Production system and production technology for pressure casting

A production system and production process technology, applied in manufacturing tools, foundry workshops, foundry equipment, etc., can solve the problems of inconvenient operation, low production efficiency, and high difficulty in operation, so as to reduce production costs, improve production efficiency, and avoid manual operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

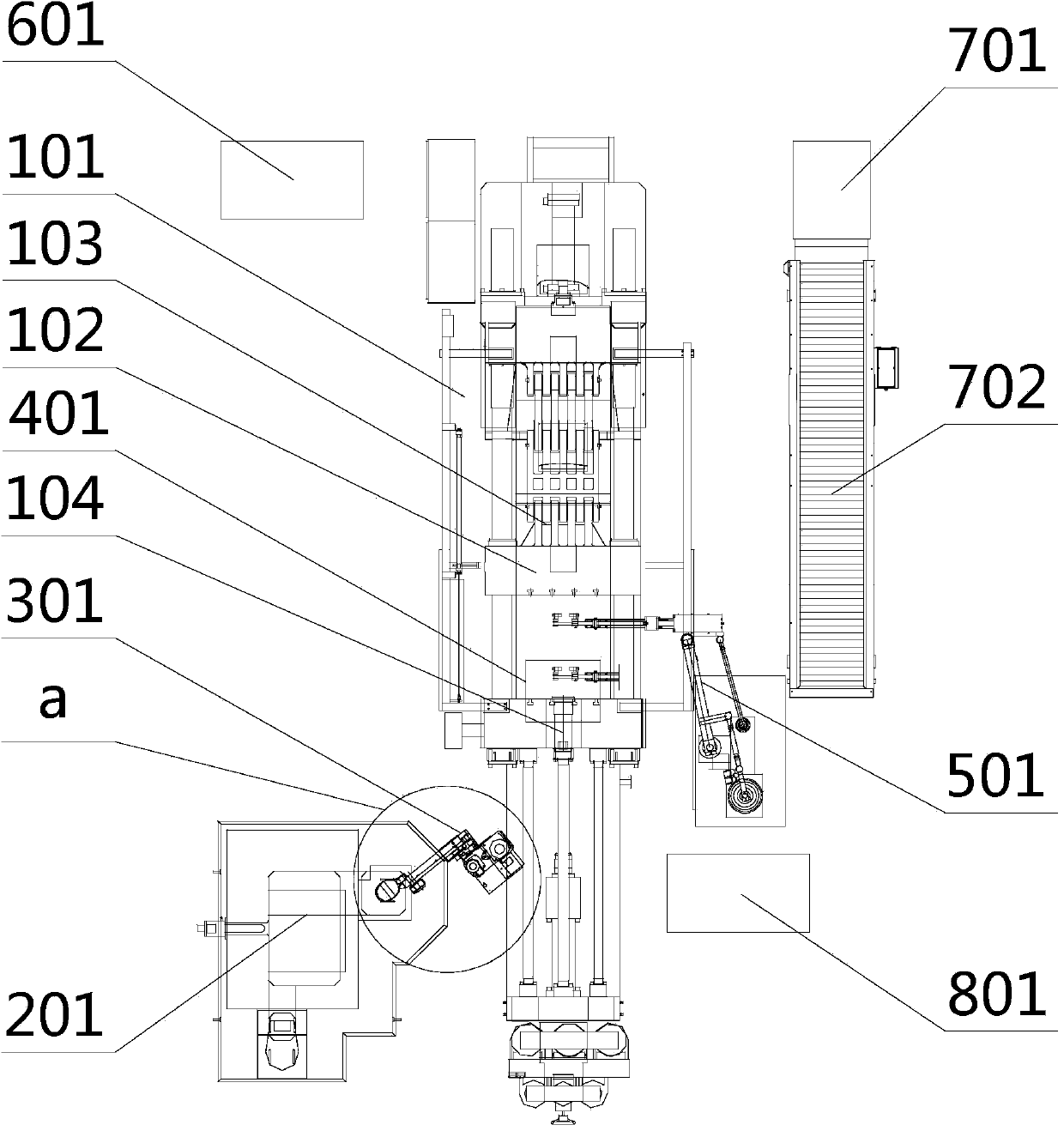

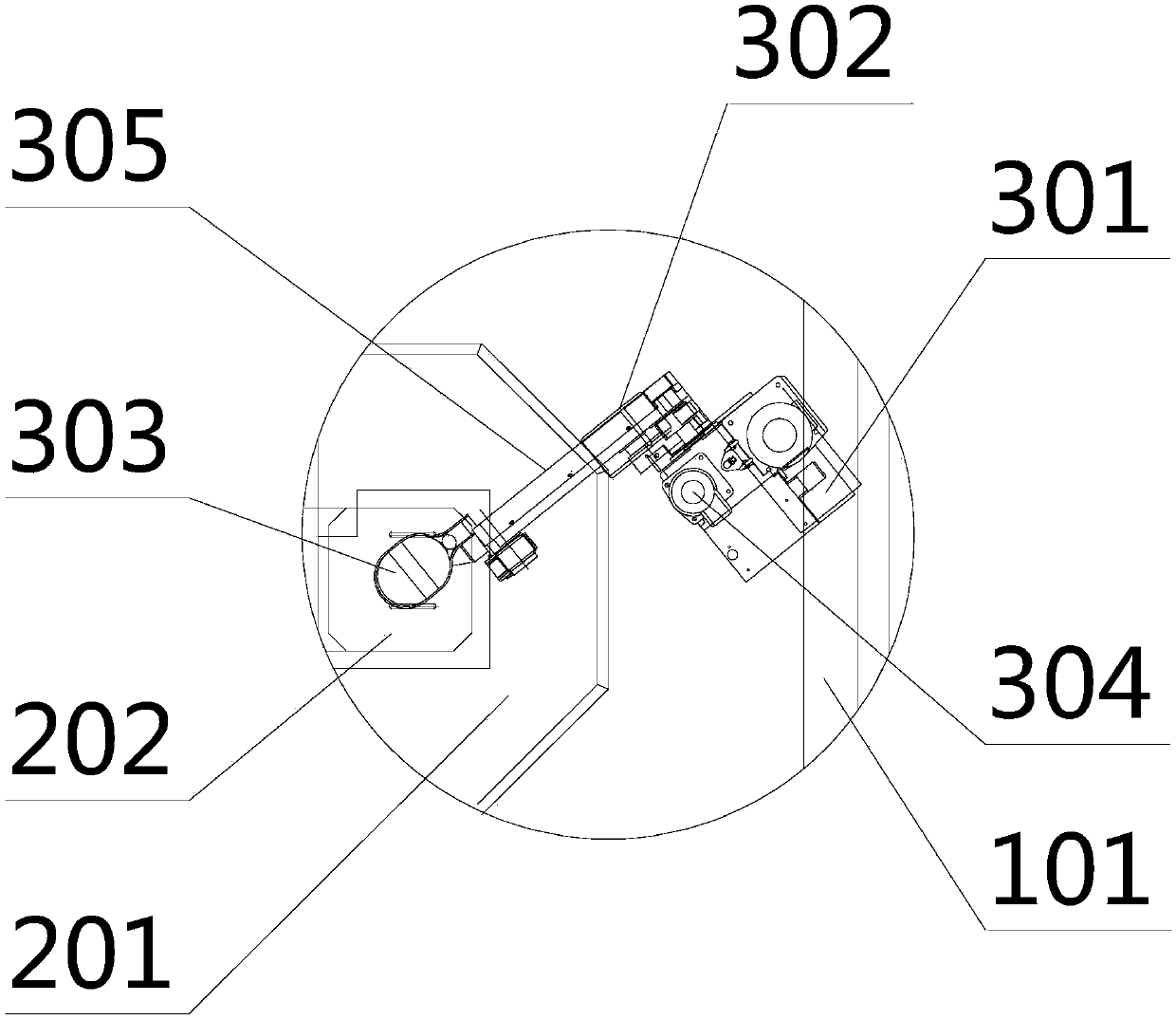

