Temperature Sensor

A technology of temperature sensor and thin film thermistor, which is used in thermometers, resistors with negative temperature coefficients, instruments, etc. Thermal properties, good B constant, flexibility, and less unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

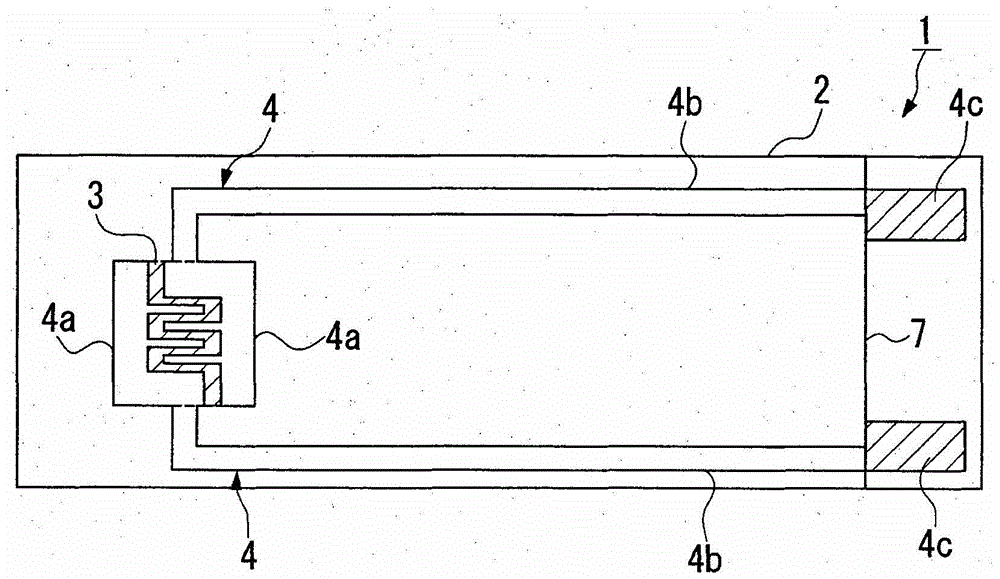

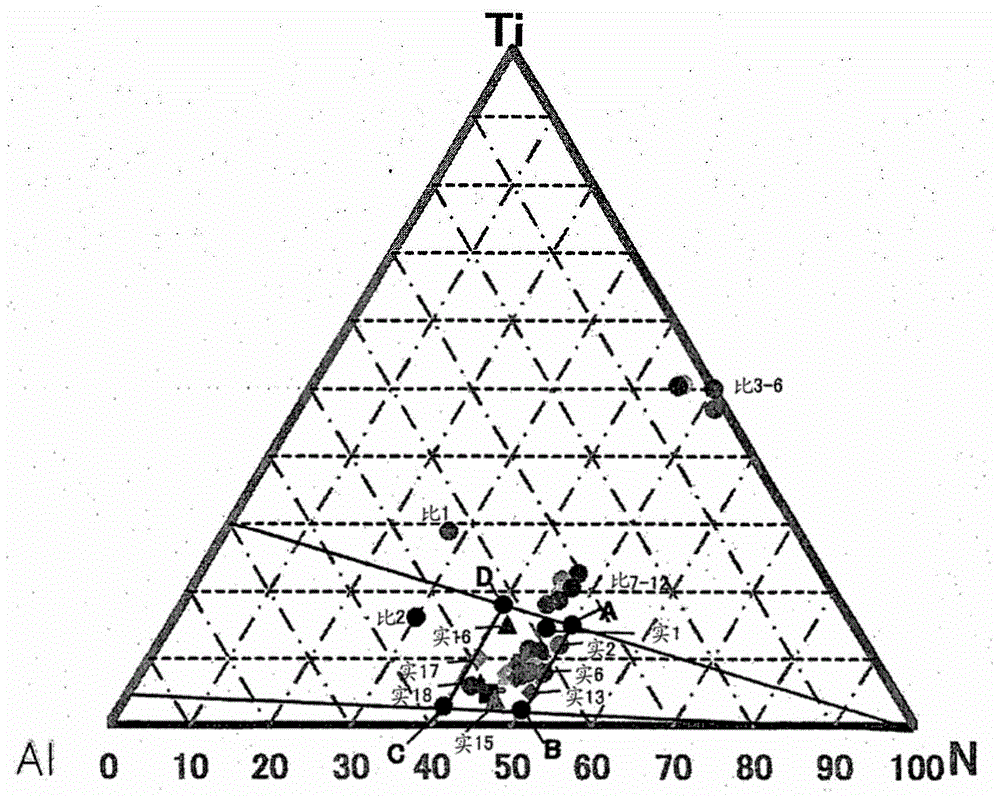

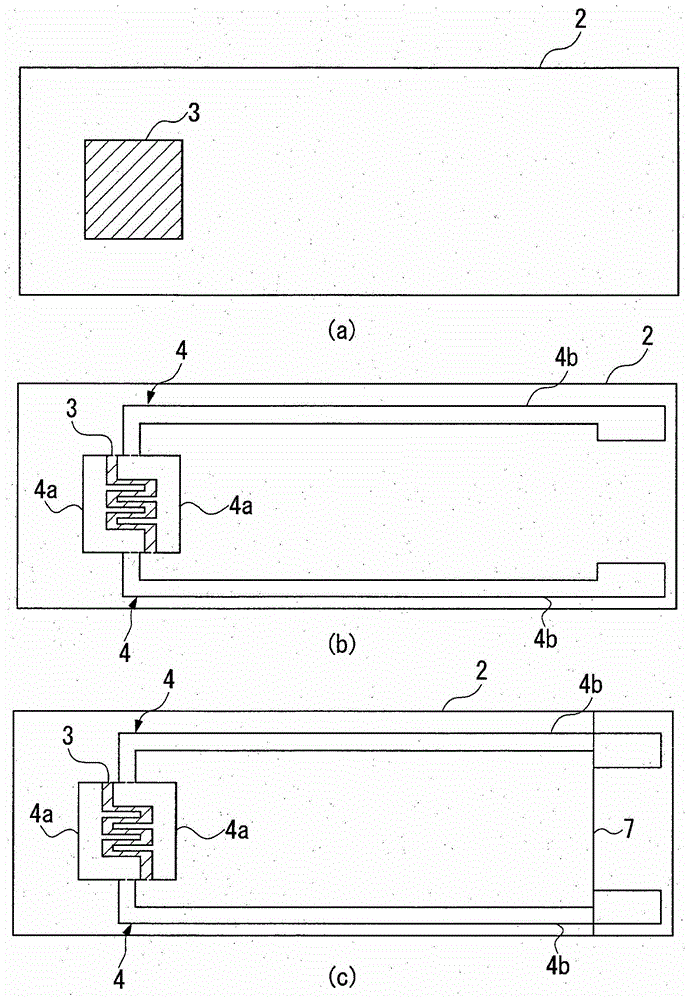

[0054] Next, for the temperature sensor involved in the present invention, refer to Figure 5 to Figure 13 The result of evaluation by the Example produced based on the said embodiment is demonstrated concretely.

[0055]

[0056]For the temperature sensors of Example 1 and Example 2 for bending produced according to the above-mentioned first and second embodiments, bending tests of concave and convex bending were performed alternately 100 times each with a curvature of radius 6 mm, and observation was performed after the test. Check the thin film thermistor for cracks. In addition, regarding the presence or absence of this crack, the thin film thermistor part was observed from the insulating film side. In addition, the electrical properties changes before and after the test were also evaluated. These evaluation results are shown in Table 1.

[0057] In addition, as a comparison, Comparative Example 1 for bending of a pair of opposing electrode portions smaller than the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com