Single-slot simple iron removal device

A simple, single-slot technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low iron removal efficiency, low degree of automation and work efficiency, and high labor intensity, so as to improve iron removal efficiency. , reduce labor intensity, improve the effect of iron removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

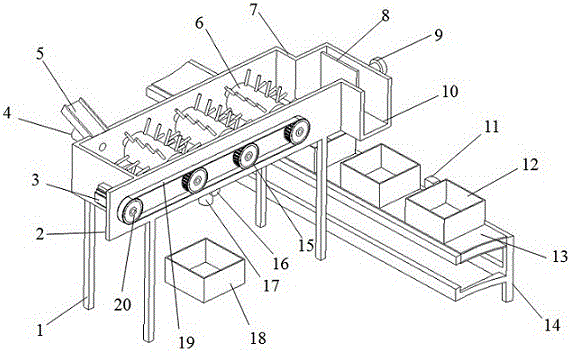

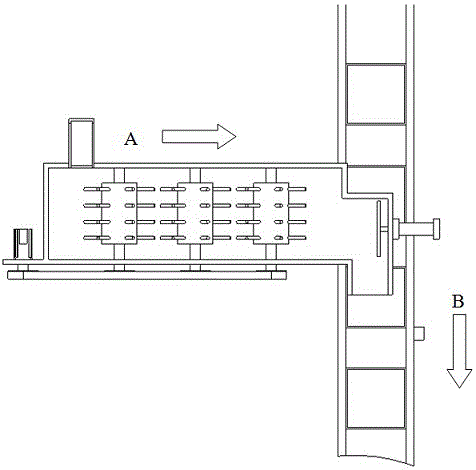

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] control figure 1 and figure 2 Before the device works, the cleaning water inlet 4 is closed, and the sealing cylinder 9 acts to push the sealing plate 8 to move forward to seal the right end outlet of the iron removal tank 7, the iron removal motor 3 is in a power-off state, and the slurry pool 12 is conveyed by the conveyor belt 13 to the Slurry flows to the bottom of the tank 10, and the position sensor 11 detects that the slurry pool 12 is in place and the conveyor belt 13 stops moving, and the slurry enters the iron removal tank 7 from the slurry inlet 5.

[0017] When the slurry in the iron removal tank 7 reaches the specified height, the iron removal motor 3 starts, and the small pulley 20 drives the large pulley 15 to rotate through the belt 19, so that the magnetic bar 6 rotates at a high speed in the slurry to remove iron, and the iron removal is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com