A replaceable energy-dissipating component and energy-dissipating structure at the foot of a shear wall

A shear wall and energy dissipation technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problem of low stiffness of viscous dampers or frictional energy dissipators, stiffness or bearing capacity that does not match shear walls, and shear problems. The problems such as the decrease of the rigidity of the force wall have been achieved, and the effects of good ductility, easy popularization and application, and restoration of the seismic function have been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

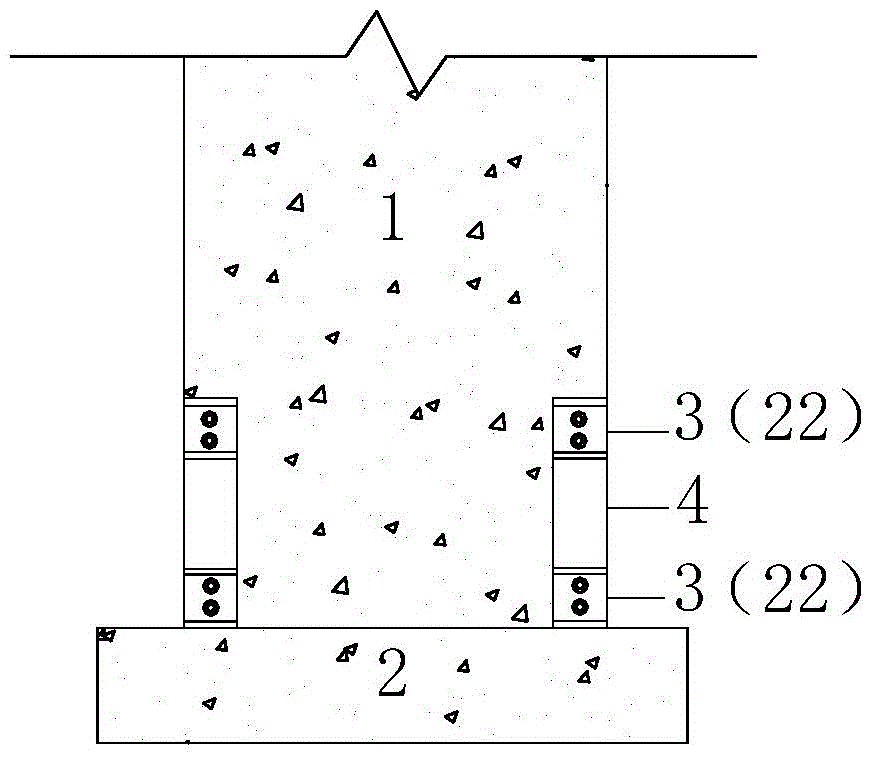

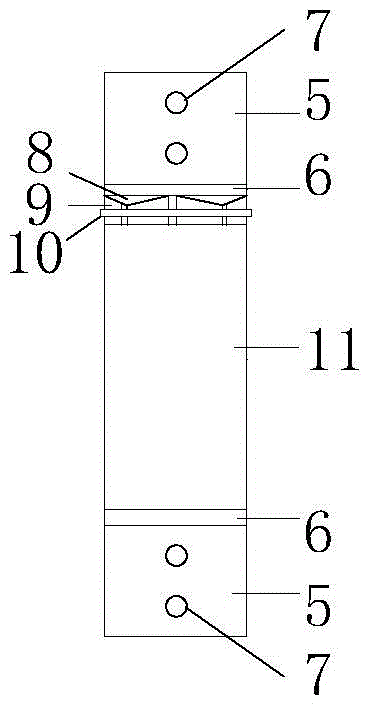

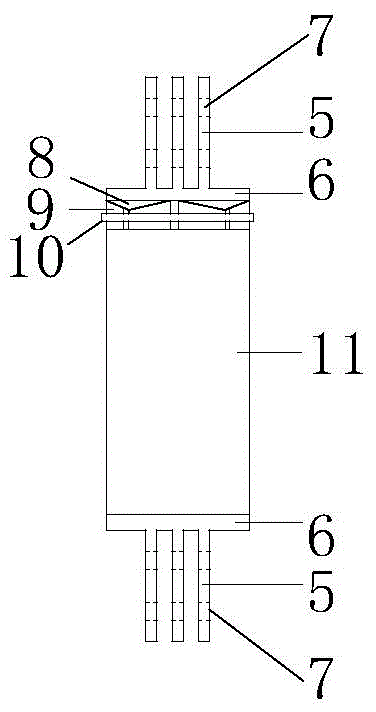

[0042] Such as Figure 1 to Figure 3 As shown, the present invention discloses a replaceable energy-dissipating component at the foot of a shear wall, which includes connecting sections 3 at the upper and lower ends and a main body section 4 in the middle.

[0043] Among them, such as Figure 2 to Figure 4As shown, the connecting sections respectively include connecting end plates 6 and energy-dissipating connectors for connecting with the shear wall. The specific structure of the energy-dissipating connectors can be set according to specific conditions. In this embodiment, the energy-dissipating connectors include The connecting guide rail 5 and the connecting guide rail bolt hole 7 are fixedly arranged on one end surface of the connecting end plate 6 , and the connecting guide rail bolt hole 7 is provided through the connecting guide rail 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com