Urethane-type curable organic binder for mold, and molding sand composition and mold obtained using same

一种有机粘结剂、聚氨酯的技术,应用在铸型、铸造成型设备、型芯等方向,能够解决可使用时间不充分、无法得到进一步的效果、阻碍胺系固化催化剂催化作用等问题,达到实现可使用时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

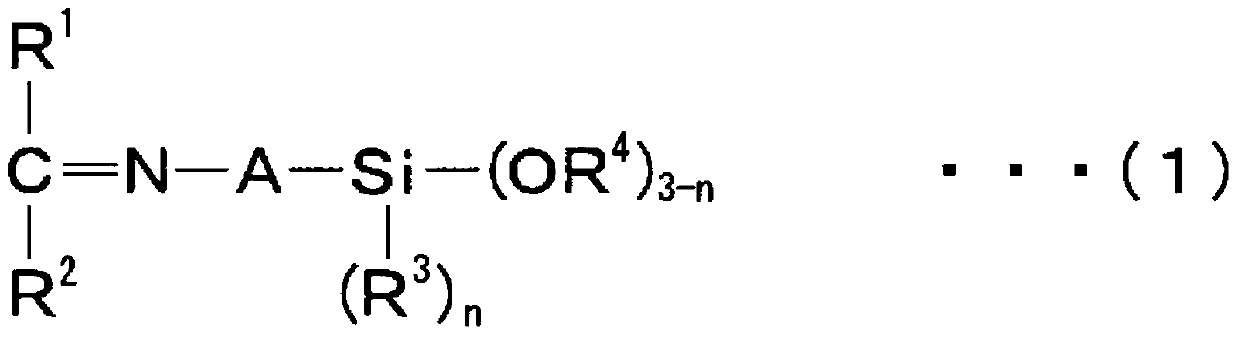

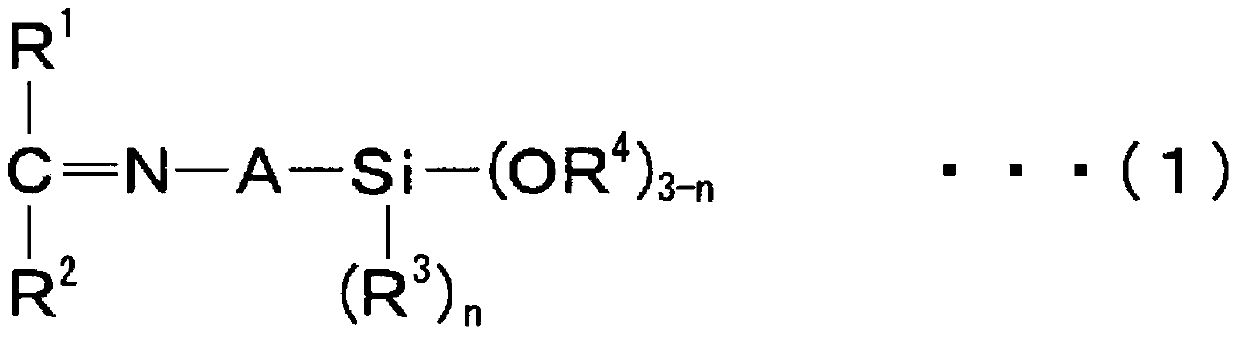

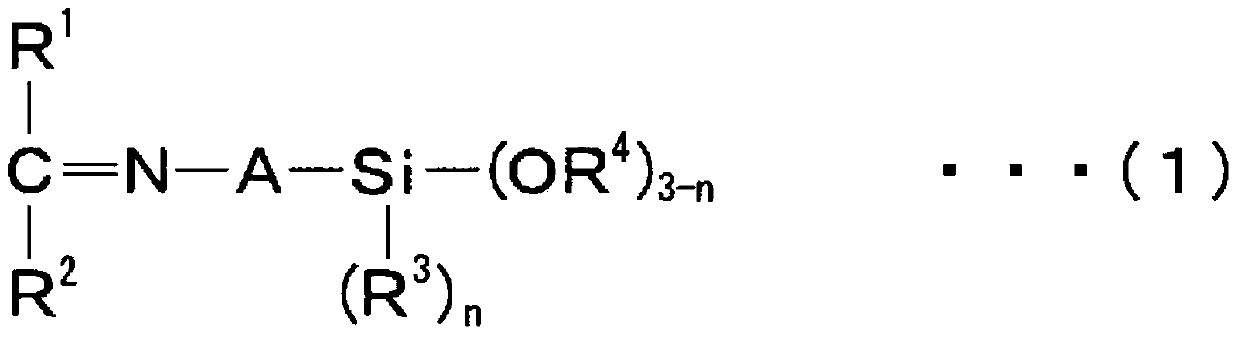

[0068] First, 0.2 parts by mass of N-(1,3-dimethylbutylidene)-3-(triethoxysilyl)-1-propylamine was added to 100 parts by mass of phenolic resin solution A, stirred, and This dissolves it. Next, 1000 parts by mass of Flattery silica sand containing N-(1,3-dimethyl Butylidene)-3-(triethoxysilyl)-1-propylamine 10 parts by mass of phenolic resin solution A and 10 parts by mass of polyisocyanate solution prepared in advance, then stirred and kneaded for 40 seconds to prepare Molding sand coated with an organic binder, that is, a molding sand composition.

[0069] Then, for the obtained molding sand composition, using a composition whose standby time after kneading was 0 minutes (immediately after kneading), 2 hours, or 4 hours, the strength of the mold was measured according to the above-mentioned test method, and the results were They are also shown in Table 1 below.

Embodiment 2~4

[0071] In the preparation of the molding sand composition of the above-mentioned Example 1, N-(1,3-dimethylbutylidene)-3-(triethoxysilyl)- Except for 1-propylamine, it carried out similarly to Example 1, and prepared the molding sand composition of each Example. Then, with regard to the obtained molding sand composition, the measurement of the strength of the mold was carried out using a composition whose standby time after kneading was 0 minutes (immediately after kneading), 2 hours, or 4 hours, and the results are shown together below. Describe Table 1.

Embodiment 5~8

[0073] In the preparation of the molding sand composition of the above-mentioned Example 1, N-(1,3-dimethylbutylidene)-3-(trimethoxysilyl)-1-propylamine was used instead of N-(1,3- Dimethylbutylidene)-3-(triethoxysilyl)-1-propanamine, except that, the molding sand composition was prepared in the same manner as in Examples 1 to 4, and for the obtained molding sand composition , using the composition whose standby time after kneading was 0 minutes (immediately after kneading), 2 hours, or 4 hours, the mold strength was measured, and the results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com