Slit type air floating ball bearing

A kind of air-floating ball, slot technology, applied in the direction of bearing, shaft and bearing, mechanical equipment, etc., can solve the problems of local flow resistance increase, bearing performance influence, deterioration, etc., to achieve uniform pressure distribution, high load and stiffness, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

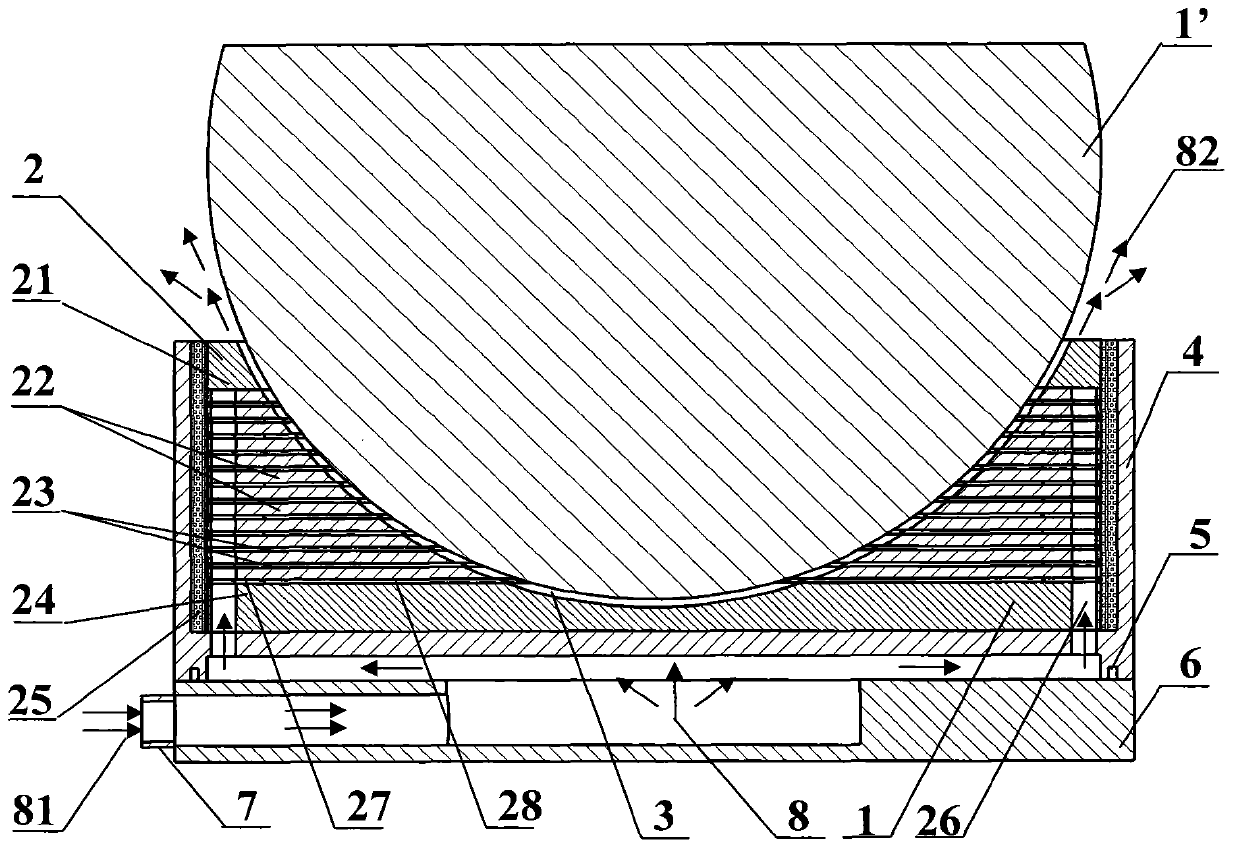

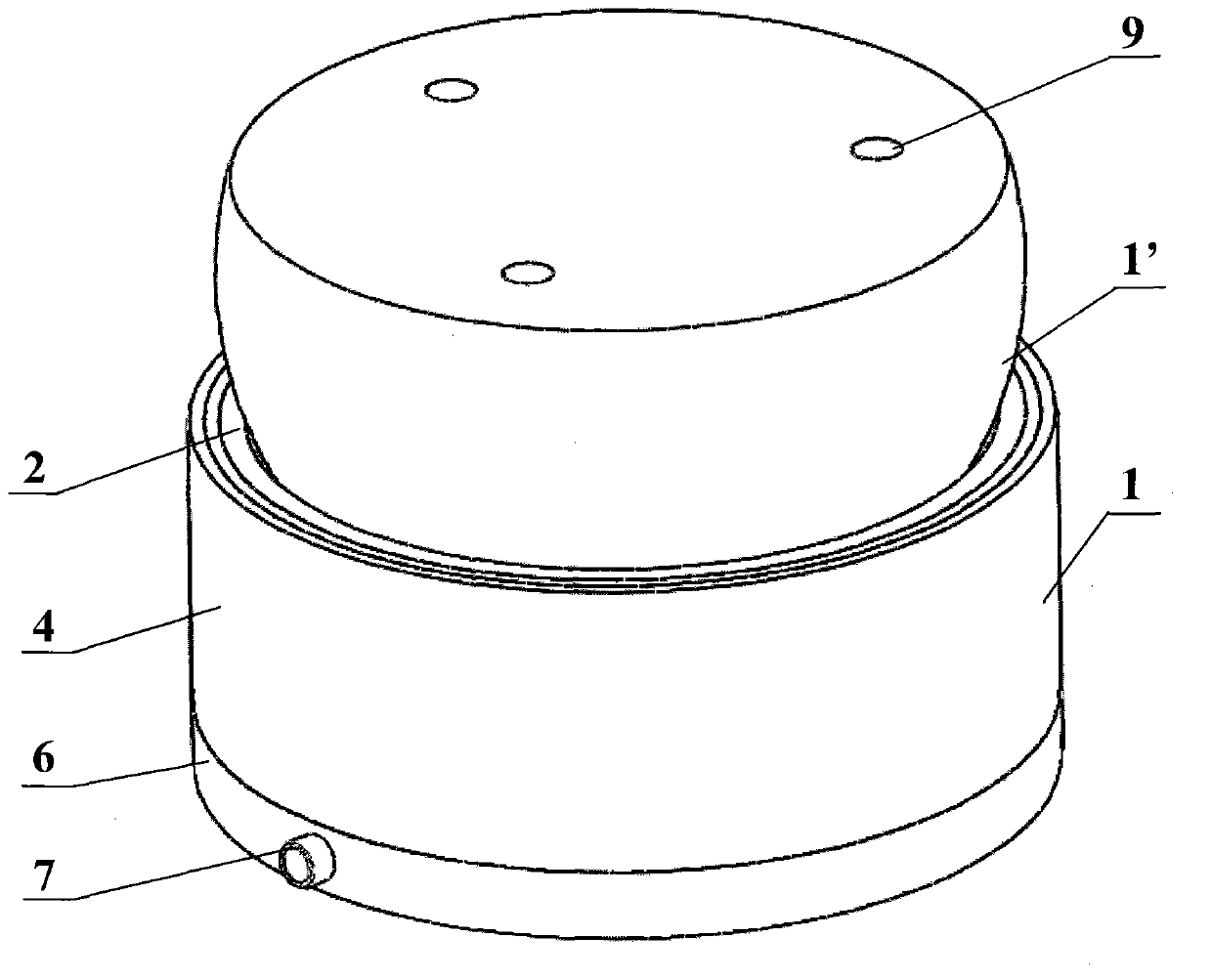

[0040] like Figure 1 to Figure 7 As shown, the slot type air bearing embodiment of the present invention mainly consists of a convex spherical rotor 1 ', a concave spherical stator 1, a stator base 6, and an air intake nozzle 7.

