Solar cell module installation bracket and installation method

A technology for installing solar cells and components, applied in electrical components, photovoltaic power generation, renewable energy integration, etc., can solve problems such as damage, unevenness, poor matching of gaskets and brackets, etc., and improve the overall structural strength , reduce the cost of bracket materials, and improve the effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

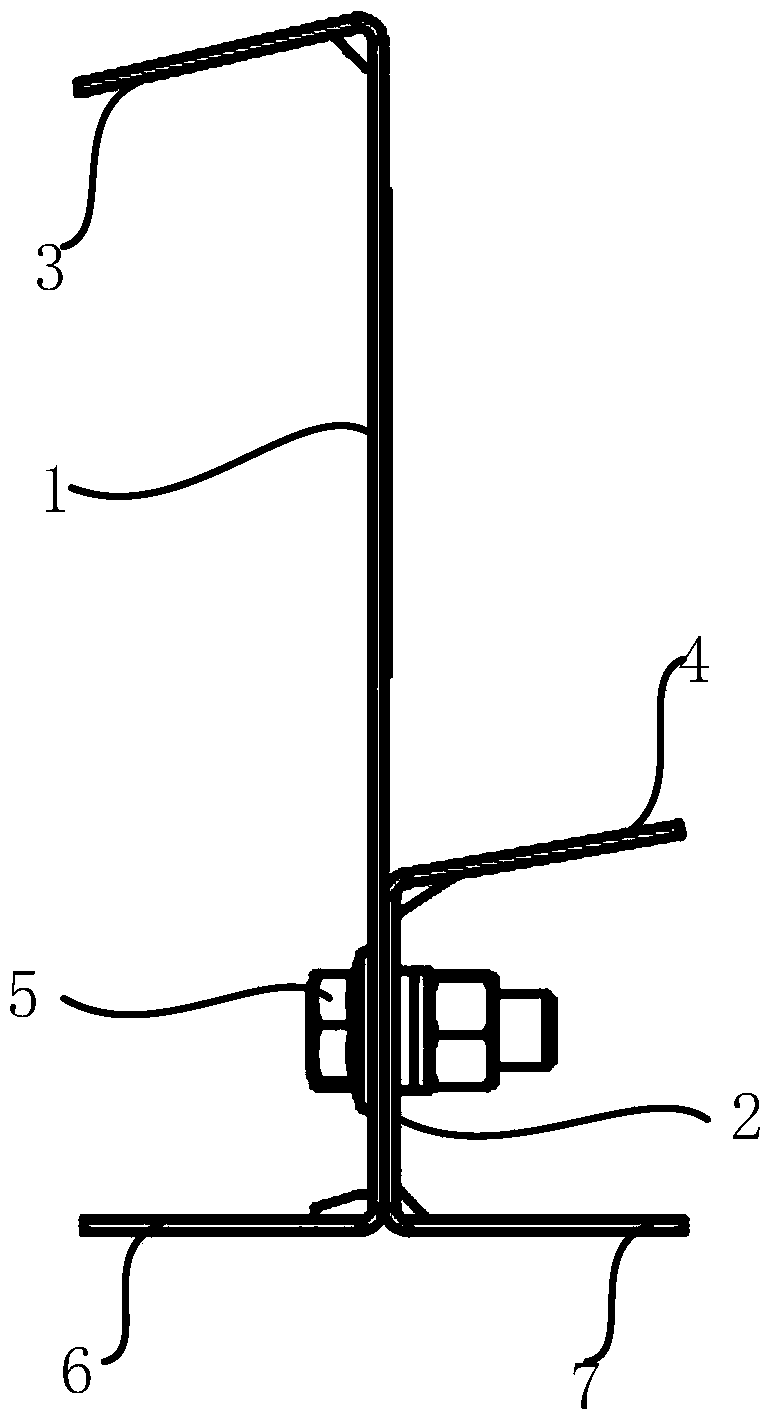

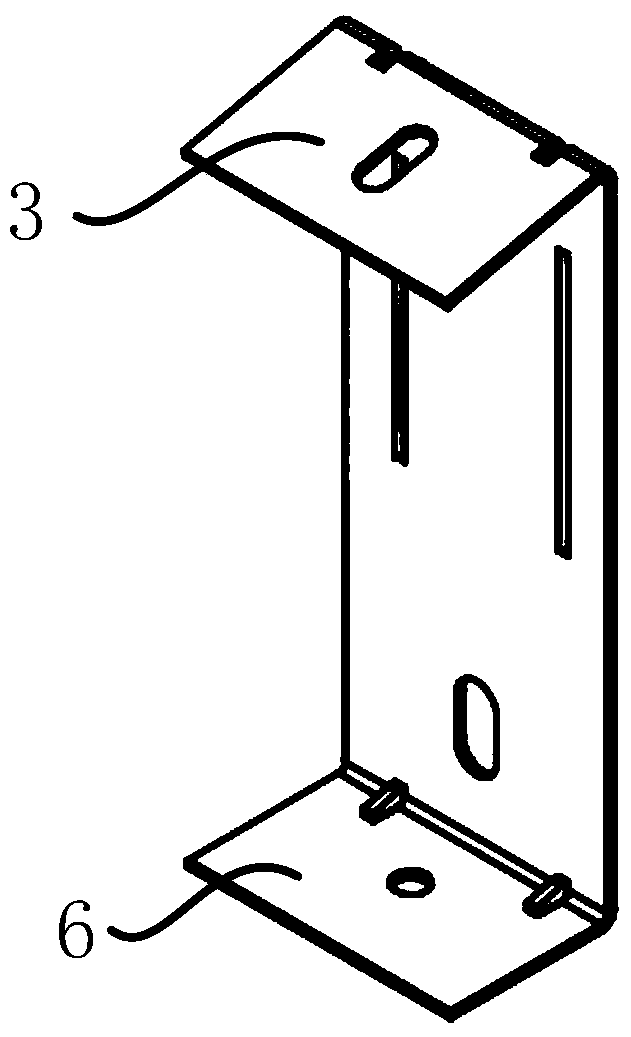

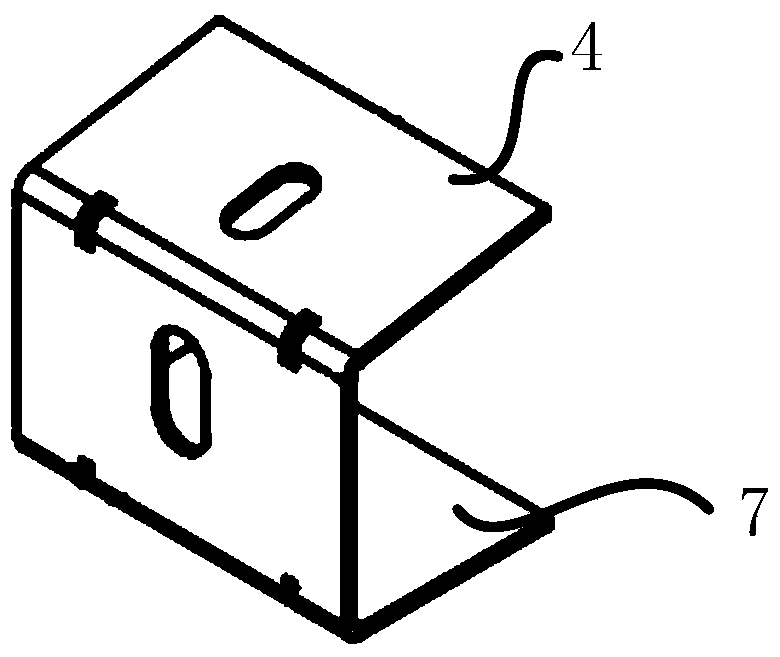

[0073] In this embodiment, the solar cell module installation bracket provided by the present invention includes a first support plate 1 and a second support plate 2; wherein, the first support plate 1 is connected to the second support plate 2; The height of the support plate 1 is greater than the height of the second support plate 2; the top of the first support plate 1 is provided with a first installation part 3 for supporting a solar cell module, and the top of the second support plate 2 is provided with a useful It is used to support the second installation part 4 of another adjacent solar cell module. The first installation part 3 is slightly inclined downward, and the second installation part 4 is slightly inclined upward. The first support plate 1 and the second support plate 2 are U-shaped with lateral openings, such as figure 1 shown.

[0074] The first support plate 1 and the second support plate 2 are provided with at least one reinforcing rib in the vertical di...

Embodiment 2

[0080] In this implementation, on the basis of Embodiment 1, the solar battery module mounting bracket provided by the present invention further includes a base, and the base includes a third fixing portion and a connecting portion that are vertically connected, and the connecting portion is provided with a The first adjustment hole 10 and the third adjustment hole 13 matched with the second adjustment hole 12, the fastener 5 passes through the first adjustment hole 10, the second adjustment hole 12 and the first adjustment hole 12 in turn. Three adjustment holes 13 are used to fix the first support plate 1 and the second support 2 on the base. The first support plate 1 omits the first fixing portion 6 provided at the bottom end, and the second support plate 2 is provided with a second fixing portion 7 at the omitted bottom end. The number of the bases is two, and the two bases are attached and connected back to back. A groove is formed between the fixing parts of the two bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com