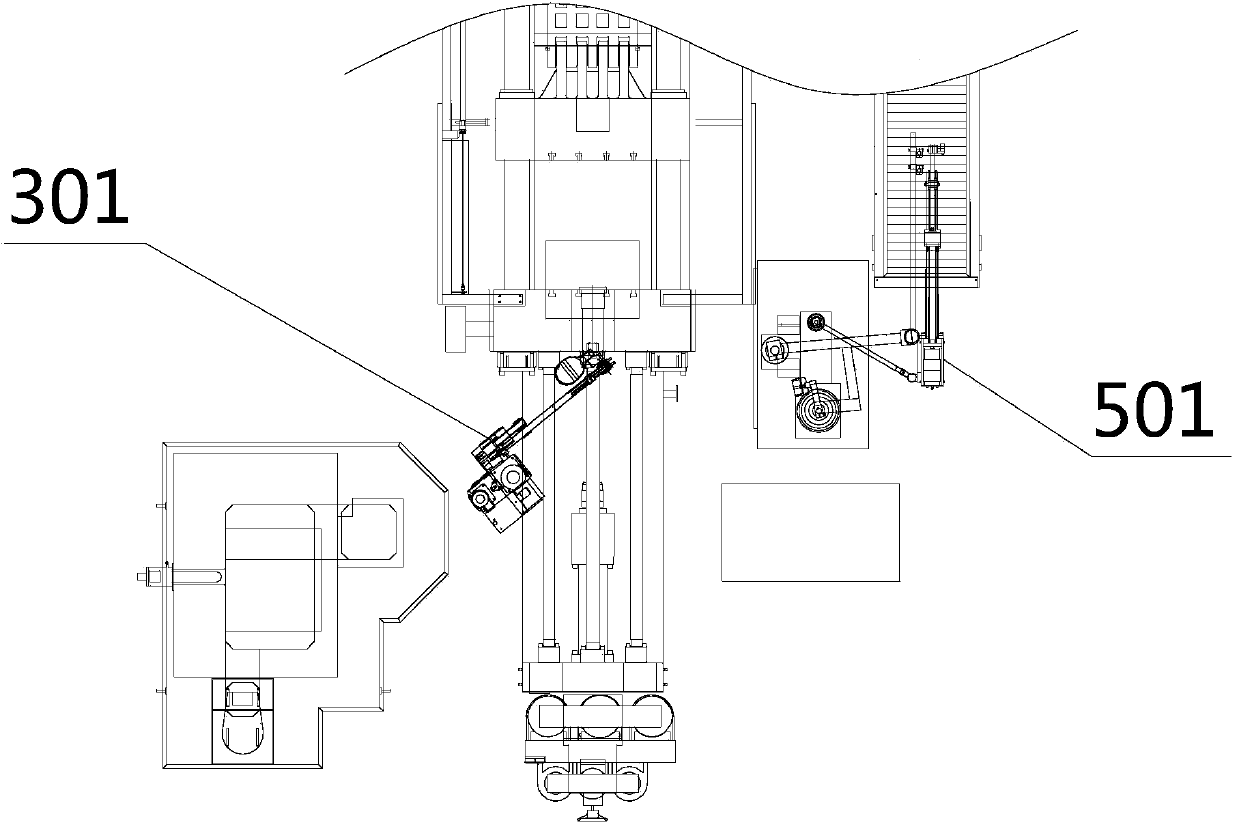

[0035] figure 1 The structure of the die casting production system provided by the embodiment of the present invention is shown; please refer to figure 1 , the embodiment of the present invention provides a die casting production system, the die casting production system includes: a die casting machine 101, preferably an automatic cold chamber horizontal die casting machine 101, the die casting machine 101 includes a die casting mold 102, a mold clamping mechanism 103 and a die casting machine 101 Injection mechanism 104; holding furnace 201 for melting and heat preservation of metal raw materials; automatic soup feeder 301 for adding molten metal in holding furnace 201 to injection mechanism 104; for spraying die-casting mold 102 The spraying machine 401, the spraying machine 401 is arranged on the top of the die-casting mold 102; the pick-up manipulator 501 for clamping and placing the die-casting, the pick-up manipulator 501 is arranged on one side of the die-casting mold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com