Novel extruder

An extruder, a new type of technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of loose mold locking, waste of labor, and increased labor costs, and improve mold positioning and adjustment methods. , the effect of reducing the number of labor and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

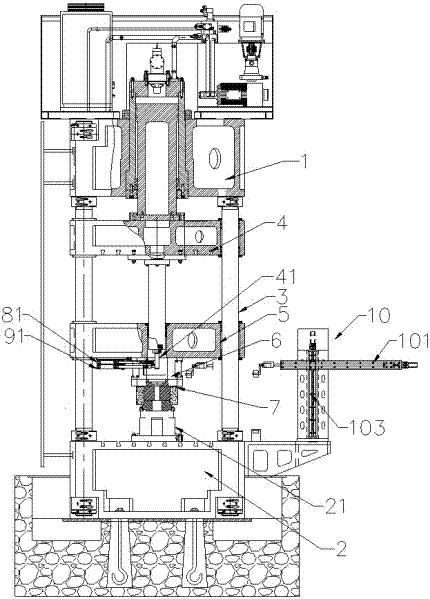

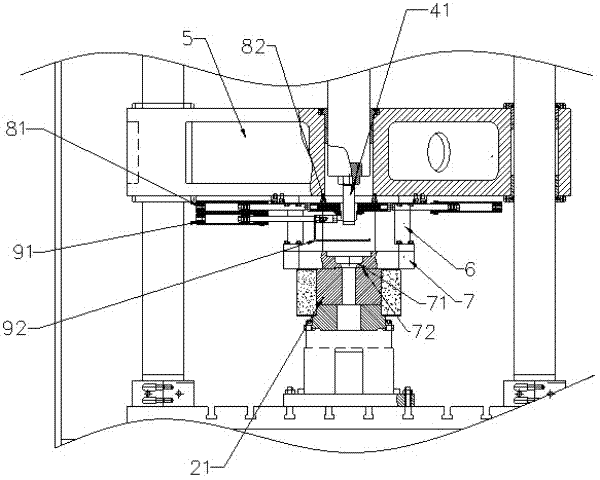

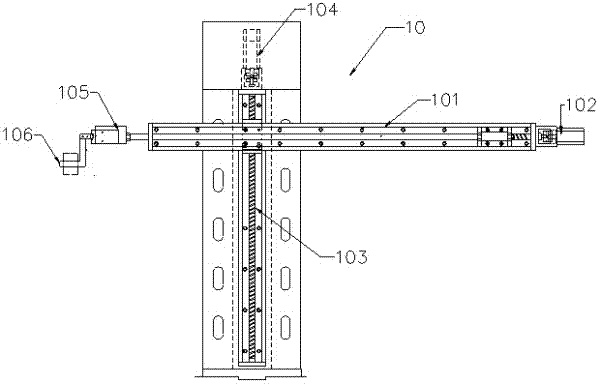

[0023] The present invention provides a new type of extrusion machine, which includes a frame, an upper slide 4 and a lower slide 5. The frame includes an upper beam 1, a lower beam 2 and a guide column 3. The guide column 3 is fixed between the upper beam 1 and the lower beam 2. In the present embodiment, there are four guide columns 3, which are respectively arranged on the four corners of the upper beam 1 and the lower beam 2, and the upper slide plate 4 and the lower slide plate 5 are slidably arranged on the guide column 3, and the upper slide plate 4 It is arranged above the lower plate 5, wherein the slidable fit is a shaft-hole fit, the cross-section of the guide post 3 is circular, and guide holes are provided at the positions corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com