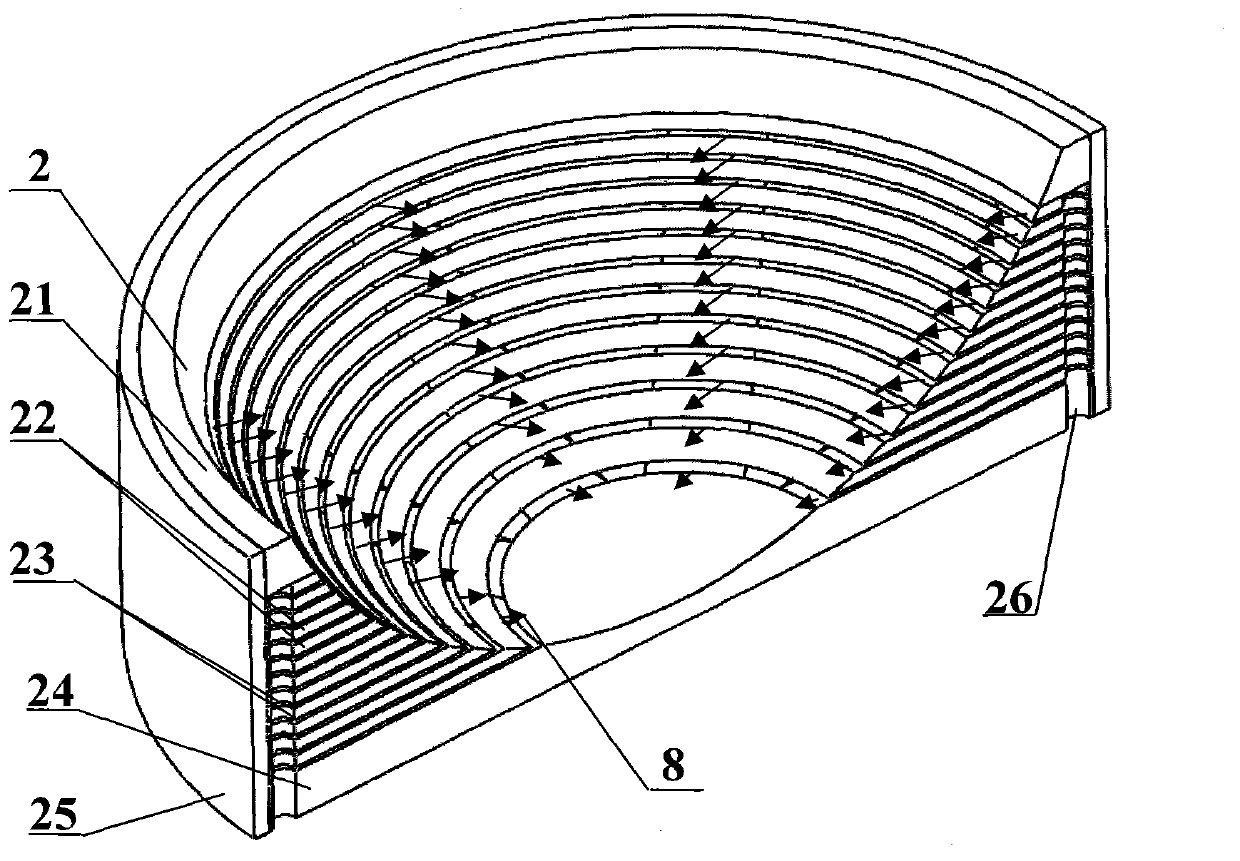

[0041] Specifically, the outer circumference of the stator base 6 of the embodiment of the slit-type air bearing ball bearing of the present invention is connected to the intake nozzle 7; the stator base 6 is terminated to the concave spherical stator 1 . The concave spherical stator 1 is composed of a stator casing 4 and a laminate structure 2 . A sealing groove 5 is provided between the concave spherical stator 1 and the stator base 6 to facilitate sealing connection. The inner wall of the concave spherical stator 1 is provided with a laminate structure 2 with multiple groups of laminates stacked at intervals and with air outlet slits. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap