Method for measuring cohesiveness of cement-based building mortar

A measurement method and cohesiveness technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the unfavorable development of the construction industry in the direction of energy conservation and environmental protection, the difficulty of popularizing and applying ready-mixed mortar, and the poor operability of ready-mixed mortar, etc., to achieve The effect of low detection cost, simple and practical measurement method, and easy-to-understand detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

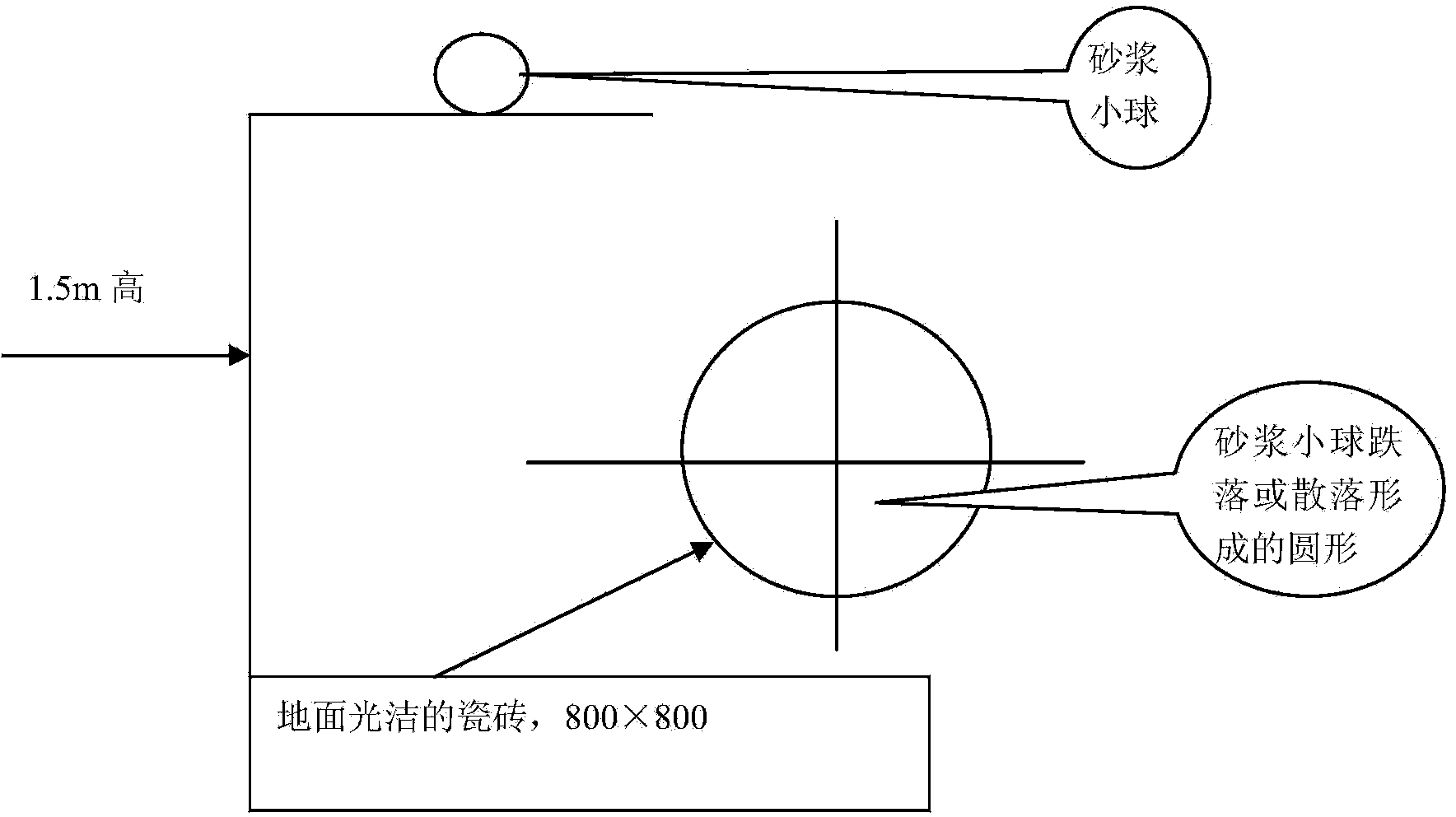

[0030] Embodiment 1 Utilizes the process of detection method of the present invention to measure cohesiveness

[0031] 1.1 Preparation of mortar

[0032] 1.1.1 When preparing mortar mixture in the laboratory, the materials used should be transported into the room 24 hours in advance. The temperature of the test chamber should be kept at (20±5)°C during mixing.

