Diesel oil additive

An additive and diesel technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., to achieve the effects of simple production process, good use effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

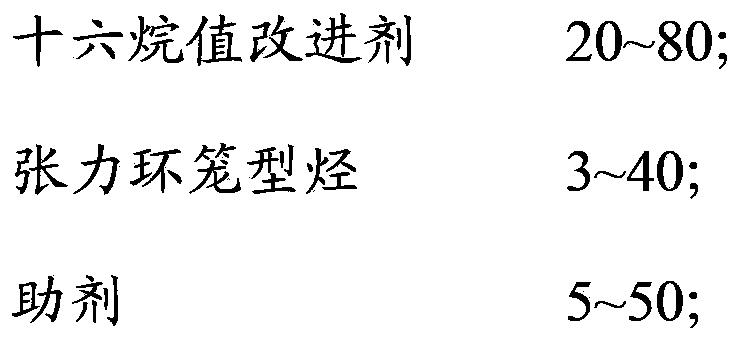

Method used

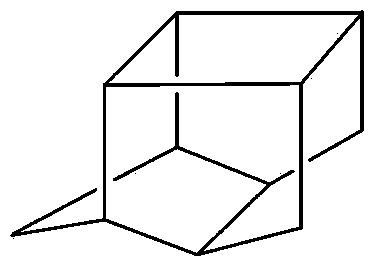

Image

Examples

Embodiment 1

[0026] 40 parts of isooctyl nitrate, 10 parts of PCU, 15 parts of polyisobutylene succinimide, 15 parts of polyisobutylene, 10 parts of 2,6-di-tert-butyl-p-cresol, 10 parts of aviation kerosene. Add PCU, polyisobutylene succinimide, polyisobutylene, 2,6-di-tert-butyl-p-cresol and aviation kerosene directly into isooctyl nitrate, stir at normal temperature and normal pressure, and mix evenly.

Embodiment 2

[0028] 80 parts of amyl nitrate, 4 parts of PCU, 12 parts of polyisobutylene succinimide, 4 parts of cerium naphthenate. Add PCU, polyisobutylene succinimide, and cerium naphthenate directly into amyl nitrate, stir under normal temperature and pressure, and mix evenly.

Embodiment 3

[0030] 55 parts of isooctyl nitrate, 40 parts of PCU, 5 parts of aviation kerosene, directly add PCU and aviation kerosene into isooctyl nitrate, mix and stir evenly under normal temperature and normal pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com