Dual-mode silencer for internal combustion engine exhausting system

An exhaust system and muffler technology, which is applied to exhaust devices, machines/engines, gas chambers, etc., can solve the problems of maintaining low back pressure and the control signal cannot reflect the engine, so as to improve the muffler efficiency and reduce the volume of the sound cavity. The effect of small, high muffling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

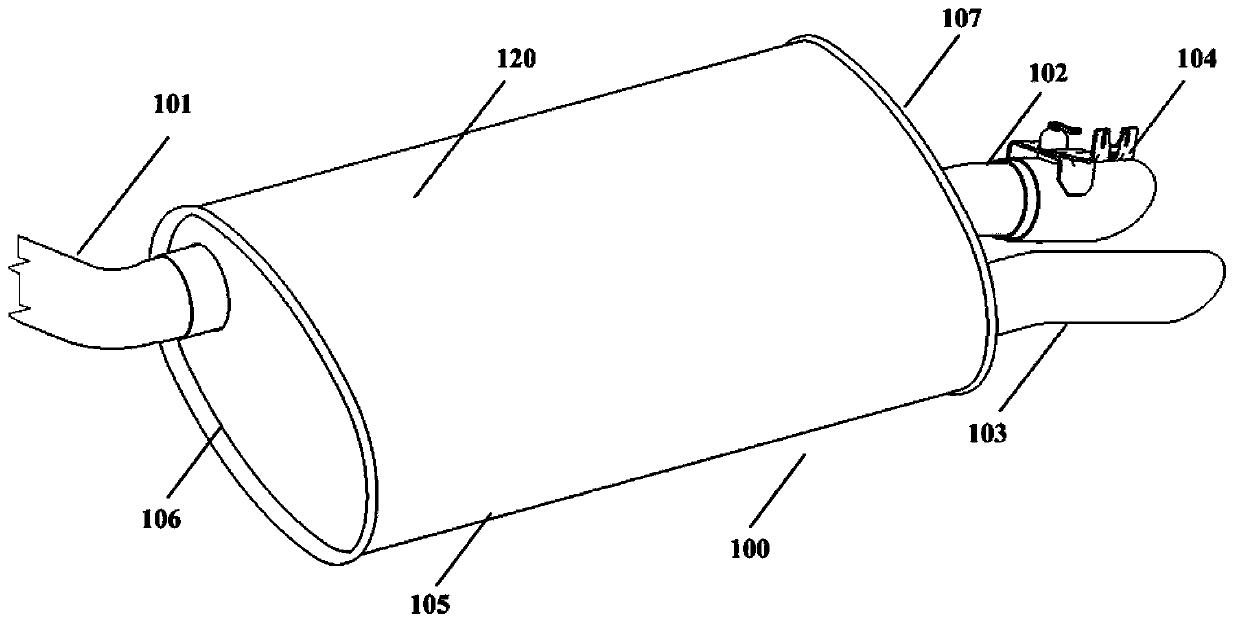

[0035] figure 1 One embodiment of the muffler of the present invention is shown. Such as figure 1 As shown, the muffler 100 has an input pipe 101 and two output pipes 102 and 103 . Inlet pipe 101 provides a connection to the engine of the vehicle to which muffler 100 is installed, for receiving exhaust gas. A control device 104 is arranged on the exhaust pipe 102 . Such as figure 1 As shown, the housing 105 is enclosed by two end caps 106 and 107 to form a muffler housing compartment 120 .

