Reinforced Concrete Beam Demolition Blasting Blasting Hole Charge, Blockage and Slag Pressing Structure and Demolition Blasting Method

A technology for charging reinforced concrete beams and blastholes, which is applied in blasting construction for demolition of reinforced concrete beams and in the field of blasting blasting for demolition of reinforced concrete beams. Poor and other problems, to achieve the effect of blasting safety protection, reduce the total cost, significant economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

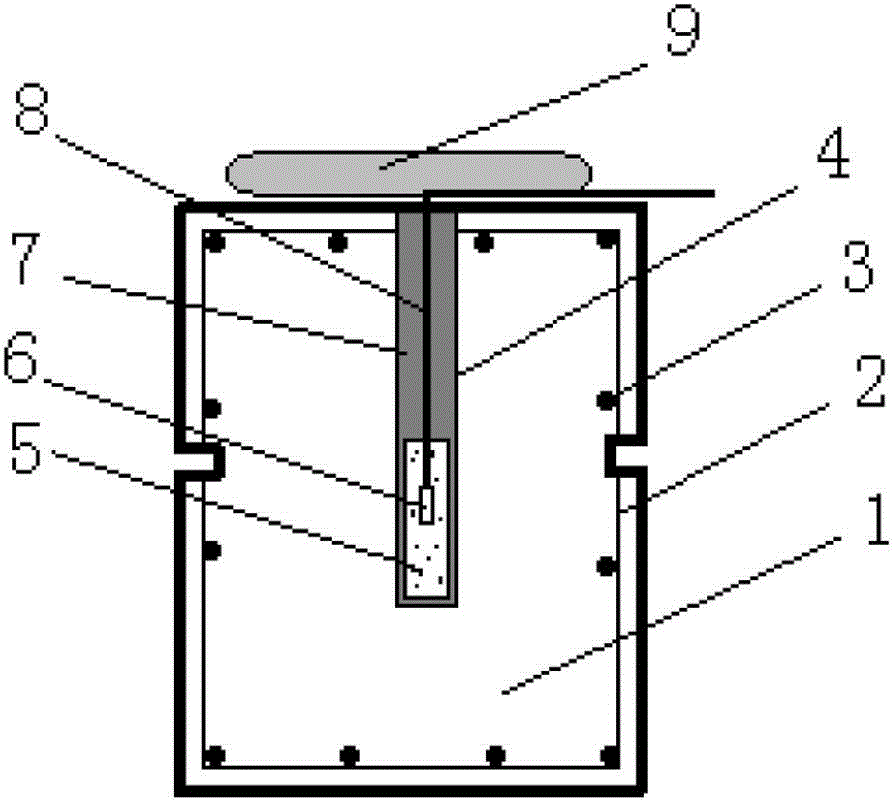

Image

Examples

Embodiment 1

[0025] Reinforced concrete beam cross-section width × height dimension is 0.6m × 0.8m, blast hole depth 0.5m (minimum resistance line 0.3m), blast hole diameter 32mm, emulsion explosive charge length 0.2m, blast hole plugging material layer depth 0.3m, and the hole spacing is 0.6m. The blast holes are pre-embedded with plastic pipes on the longitudinal centerline of the upper surface of the reinforced concrete beam. Adopt nonel and nonel delay detonator. The slag pressing water bag adopts a polyethylene film bag with a size of 0.8m×0.4m, and one water bag is used for each blast hole; when slag pressing, the center of the water bag is aligned with the blast hole, and the length direction is consistent with the longitudinal direction of the reinforced concrete beam.

[0026] The material formula (by weight) of the blast hole plugging material layer is 1 part of 801-2 type construction glue, 1 part of construction gypsum, and 1 part of tap water;

[0027] The film thickness of ...

Embodiment 2

[0038] Reinforced concrete beam cross-section width × height dimension is 1.2m × 1.4m, blast hole depth 1.0m (minimum resistance line 0.4m), blast hole diameter 32mm, emulsion explosive charge length 0.64m, blast hole plugging material layer depth 0.36m, blasthole spacing 0.7m, two rows of blastholes are symmetrically arranged on both sides of the longitudinal center line on the upper surface of the reinforced concrete beam, with a row spacing of 0.4m. Adopt nonel and nonel delay detonator. The slag pressing water bag is a polyethylene film bag with a size of 0.8m×0.4m, and one water bag is used for each blast hole; when the water bag is slag pressing, its center is aligned with the blast hole, and its length direction is consistent with the longitudinal direction of the reinforced concrete beam.

[0039] The material formula (by weight) of the blast hole plugging material layer is 1 part of 801-2 type construction glue, 1.5 parts of tap water, and 1 part of construction gypsu...

Embodiment 3

[0051] Reinforced concrete beam cross-section width × height dimension is 0.6m × 0.9m, blast hole depth 0.6m (minimum resistance line 0.3m), blast hole diameter 32mm, emulsion explosive charge length 0.27m, plugging material layer depth 0.33m , the blast hole spacing is 0.7m, and the blast holes are arranged on the center line of the upper surface of the reinforced concrete beam by pre-embedding plastic pipes. Adopt nonel and nonel delay detonator. The slag pressing water bag adopts a polyvinyl chloride film bag with a size of 0.7m×0.4m, and each blast hole uses a water bag; when slag pressing, the center of the water bag is aligned with the blast hole, and the length direction is consistent with the longitudinal direction of the beam.

[0052]The material formula (in parts by weight) of the blast hole plugging material layer is 1 part of 801-2 type construction glue, 2 parts of tap water, and 1 part of α-type hemihydrate gypsum;

[0053] The film thickness of the pressed sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com