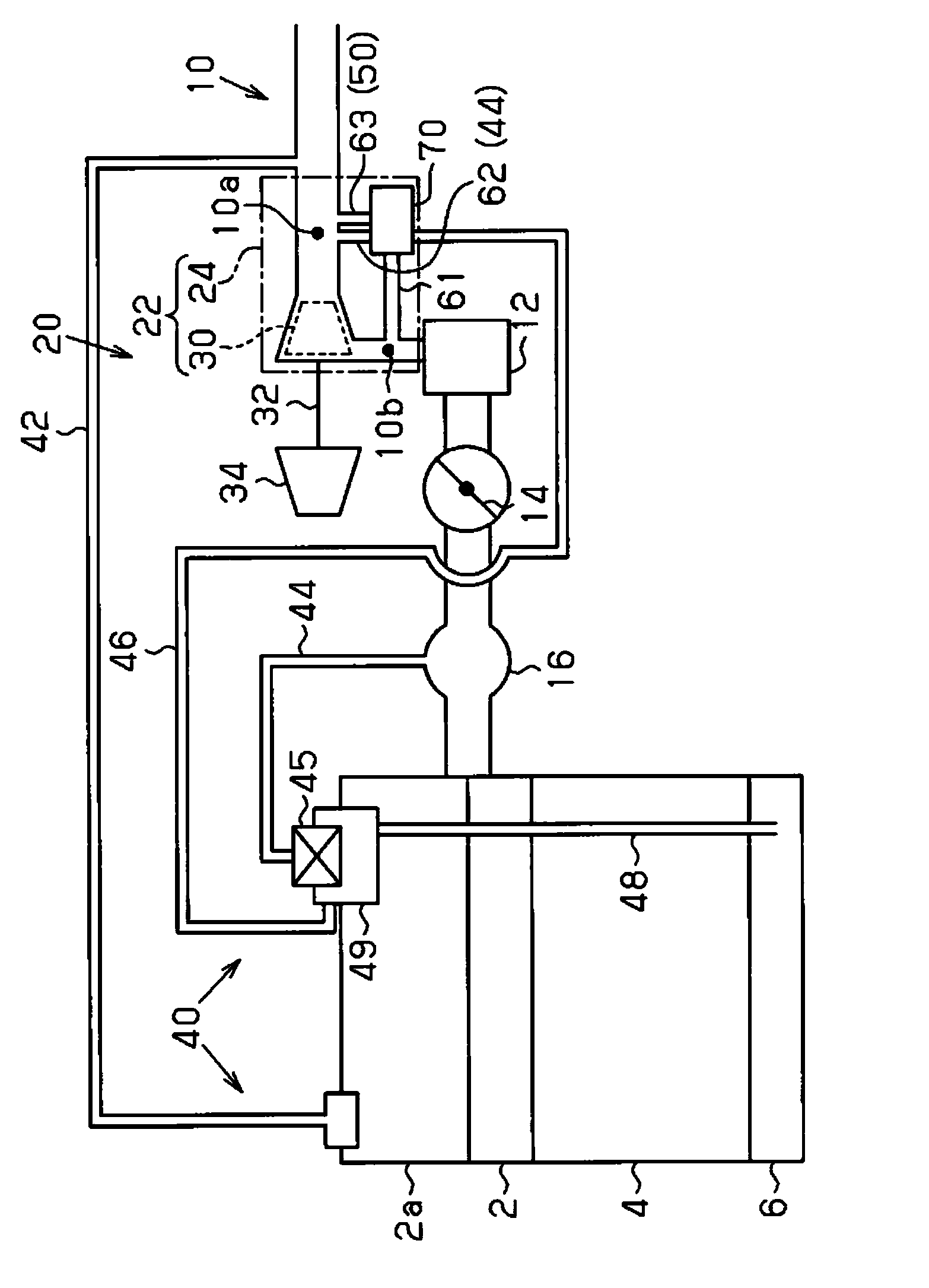

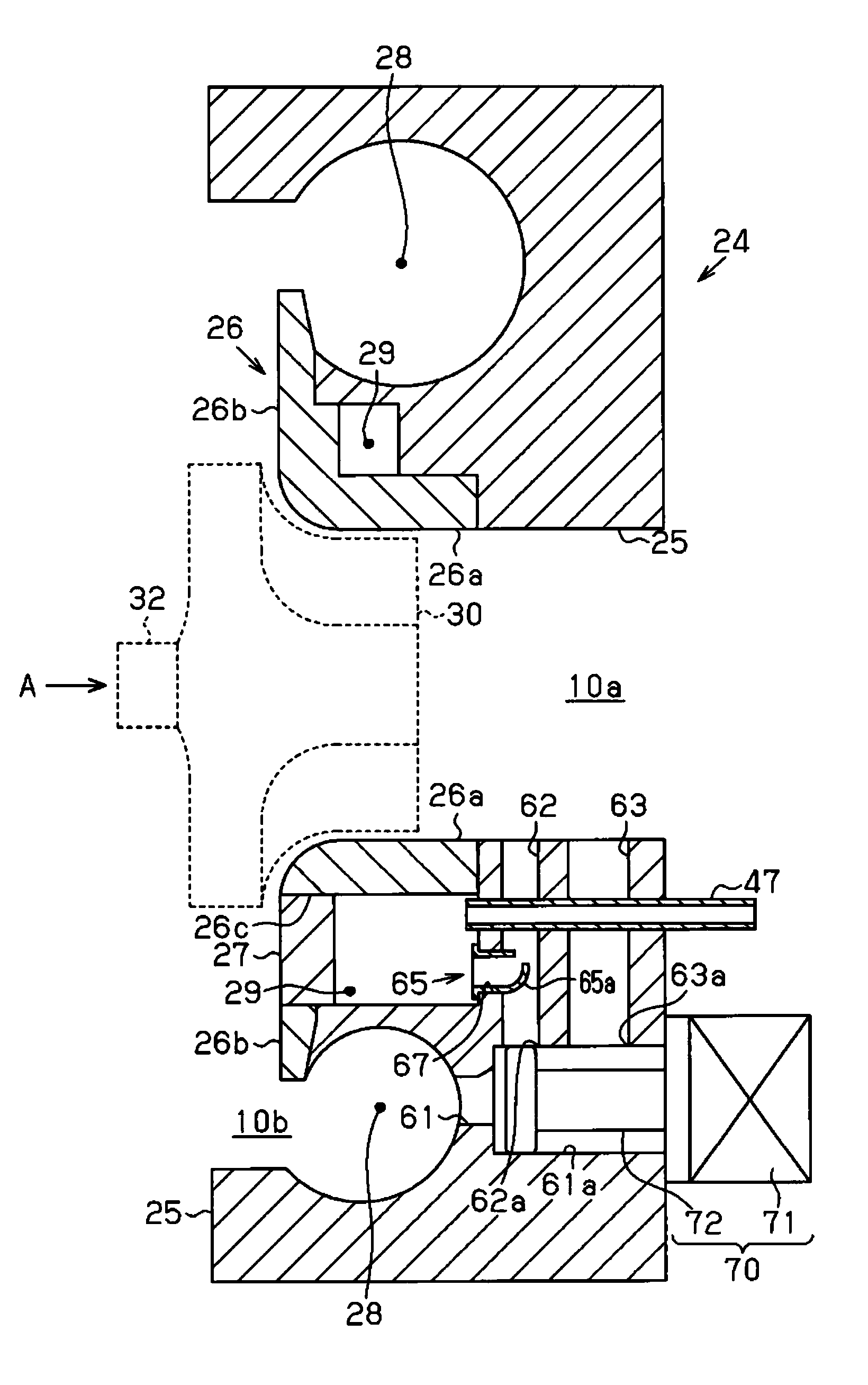

[0047] Below, refer to Figure 1 ~ Figure 4 A first embodiment in which the internal combustion engine of the present invention is embodied will be described.

[0048] Such as figure 1 The internal combustion engine is shown with a cylinder head 2 , a cylinder block 4 and a crank housing 6 . In addition, a head cover 2 a is attached to an upper portion of the cylinder head 2 .

[0049] An intake passage 10 for introducing air to each cylinder is connected to the cylinder head 2 .

[0050] A compressor 22 , an intercooler 12 , a throttle valve 14 , and an intake manifold 16 are provided in this order from the upstream side in the intake passage 10 .

