Method for improving coercive force of spinelle iron-cobalt ferrite CoFe2O4

A technology of cobalt ferrite and coercive force, which is applied in the field of ferrite material preparation, can solve problems such as coercive force not involved in ferrite, achieve lower raw material prices, fine and uniform powder, lower sintering temperature and energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

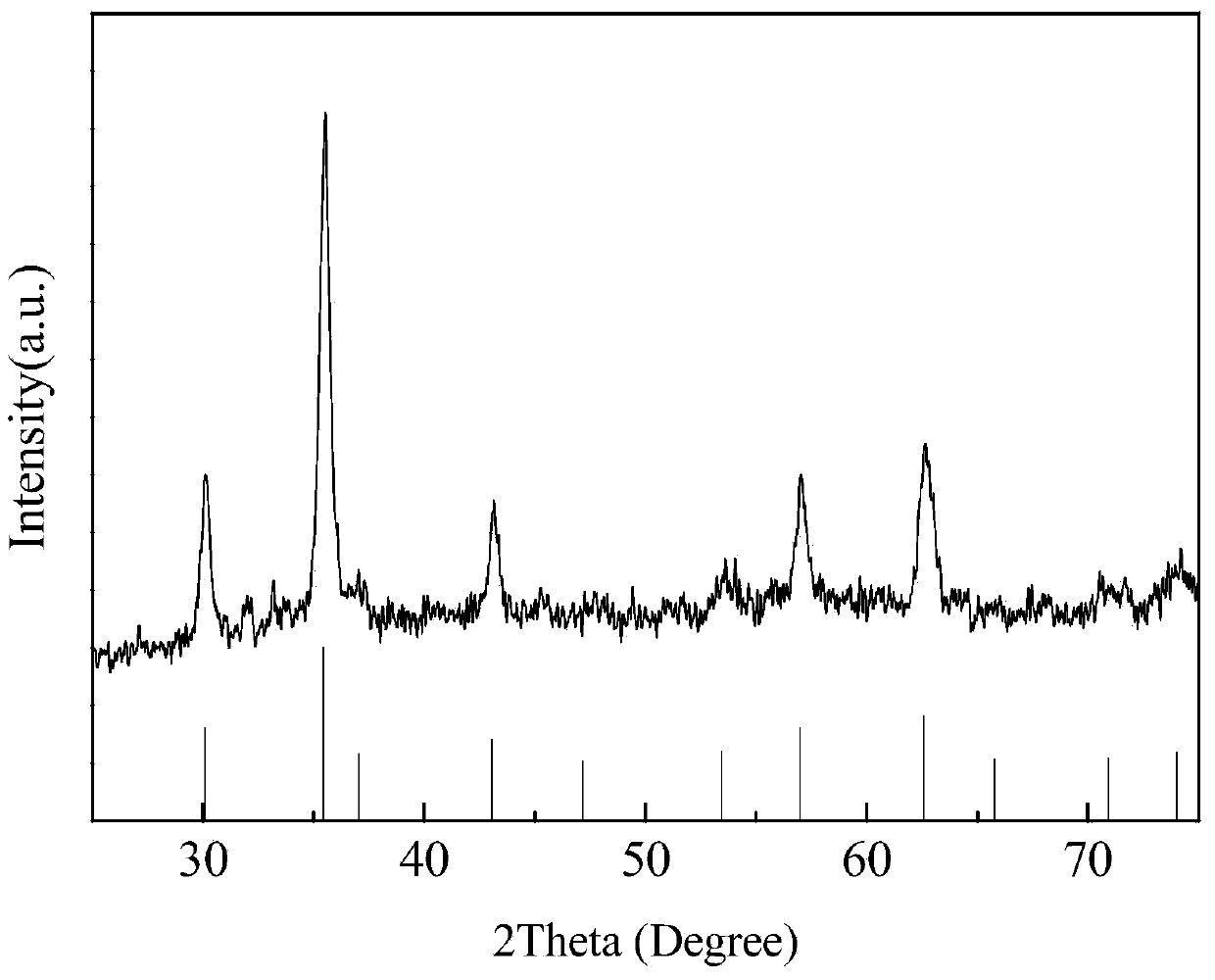

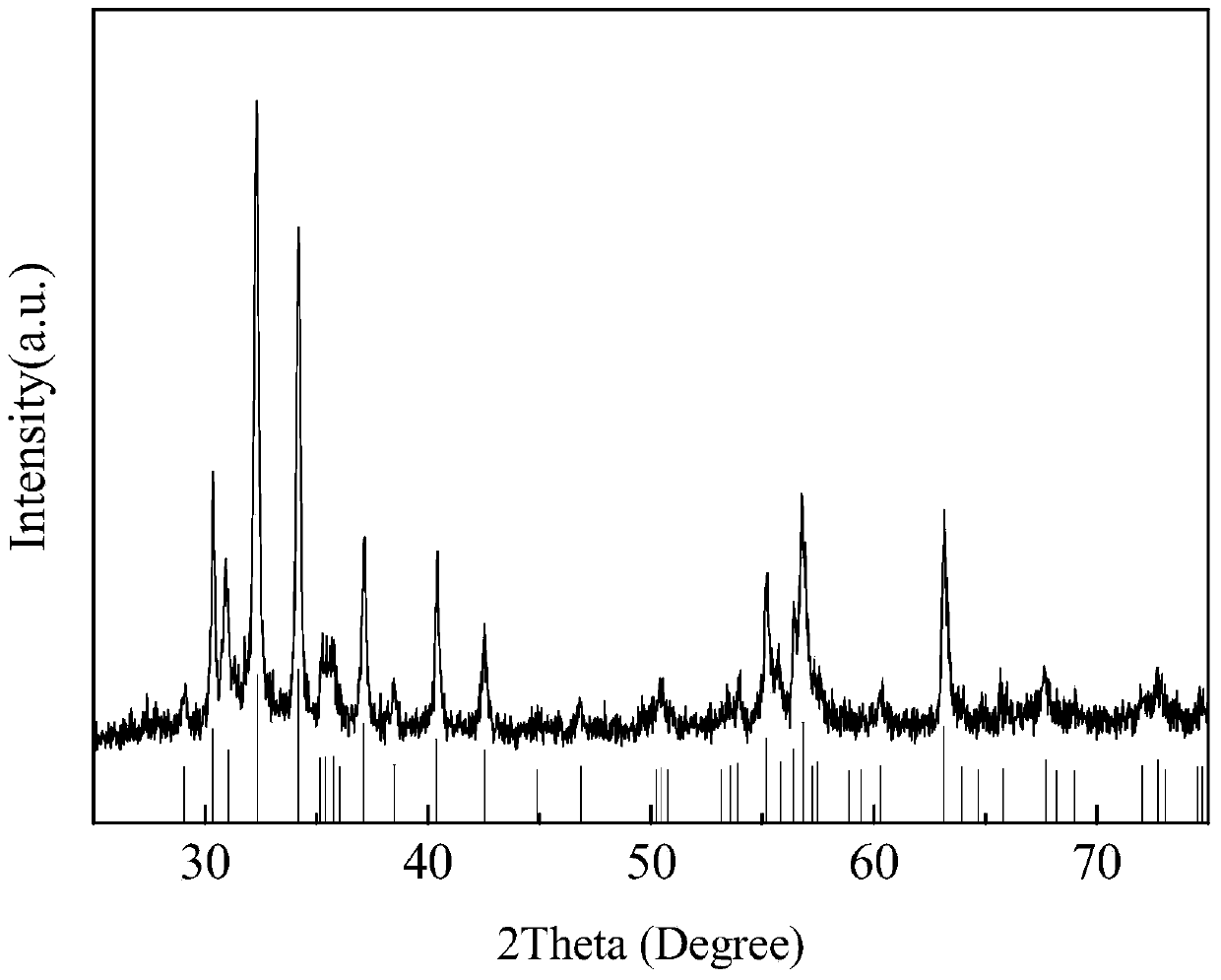

[0027] 1) Preparation of SrFe 12 o 19 Powder: to analyze pure nitrate (Sr(NO 3 ) 2 , Fe(NO 3 ) 3 ) as raw material to prepare 2mmol of SrFe 12 o 19 Powder, the molar ratio of Fe and Sr in the raw material is 4:1, and Sr(NO 3 ) 2 2mmol, Fe(NO 3 ) 3 8mmol; according to molar ratio Proportioning required NaOH, that is, 84mmolNaOH is required. The nitrate raw material was dissolved in 45 ml deionized water, and the NaOH was dissolved in 30 ml deionized water. Then, NaOH solution was added dropwise to the mixed nitrate solution while stirring to precipitate metal ions, and the precipitate and precipitate were transferred into a 100ml hydrothermal reaction kettle for hydrothermal reaction, and the reaction temperature condition was 220°C×5h. The powder obtained after the reaction was washed 3 times and 2 times with deionized water and absolute ethanol, respectively. In order to ensure the purity of the phase, the obtained SrFe 12 o 19 The ferrite powder was washed on...

