Automatic zipper material counting device

An automatic counting and material technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of consuming a lot of manpower and material resources, difficult to ensure the accuracy and reliability of counting, and difficult data statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

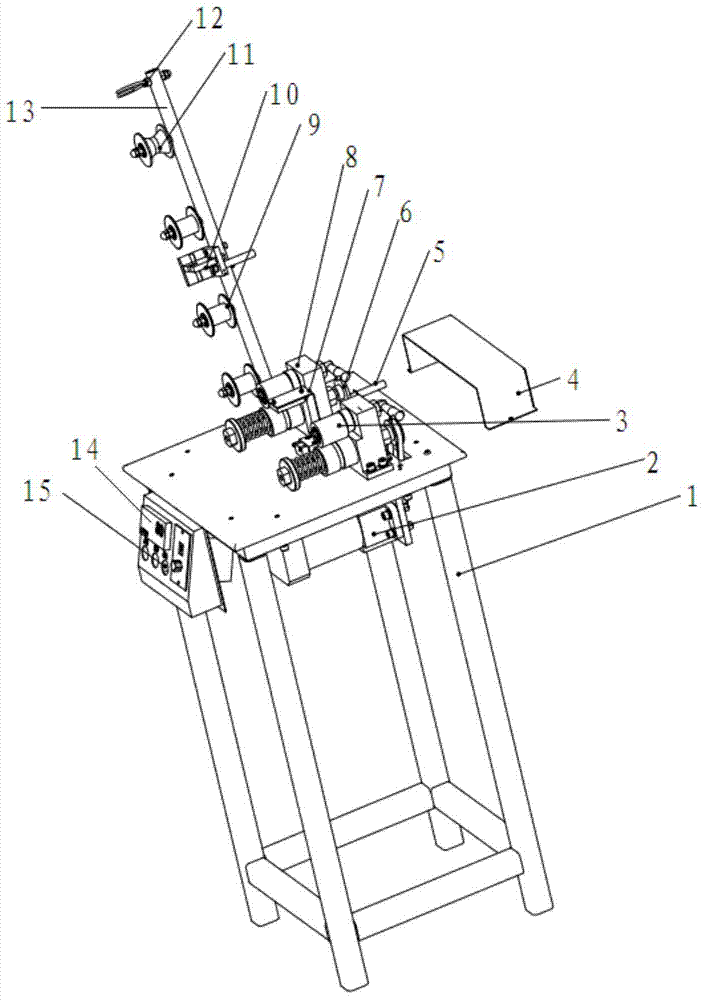

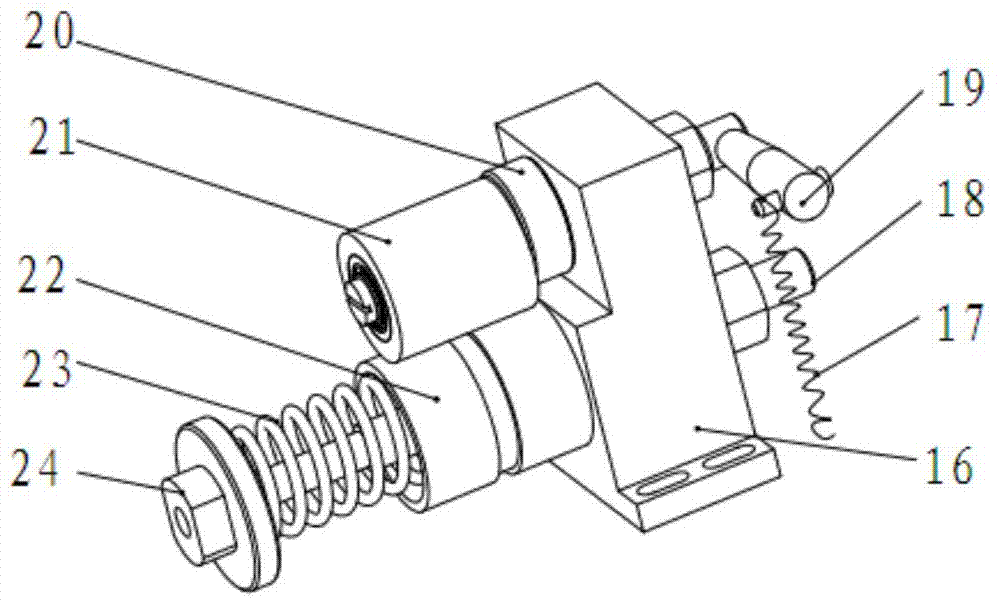

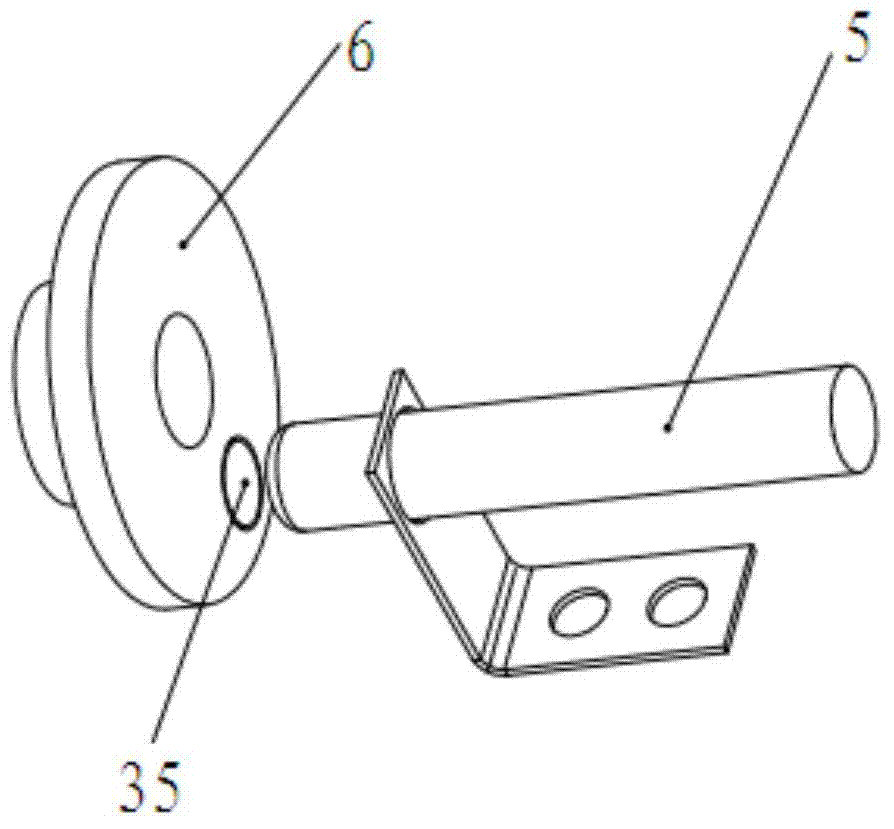

[0017] The main structure of the automatic counting equipment for zipper materials involved in this embodiment includes a main frame 1, a driving motor 2, a main driving mechanism 3, a protective cover 4, a counting detection switch 5, a counting detection plate 6, a material shortage and counting control mechanism 7, a slave drive Mechanism 8, transmission wheel 9, discount detection mechanism 10, feeding guide wheel 11, feeding ring 12, fixed bracket 13, display screen 14 and control unit 15, one end of the main frame 1 of the three-dimensional frame structure is fixedly welded with a rod The fixed support 13 of shape structure, the center of fixed support 13 is fixed with discount detection mechanism 10, and the fixed support 13 on the left and right sides of discount detection mechanism 10 is provided with transmission wheel 9 and feeding guide wheel 11 respectively at equal intervals successively, and fixed support The top of 13 is fixedly welded with a circle-shaped feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com