Permanent magnetic adsorbing mechanical arm

A technology of magnetic adsorption and manipulator, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of high power consumption and high cost of use, and achieve the effect of simple structure, low energy consumption and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described:

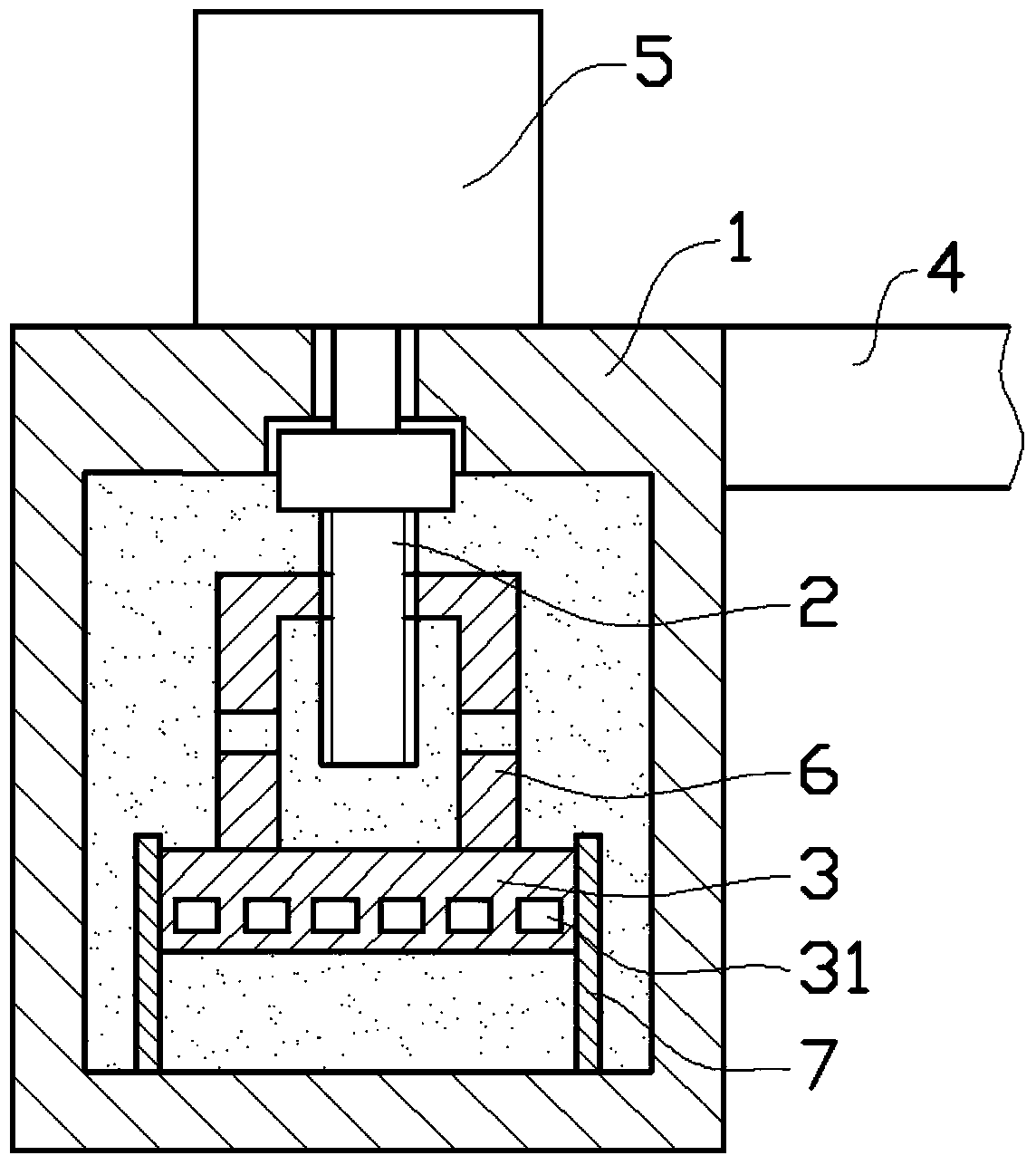

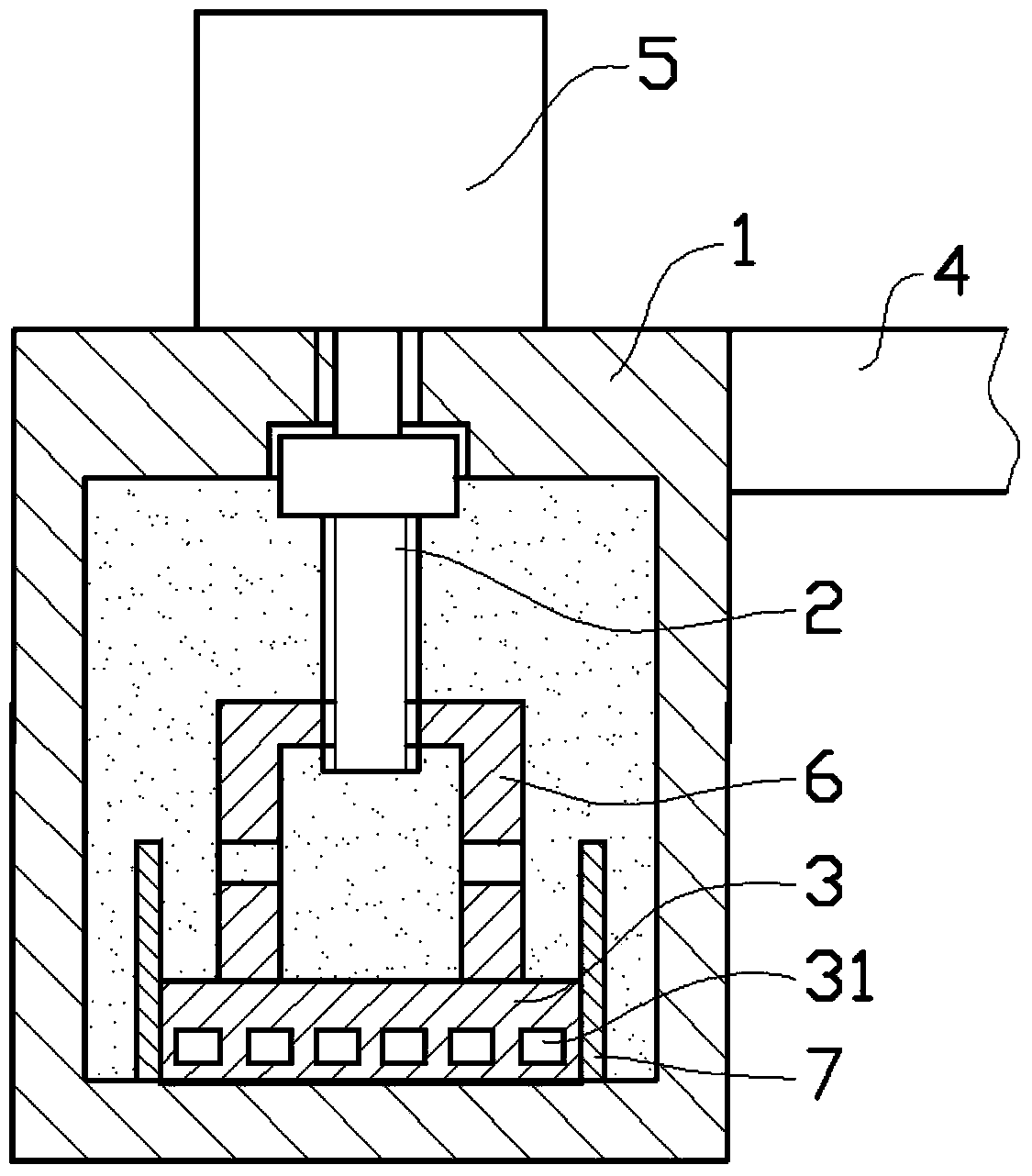

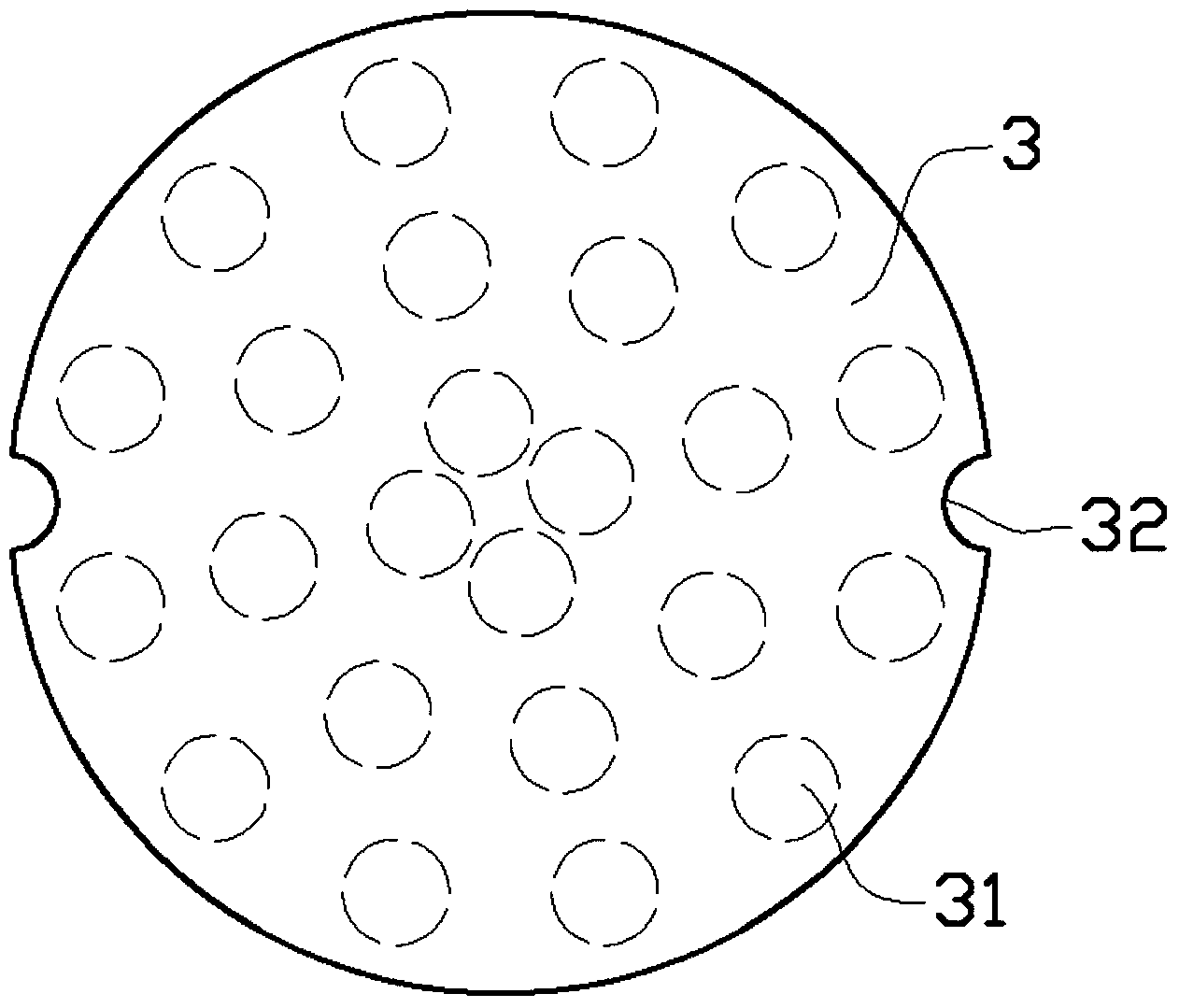

[0012] Such as figure 1 , figure 2 As shown in the embodiment, the permanent magnetic adsorption mechanical arm includes an adsorption box 1, a screw mandrel 2, and a magnetic module 3; Equipped with a rotating motor 5 with a vertical rotating shaft, the rotating output shaft at the bottom of the rotating motor 5 is fixedly connected with the screw 2, the screw 2 goes deep into the inside of the adsorption box 1, and the magnetic module 3 is assembled Inside the adsorption box 1, a connecting column 6 is fixed on its upper part, and the top of the connecting column 6 is processed with a threaded hole for threaded assembly with the screw mandrel 2. The magnetic module 3 is wrapped with a small magnet made of permanent magnetic material. Block 31, the edge position of the magnetic module 3 is designed with a vertical limit column 7 fixed with the adsorption box 1, and the limit column 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com