Method for prolonging life of intelligent control sensor of motor

An intelligent control and life-extending technology, applied in electrical components, circuit devices, emergency protection circuit devices, etc., can solve the problems of pressure sensors, pressure switches, pump motors, shortened life, and high starting frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

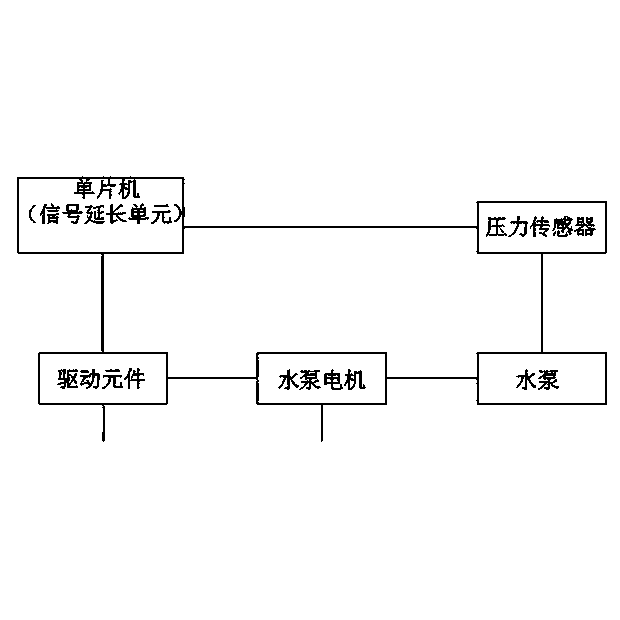

[0014] In this example, if figure 1 As shown, a method for extending the life of a motor intelligent control sensor of the present invention includes a single-chip microcomputer, and a driving element and a pressure sensor that are electrically connected to the single-chip microcomputer respectively, and a water pump motor that is electrically connected to the driving element, and a water pump motor that is electrically connected to the driving element. Drive the connected water pump, the pressure sensor is connected to the water pump; the water pump is provided with a water supply inlet and a water outlet; the single-chip microcomputer is provided with a signal extension unit; The water pump motor is connected externally with a large current-loaded wire, and the drive element is connected with the water pump motor with a large-current load wire.

[0015] Wherein, the pressure sensor is used for real-time measurement of the real-time water pressure in the water pump, and sends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com