Method for enzymatic liquefaction of high-concentration corn starch

A cornstarch and high-concentration technology, applied in the direction of fermentation, etc., can solve the problems of low initial concentration of starch milk, large water consumption, and large steam consumption, and achieve the effects of easy operation, reduced energy consumption, and reduced steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

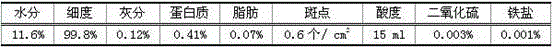

Image

Examples

Embodiment 1

[0019] Take 100 kg of raw starch, add 176.8 liters of warm water adjusted in advance at 40°C, and prepare 50% starch milk in the mixing tank. If the water temperature is too high, the starch will easily gelatinize, and if the water temperature is too low, the starch will not be easily mixed. , so warm water is required for pulping, then adjust the pH value to 5.6 with dilute hydrochloric acid (chemically pure) and sodium hydroxide (chemically pure) solutions, and add starch at a rate of 0.4 liter of high-temperature-resistant α-amylase per ton of starch (dry basis) Enzyme 35.4ml, then pump the starch milk from the mixing tank to the heat preservation liquefaction tank, heat it with a steam jacket, stir while raising the temperature until the temperature reaches 80°C, stop stirring, keep it warm for 30 minutes, and then (Dry basis) add 0.2 liter of high temperature resistant α-amylase to the ratio of adding 17.7ml of high temperature resistant α-amylase, use a jet liquefier for ...

Embodiment 2

[0021] Take 100 kg of raw starch and add it to 176.8 liters of warm water at 45°C to prepare 50% starch milk, then adjust the pH value to 5.6 ( Optimum pH value of high temperature-resistant amylase), according to the ratio of 0.45 liters of high-temperature resistant α-amylase per ton of starch (dry basis), add 39.8ml of amylase, then pump the feed liquid into the heat preservation liquefaction tank, and stir while heating Stop stirring when the temperature reaches 83°C, keep it warm for 35 minutes, then add 22.1ml of high-temperature-resistant α-amylase according to the ratio of 0.25 liters of high-temperature-resistant α-amylase per ton of starch (dry basis), and use a jet liquefier for jet liquefaction. The temperature was controlled at 105°C, and then the flash temperature was lowered to 90°C. After the liquefied liquid was kept and stirred in the liquefied laminar flow tank for 55 minutes, the DE value was detected by the film reagent method to be 16.8%, and the iodine te...

Embodiment 3

[0023] Take 100 kg of raw starch and add it to 176.8 liters of warm water at 50°C to prepare 50% starch milk, then adjust the pH value to 5.6 ( Optimum pH value of high-temperature-resistant amylase), add 44.2ml of amylase at the rate of 0.5 liter of high-temperature-resistant α-amylase per ton of starch (dry basis), and then pump the starch milk from the mixing tank to heat preservation liquefaction In the tank, heat with a steam jacket, stir while raising the temperature until the temperature reaches 85°C, stop stirring, keep it warm for 40 minutes, and then add 0.3 liters of high-temperature-resistant α-amylase per ton of starch (dry basis) to add high-temperature-resistant α Amylase 26.5ml, using jet liquefier for spray liquefaction, the temperature is controlled at 105°C, and then the flash temperature is reduced to 90°C, the liquefied liquid is kept in the liquefaction laminar flow tank for 60 minutes, and the DE value is detected by the film reagent method It was 17.8%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com