Method for casting water cooling motor shell

A technology of water-cooled motors and casings, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. The effect of delivering high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

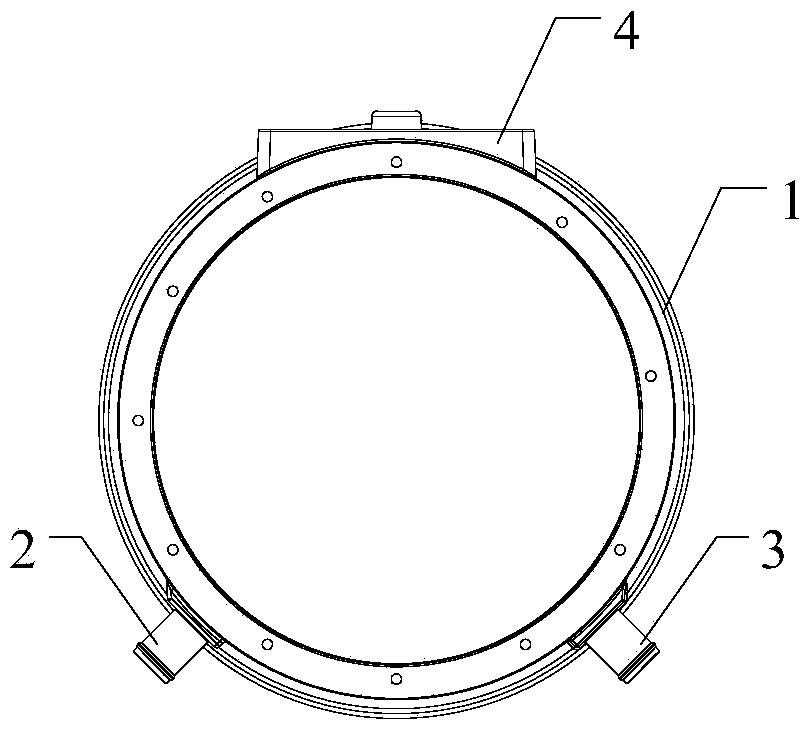

[0021] The invention provides a casting method of a motor casing with a spiral water channel, which uses a sand mold to form a water channel structure, and adopts gravity casting to realize that metal liquid such as aluminum alloy solution is injected into the mold under the action of gravity. The specific method is as follows:

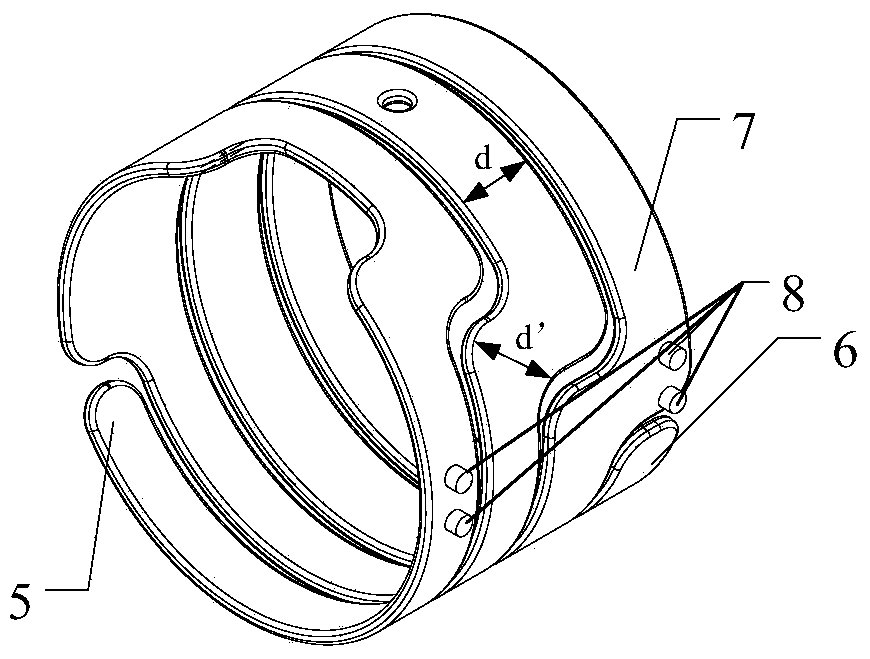

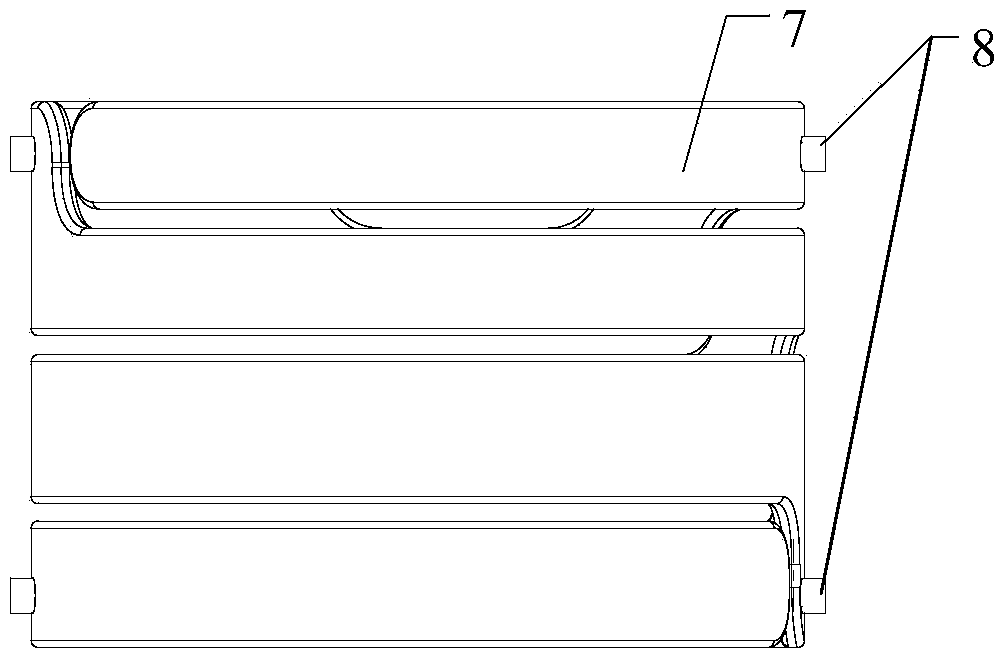

[0022] Making sand core: according to the structure of the water channel of the casing, such as figure 2 For the sand core shown, mix more than two types of coated sand with appropriate amount of phenolic resin, and blow the mixture of sand grains and phenolic resin into the sand core mold with compressed air through the core shooter. At this time, the preheating temperature of the sand core mold is 250°C. Heat and hold pressure for 20 minutes under a certain pressure, and after the mold is opened, a sand core with a certain strength and meeting the structural size requirements can be obtained. The sand core is required to have a certain strength a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com