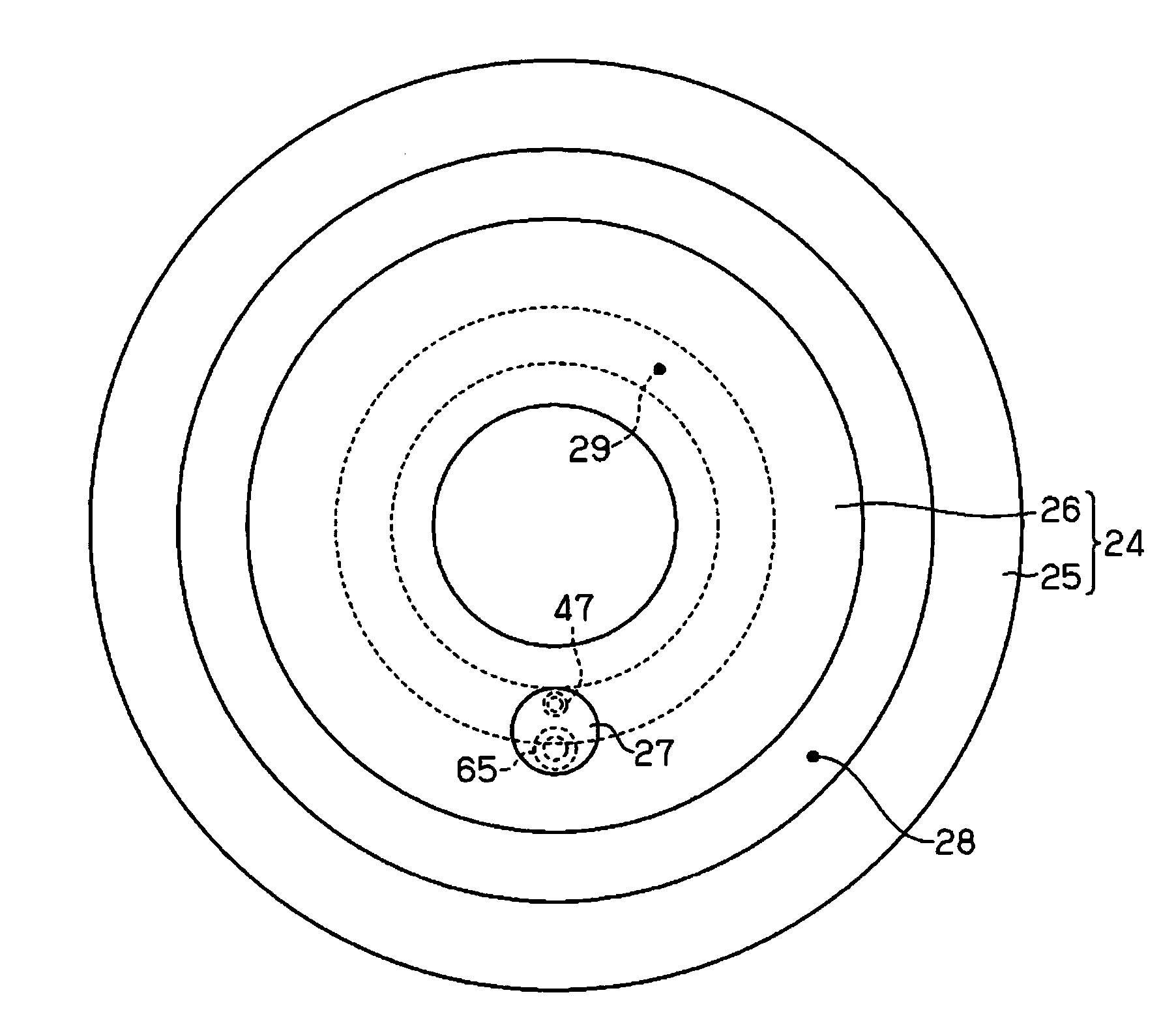

[0051] The compressor 22 has an impeller 30 provided in the intake passage 10 , and a compressor housing 24 surrounding the impeller 30 . In addition, in the intake passage 10 , a portion on the upstream side of the impeller 30 is referred to as an upstream portion 10 a , and a portion on the downstream side of the impeller 30...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap