Soil column leaching device

A technology of leaching and soil column, which is applied in the direction of soil material testing, material inspection products, etc., can solve the problems of soil column collapse, sample contamination, etc., and achieve the effect of uniform water distribution and convenient experimental analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

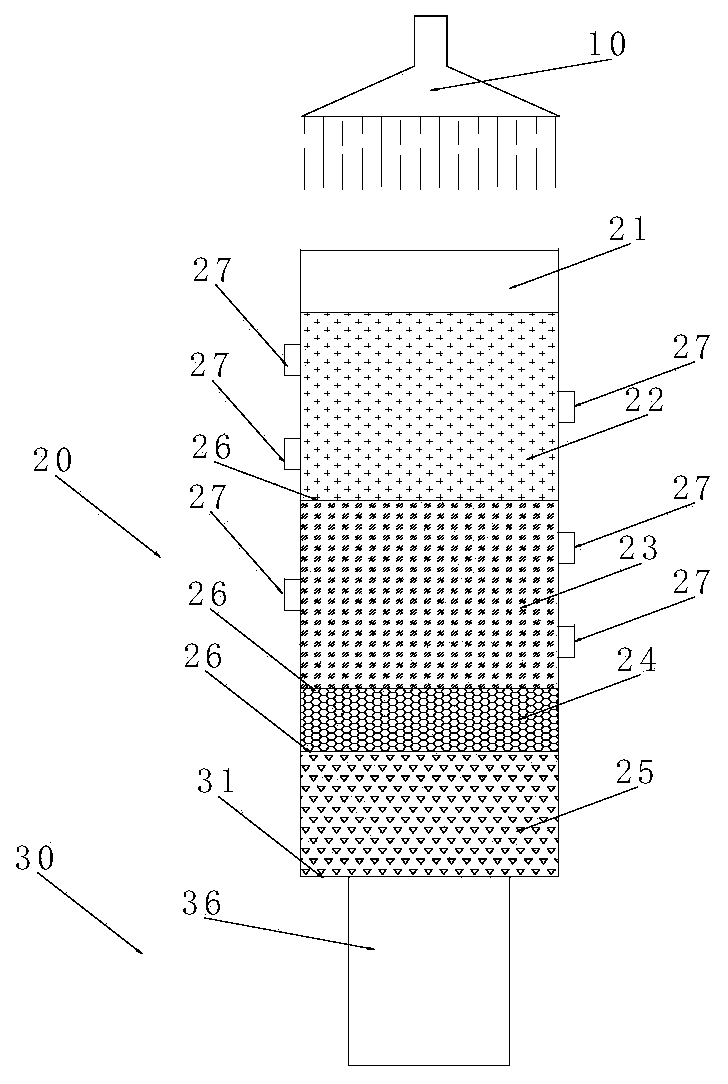

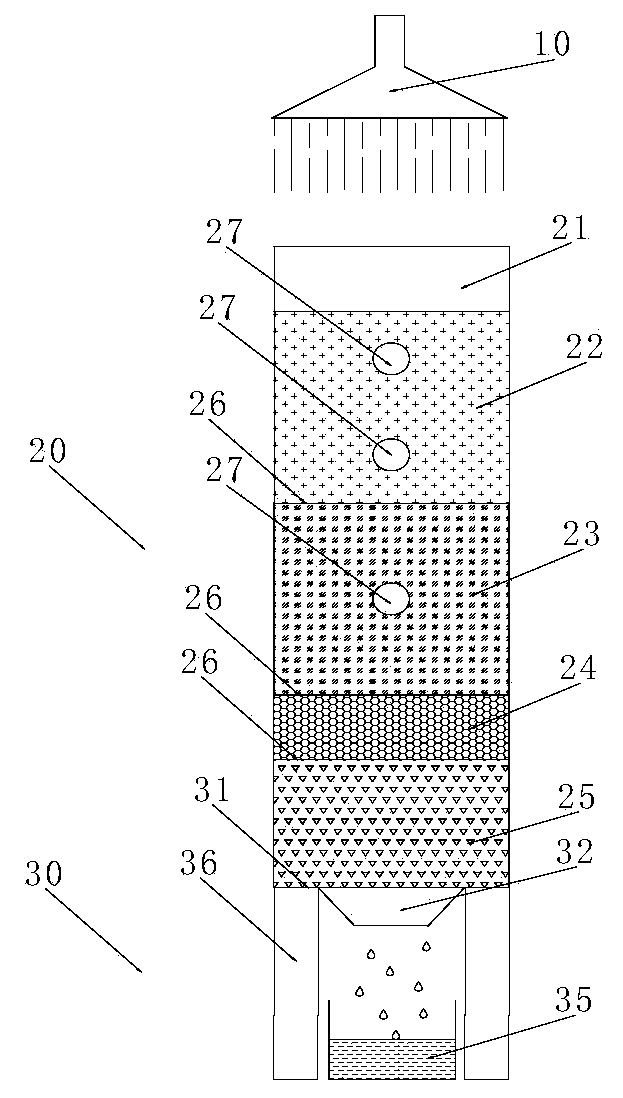

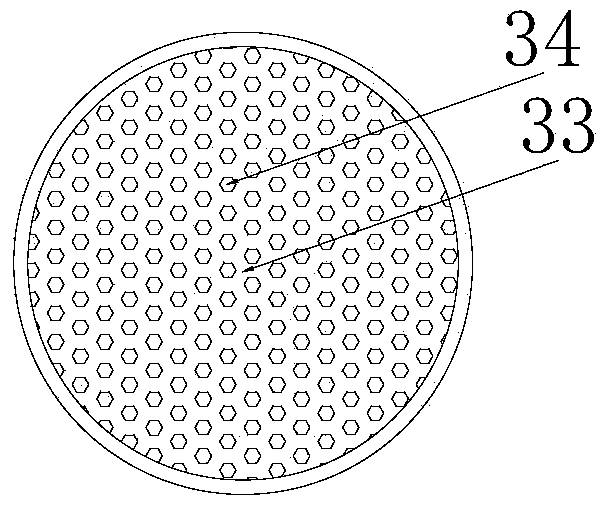

[0021] Embodiment 1 The soil column leaching device of the present invention includes a device body, the upper part of the device body is a leaching area 20, and the lower part is a filtrate filtration area 30, and the top of the device body is equipped with an external The water distributor 10, the leaching zone 20 communicates with the filtrate collection zone 30 through the screen 31 and the porous plate 33; the leaching zone 20 is divided into a buffer layer 21 and a surface soil layer from top to bottom. 22, subsoil layer 23, fine quartz sand layer 24 and coarse quartz sand layer 25, and separate by at least 1 layer filter screen 26 respectively between adjacent layer and layer; There are a plurality of sampling ports 27; the filtrate collection area 30 includes a filter layer 32 at the upper end and a filtrate collector 35 at the bottom, the part extending downwards at the top of the filtrate collection area 30 is used as a support 36, and the The filter layer 32 and the...

Embodiment 2

[0031] Embodiment 2 In conjunction with Example 1 "Research on the Migration Law of Cu and Zn in the Agricultural Vermicompost to the Soil-Plant-Water System under EDTA Leach", the present invention is further described:

[0032] According to the requirements of the experiment, the layers of the leaching zone 20 of the soil column leaching device are filled with corresponding materials, and the topsoil layer 22 is filled with soil for the experiment—the vermicompost that is mixed with fluvo-aquic soil and vermicompost according to the proportion required. The filter screen 26 is separated, and each sampling port 27 is all plugged with a corresponding rubber stopper (not shown in the figure) to prevent water seepage. After the column loading is completed, the stabilization work should be carried out first. Through the external water distributor 10, 100 mL of deionized water is leached for each soil column every day for a total of 15 days, so that the soil particles in the column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com