Air-swing self-circulating denitrification reactor

A reactor and self-circulation technology, applied in the field of biological denitrification reactors, can solve problems such as difficult regulation and nitrite accumulation, and achieve the effects of improving volumetric denitrification efficiency, strengthening biological denitrification, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

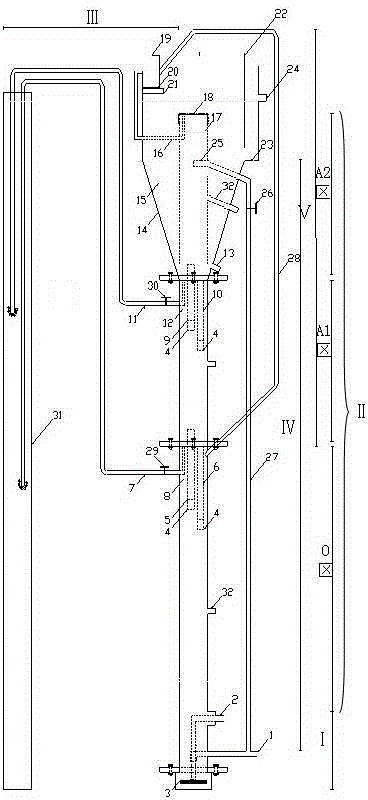

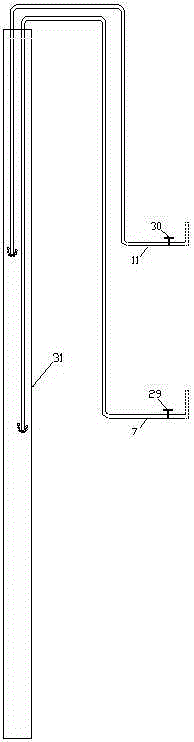

[0023] Such as figure 1 As shown, an air-swing self-circulation denitrification reactor: the reactor body is equipped with water distribution area I, reaction area II, separation area III, circulation area IV and air-swing area V;

[0024] The water distribution area I is located at the lower part of the reactor body, and is composed of the water inlet pipe 1, the air inlet pipe 2 and the aeration head 3. There is a water inlet pipe 1;

[0025] The reaction zone II is located in the middle of the reactor body, and consists of the first aerobic zone, the second anaerobic zone and the third anaerobic zone from bottom to top to form a three-stage reaction system. The first aerobic zone is the O zone. , the second-level anaerobic zone is the A1 zone, and the third-level anaerobic zone is the A2 zone; the top of the O-zone is equipped with an O-zone upper diversion pipe 5, an O-zone lower diversion pipe 6, an O-zone release pipe 7, and an O-zone set Air chamber 8; the top of A1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com