[0033] Note: When it is necessary to simulate the mortar used under the construction conditions, the temperature of the raw materials used should be consistent with that of the construction site.

[0034] 1.1.2 The raw materials used in the test should be consistent with those used on site. The machine-made sand should pass through a square hole sieve with a nominal particle size of 4.75mm in advance.

[0035] 1.1.3 When mixing mortar in the laboratory, the amount of materials should be measured by mass. Accurately weigh various materials, and its weighing accuracy: ±0.5% for cement, admixtures, admixtures, etc.; ±...

Embodiment 2

[0058] Embodiment 2 detection application example

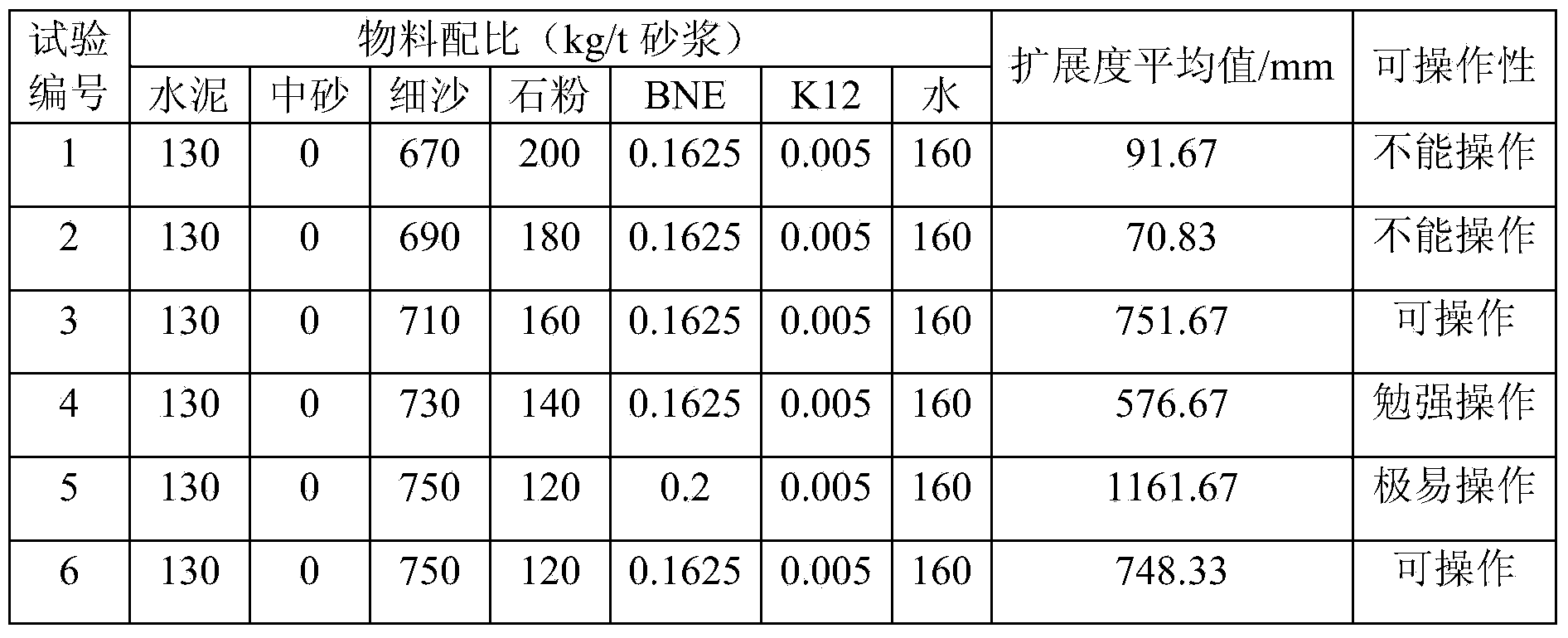

[0059] The method of Example 1 was used to detect the average value of the degree of expansion of the cement mortar obtained by preparing the following material proportions, thereby judging its cohesiveness.

[0060] Table 2 Test results of application examples

[0061]

[0062] It can be seen from the above table that the performance of cement mortar can be judged quickly by using the detection method of the present invention, which provides standards for actual production and operation, and facilitates timely improvement of material formula to cope with changes in actual production conditions.

[0063] In summary, the method of the present invention is proposed and established for the first time to evaluate the cohesion of mortar, which provides a standard support for actual production, has strong feasibility and broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com