Electrochemical NMR in situ quantitative detection electrolytic cell with grid-like working electrode structure

A working electrode and nuclear magnetic resonance technology, which is applied to the electrochemical variables of materials and the analysis of nuclear magnetic resonance, can solve the problems of easy falling off, shortening the service life of electrodes, and reducing the adhesion between electrodes and glass, so as to increase thickness and prolong Effect of service life and improvement of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

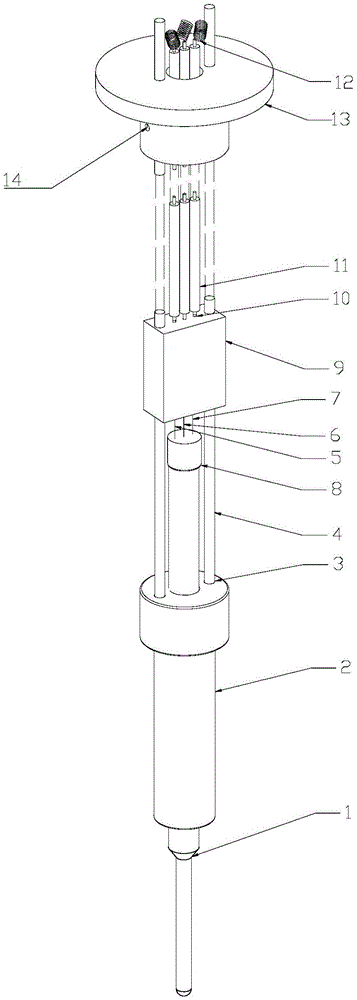

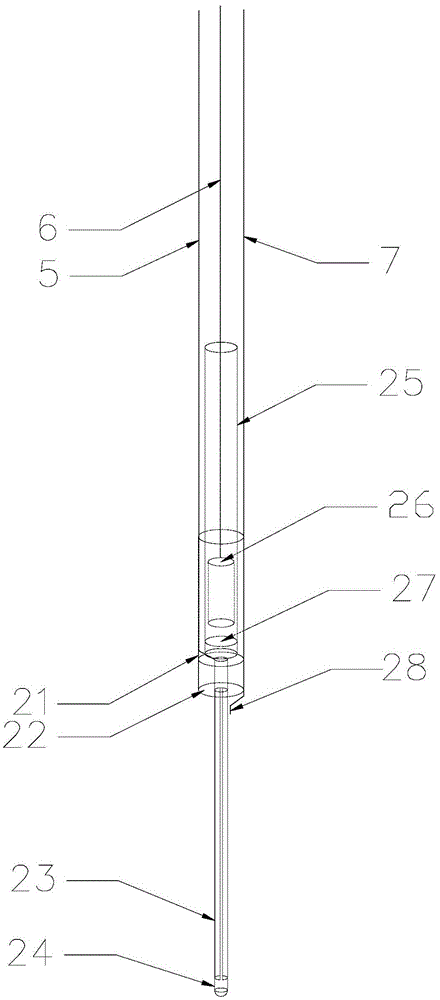

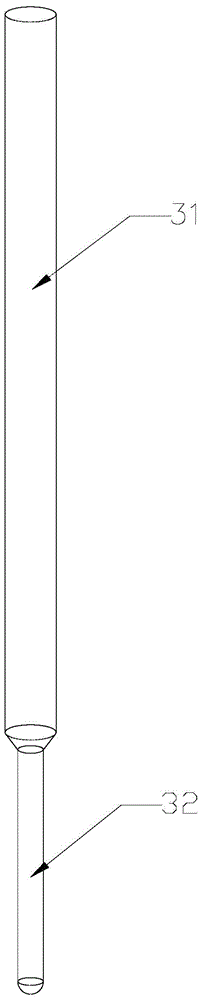

[0025] see Figure 1~6 , the embodiment of the present invention is provided with electrolytic cell body 1, sample tube rotor 2, connecting rod 4, electrode adapter plug 9, coaxial cable 11, fixed table 13, working electrode 23, auxiliary electrode 26, reference electrode 28, The first nuclear magnetic sample tube 21 , the second nuclear magnetic sample tube 24 , the third nuclear magnetic sample tube 25 , the fourth nuclear magnetic sample tube 31 , and the fifth nuclear magnetic sample tube 32 .

[0026] The top of the electrolytic cell body 1 is affixed to the bottom of the sample tube rotor 2, and the sample tube rotor 2 is provided with a connecting hole 3 for fixing the connecting rod 4, and the bottom end of the connecting rod 4 is connected with the connecting hole 3, and is located in the electrolytic cell. The working electrode 23, auxiliary electrode 26, and reference electrode 28 in the cell body 1 pass through the sample tube cap arranged on the top of the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com