Ultrasonic detection image three-dimensional calibration method

A technology of three-dimensional calibration and ultrasonic detection, which is applied in ultrasonic/acoustic/infrasonic diagnosis, acoustic diagnosis, infrasonic diagnosis, etc., to reduce the fan-shaped divergence effect of ultrasonic beam, improve calibration accuracy and reconstruction accuracy, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

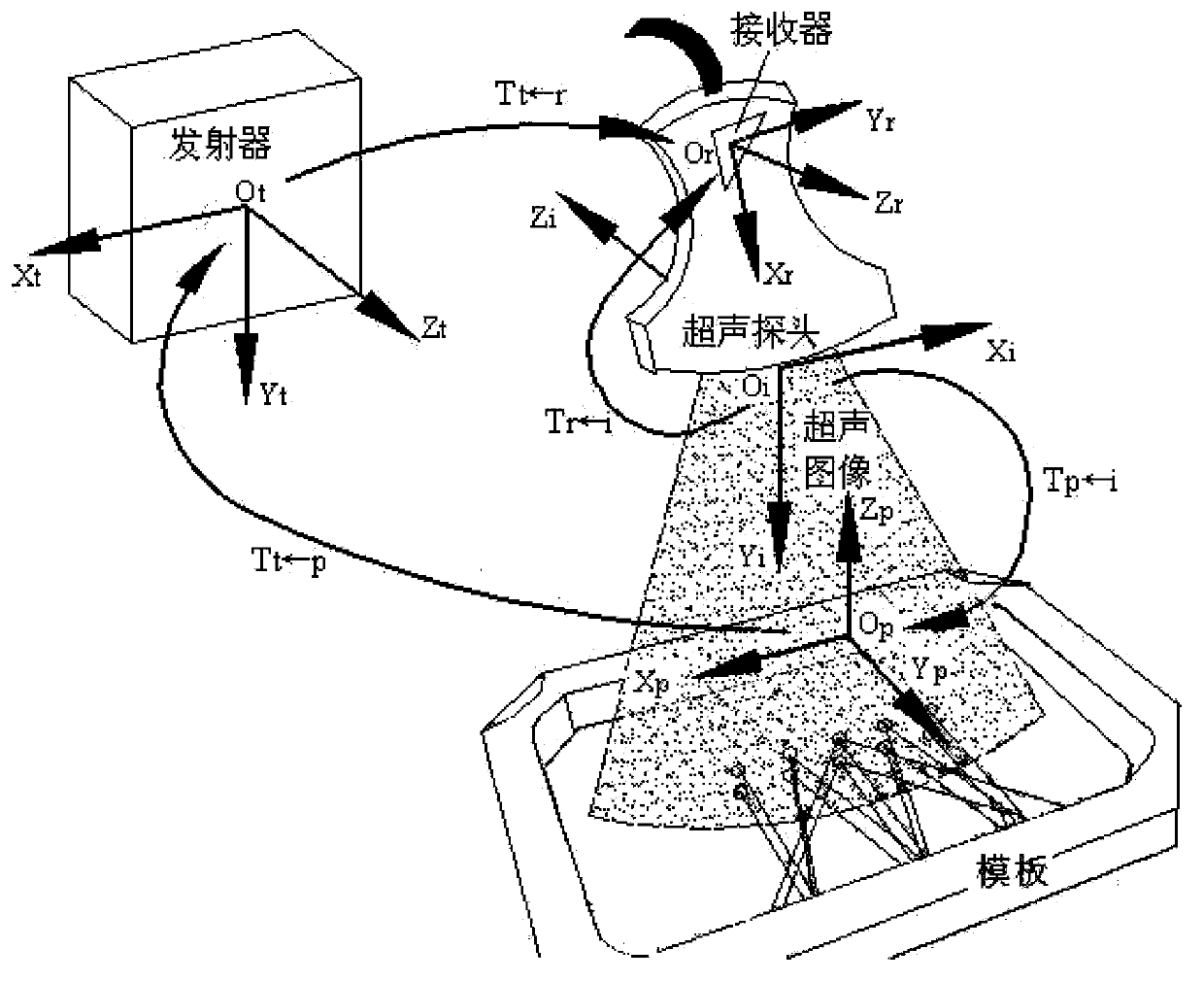

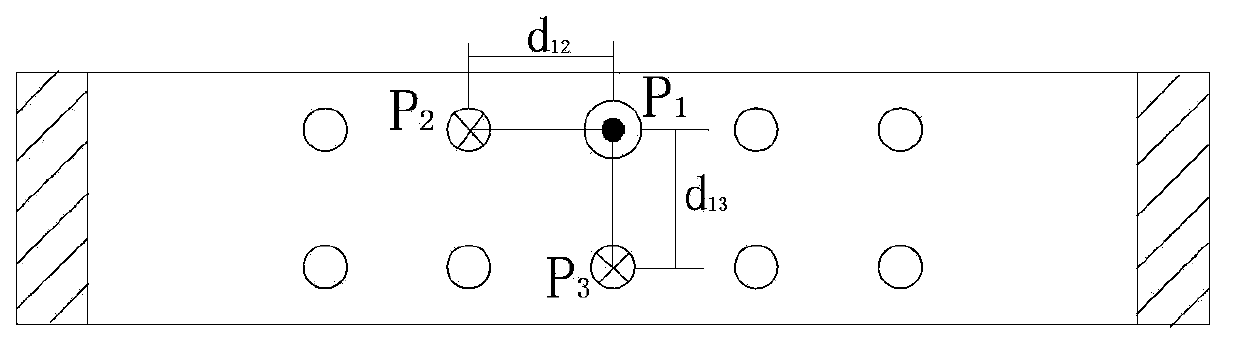

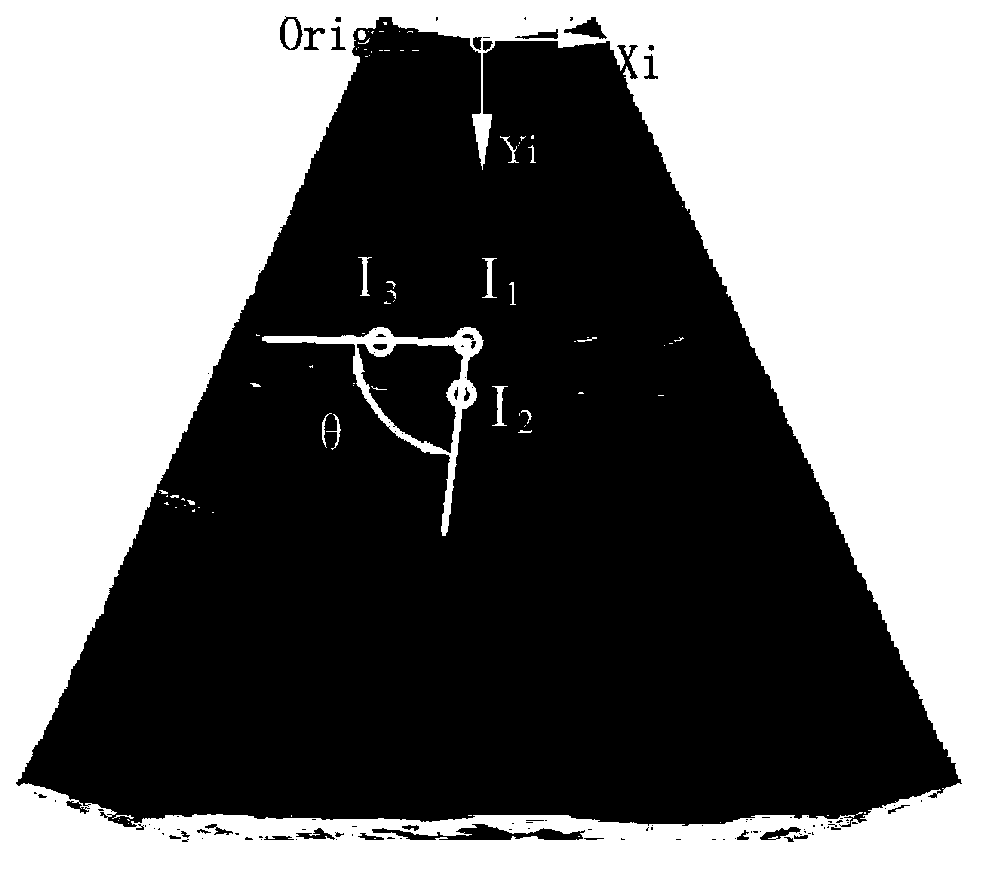

[0033] A three-dimensional calibration method for ultrasonic detection images, using NDI magnetic positioning, the positioning receiver is connected to the positioning transmitter, the method needs to be completed with a template, and the positioning receiver coordinate system Or fixed on the ultrasonic probe is calculated by the template Scanning the relationship between the image coordinate system Oi, the template is provided with two layers of mesh cotton thread, and the mesh cotton thread has n (n is 10) cotton thread intersection points on the scanning surface.

[0034] The probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com