Embodiment 2

[0032] CoFe 2 o 4 and SrFe 12 o 19 The preparation method of nanopowder is the same as embodiment 1, in CoFe 2 o 4 The powder is mixed with SrFe according to the mass ratio of 10% 12 o 19 Powder, mixed evenly, pressed into tablets, sintered at 900°C for 2 hours to obtain CoFe with increased coercive force 2 o 4 .

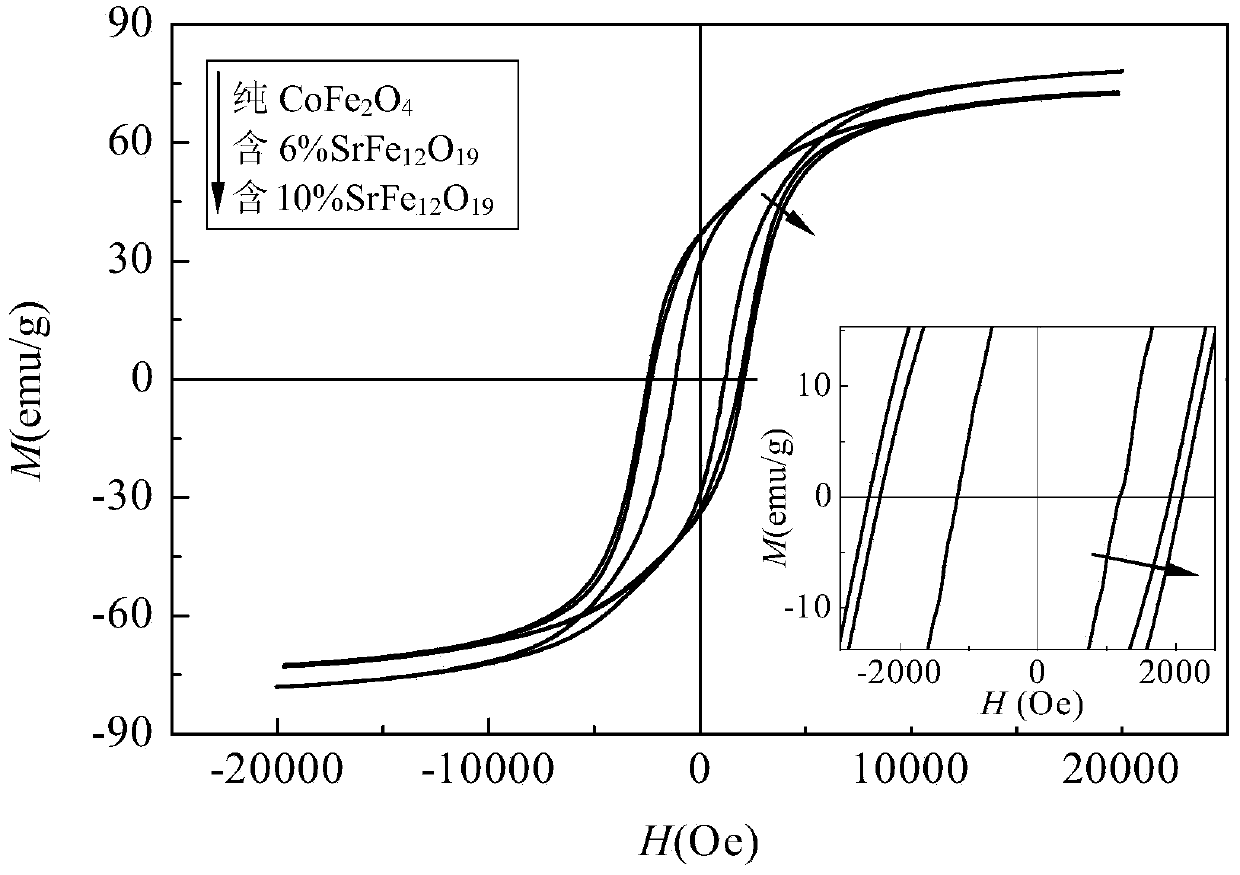

[0033] The resulting CoFe with enhanced coercivity 2 o 4 The room temperature hysteresis loop of the sample is shown in image 3 middle.

Embodiment 3

[0035] CoFe 2 o 4 and SrFe 12 o 19 The preparation method of nanopowder is the same as embodiment 1, in CoFe 2 o 4 The powder is mixed with SrFe according to the mass ratio of 6% 12 o 19 Powder, mixed evenly, pressed into tablets, sintered at 700°C for 2 hours to obtain CoFe with increased coercive force 2 o 4 .

[0036] The resulting CoFe with enhanced coercivity 2 o 4 The room temperature hysteresis loop of the sample is shown in Figure 4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com