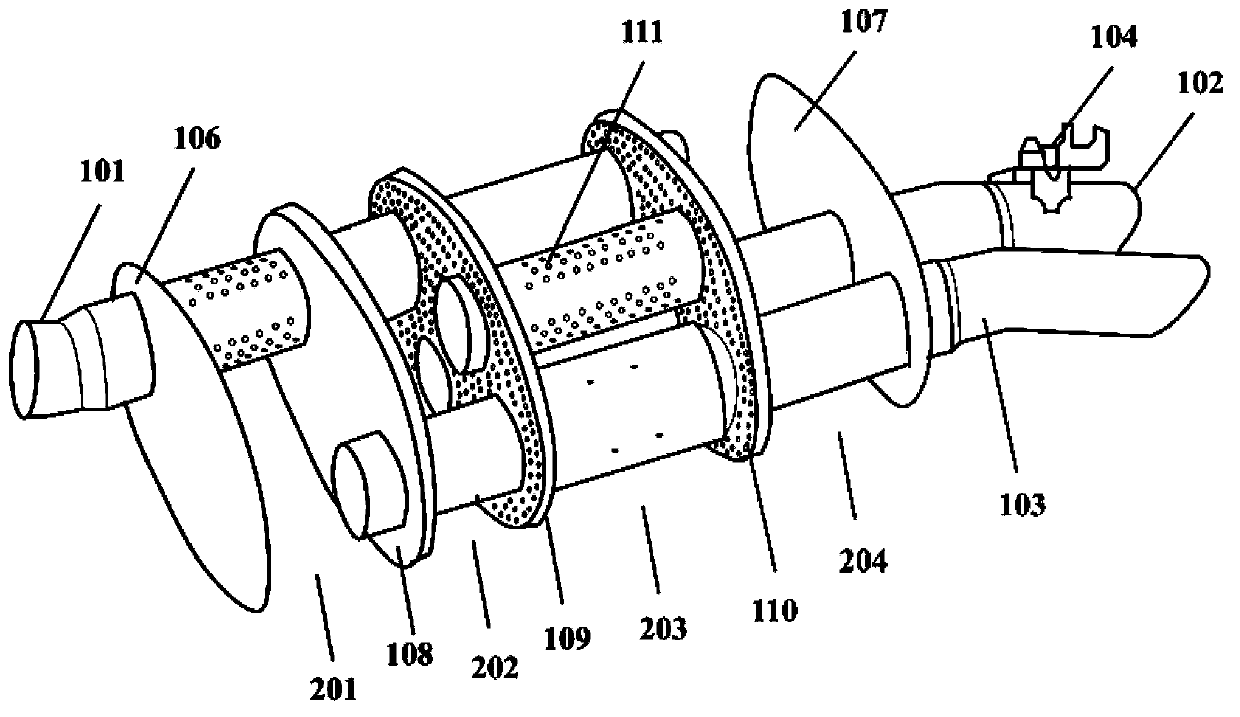

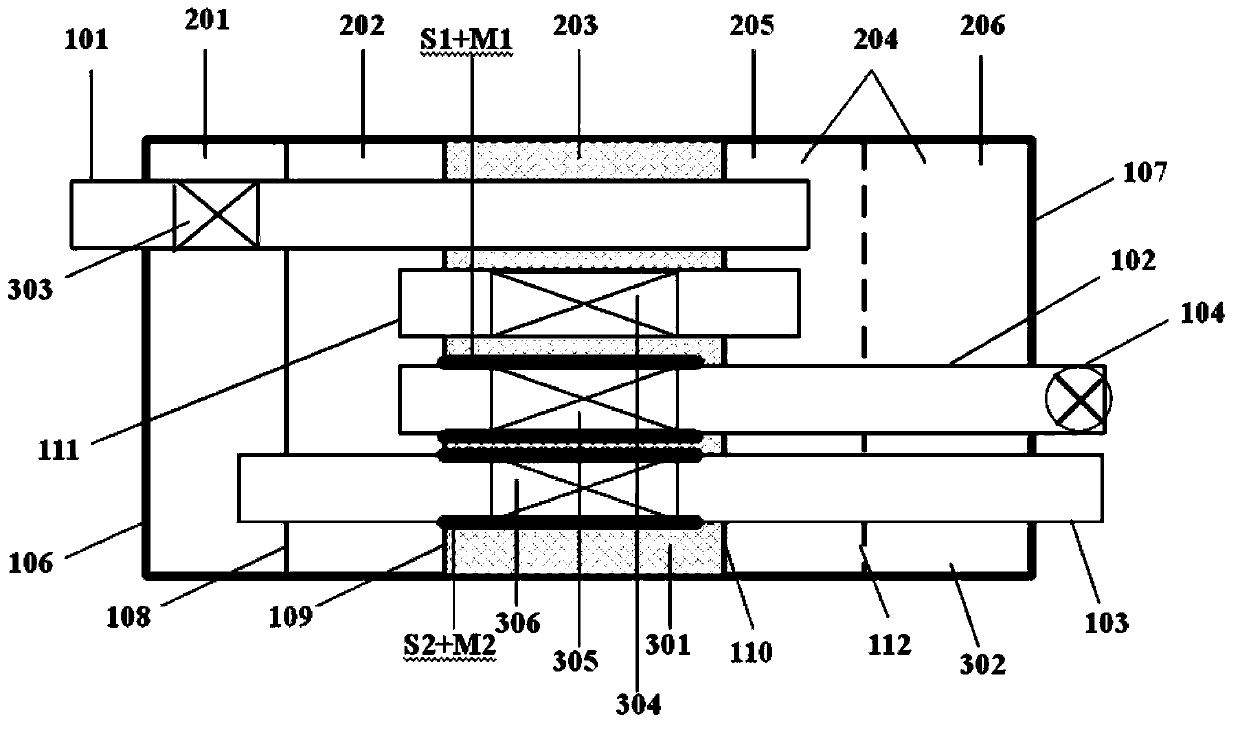

[0036] figure 2 yes figure 1 The shown muffler is a schematic perspective view of the muffler without the muffler shell and optional fibers in order to clearly show the internal structure of the muffler. Such as figure 2 As shown, the muffler has three baffles 108 , 109 and 110 . These partitions together with the two end covers 106, 107 divide the muffler housing room 120 into four chambers: between the end cover 106 and the partition 108 is the first chamber 201, between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com